Automotive manufacturing is an essential part of the modern world. The passenger car industry has brought in $2.29 trillion in revenue, and that number is expected to grow. Everyone uses cars, which means strict safety and traceability standards for manufacturers. Companies that want to meet these standards more efficiently can use laser marking to speed up output without sacrificing quality.

Laser marking uses laser beams to create permanent marks on a material. Depending on the method, laser systems can create labels by vaporizing, heating or chemically altering the material. Laser marks are high-contrast and durable, making them ideal for clear, permanent labels like barcodes and vehicle identification numbers (VINs). Automotive marking is helping businesses modernize without overhauling their entire production line.

Laser marking is becoming a popular choice for auto production lines. This industry needs long-lasting marks on vehicle components to ensure traceability and regulatory compliance. Manufacturers can use laser labeling for:

Auto manufacturers are turning to laser imprinting over traditional methods like inkjet, stamping or mechanical engraving. Direct part marking for automotives offers:

Laser marking automotives also helps companies meet strict industry compliance standards. In the United States, auto manufacturers must follow regulations for part documentation.

The National Highway Traffic Safety Administration (NHTSA) requires VINs on parts for high-theft vehicles in 49 CFR Part 541. According to 49 CFR 574, tire manufacturers need to put identifying numbers on their tires before retail sales. Other standards, like the International Automotive Task Force (IATF), published IATF 16949:2016 to give manufacturers a guide for quality control.

Marks should be permanent, legible and tamper-resistant. This system simplifies product recalls and ensures critical components are traceable. Laser marking meets these standards and promotes traceable products for automakers.

If you’re interested in a laser marking machine for automotives, you need to go beyond choosing a power rating. The system must match your materials, production volume, components and other needs to perform effectively.

Auto producers work with a range of materials. Aluminum, stainless steel, coated metals, composites and high-performance plastics all have different compositions. Choose a laser source that aligns with your material:

High-volume production demands fast, consistent results. Laser power, fill settings, pulse width and beam delivery all affect system throughput. Galvo-driven scan heads offer rapid beam steering and are well-suited for high-speed, high-accuracy imprinting. If you need complex or deep labels, use adjustable pulse duration via MOPA (master oscillator power amplifier) technology to fine-tune performance.

Laser systems must accommodate part size and geometry. Adjustable lens options allow manufacturers to tailor the marking field while maintaining resolution. Consider rotary attachments for cylindrical parts like exhaust housing. For oddly shaped parts, modular designs make fitting the system to the part form simple.

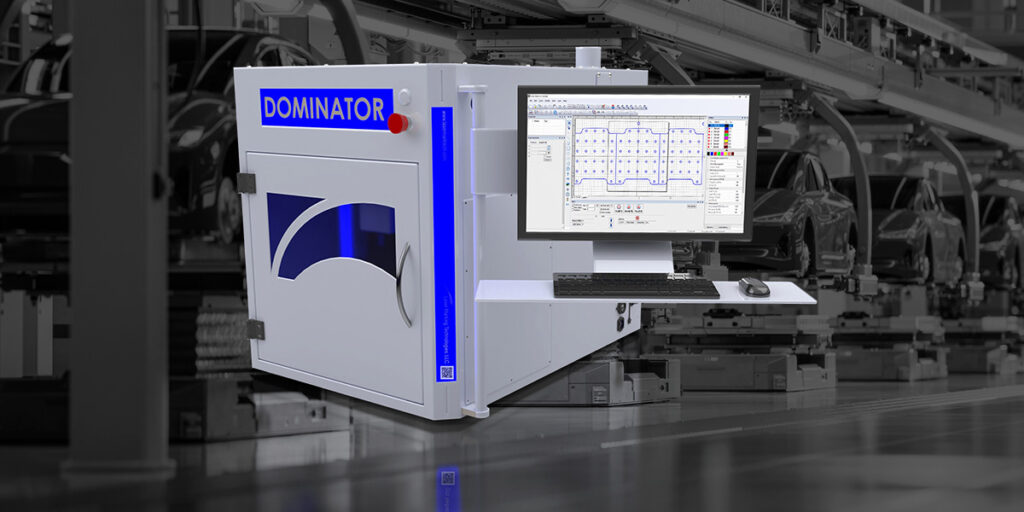

Does the system integrate with your existing setup? Labeling equipment must work with your production line to avoid delays and expensive overhauls. Dominator and Cobalt systems are designed for direct communication with FANUC and UR robots for automated part handling. Look for software features that integrate with enterprise systems for easier mark placement and serialization.

Finally, ensure the system you select complies with industry standards and general safety protocols. Invest in systems with enclosed Class 1 safety ratings, interlocked doors and fail-safes. Additionally, invest in operator training. The better trained your team, the safer and faster they can work.

Automotive manufacturers need equipment that can keep pace with different materials, part designs and industry demands. Laser Marking Technologies offers an advanced lineup of laser labeling systems built to handle all your auto-marking needs. Here’s how each laser imprinting machine type can help:

Fiber lasers are favored for their high power density, reliability and precision. Use fiber machines with beam qualities tailored for metals to create permanent, abrasion-resistant marks. LMT’s Cobalt® Dominator and Cobalt® XD PRO are ideal for imprinting metals with sharp, permanent engravings.

CO2 lasers are optimized for organic and nonmetallic materials. Use them for clean, consistent marks on plastics, leather, rubber and composite surfaces. Machines like the Dominator® CO2 system will mark components without contact, allowing you to place aesthetic or functional marks without affecting integrity.

UV lasers have a short wavelength — around 355 nanometers — which lets them cold-mark sensitive or heat-resistant materials. This option prevents deformation on delicate surfaces. The Dominator® UV system has automation features and high-speed galvo steering. Deliver precise marks on small pieces while moving through production quickly.

Green laser systems are less popular than fiber, CO2 and UV, but they can fill in the gaps. Use green 532-nanometer lasers on soft plastics, ceramics and epoxy resins. The Dominator® G532 laser system creates fine labels on small components without cracking or damaging them. Its low thermal transfer makes it suitable for labeling highly sensitive surfaces.

Whatever your automotive marking needs, Laser Marking Technologies delivers the precision, compliance and performance you require. Our U.S.-made systems are built for traceability and fast-paced production. No matter your labeling demands, we offer the equipment and support to help you meet high quality standards and tight regulations.

With over 100 years of combined experience, 24/7 product technical support and the best warranties in the industry, you can count on LMT to go above and beyond for your business. We even offer installation and training services to ensure your team makes the transition smoothly. Contact us today for a demo and learn how our systems can integrate directly into your automotive workflow.