1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

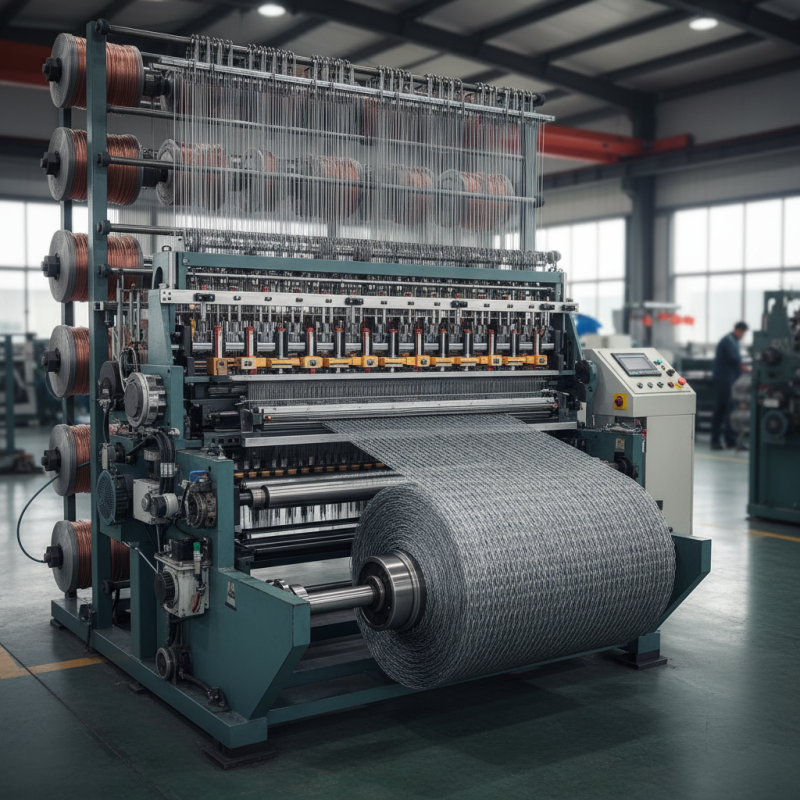

A wire mesh weaving machine is a crucial tool in various industries. It efficiently produces wire mesh for construction, agriculture, and security applications. The machine weaves wires together, forming a strong grid structure. This process offers both precision and speed, ensuring high-quality output.

Understanding how a wire mesh weaving machine works can be fascinating. The machine uses intricate mechanisms to intertwine the wire strands. Different patterns can be created, depending on specific requirements. The choice of material and weaving style significantly impacts the final product.

While the technology is advanced, challenges remain. Some machines may struggle with specific wire types or thicknesses. This can lead to inefficiencies or defects in the final mesh. Reflection on these issues can guide improvements in design and operation.

A wire mesh weaving machine is essential in various industrial applications. It is designed to create wire mesh products used in construction, manufacturing, and agriculture. These machines can handle different types of wire materials, such as stainless steel and galvanized wire. The weaving process typically involves interlacing wires in a specific pattern to achieve desired mesh sizes and strengths.

According to recent industry reports, the global wire mesh market is projected to grow significantly in the coming years. In 2022, it was valued at approximately $7 billion, with a compound annual growth rate of around 5.2%. This growth indicates an increasing demand for high-quality wire mesh products across multiple sectors. Despite advancements in technology, some machines still struggle with precision and efficiency. Users often report lace-like inconsistencies in the mesh produced, leading to product rejection.

The operational mechanism of these machines is straightforward. They usually consist of a feeding system, weaving heads, and a collection unit. As wires are fed into the machine, they are woven together under controlled tension. However, achieving the correct tension can be problematic. Operators must constantly monitor the process to avoid defects. This balancing act of speed and quality can sometimes lead to frustrating experiences on the production floor.

Wire mesh weaving machines are fascinating pieces of equipment used in numerous industries. The key components of these machines are crucial for their operation. One important part is the wire feeding mechanism. This system supplies wire accurately and ensures consistent tension throughout the weaving process. If the tension is too loose or too tight, it can lead to defects in the mesh.

Another critical component is the weaving head. This part interlaces the wires together, forming the desired mesh pattern. Different patterns require various configurations of the weaving head. Sometimes, improper alignment can affect the mesh's quality. Operators need keen attention to detail to avoid these common pitfalls.

Additionally, the cutting mechanism plays a significant role. After weaving, the mesh needs to be cut to specific sizes. An efficient cutting system minimizes waste and enhances productivity. However, if the machine settings are incorrect, it could lead to uneven cuts. All in all, understanding these components is essential for optimizing the wire mesh weaving process.

The wire mesh weaving machine operates on a systematic framework. It interlaces wires through various techniques to produce mesh products. These machines typically work with stainless steel, galvanized metal, or other materials. Adjustments in tension and feed rates affect the mesh quality produced. For accurate dimensions, the weaving process must be precise.

Some industry reports show that a well-calibrated machine can achieve a production rate of up to 200 meters per hour. This efficiency highlights the importance of operational principles. The warp and weft lines form a crisscross pattern. This is fundamental for strong, durable mesh. However, operators must monitor tension levels regularly. Inconsistent tension may lead to defects like uneven spacing or weak spots.

Additionally, the choice of wire gauge impacts the final product. A thinner wire may mean increased flexibility but can compromise strength. Specifications often dictate the preferred wire size for specific applications, but variances can occur. Operators must be cautious; mishandling can lead to further issues during production. Monitoring and adjustments are essential for maintaining quality standards. The intricacies of the weaving process demand ongoing attention and evaluation for optimal performance.

Wire mesh weaving machines play a vital role in producing various types of wire mesh used across numerous industries. The machines are designed to weave wire strands into intricate patterns, resulting in different mesh types. Common types include welded wire mesh, woven wire mesh, and stainless steel wire mesh. Each type has its unique properties and applications. For instance, welded wire mesh is often used in construction for reinforcement, while woven wire mesh serves filtration needs.

The global wire mesh market is expected to reach a value of approximately $10 billion by 2025, according to industry reports. This growth reflects the increasing demand for wire mesh in construction and agriculture. Woven wire mesh, in particular, is renowned for its flexibility and strength. It is often employed in landscaping and animal enclosures. However, challenges remain in quality control during production. The weave quality can vary, leading to potential weaknesses in the final product.

Additionally, the choice of material impacts wire mesh performance. For example, stainless steel offers corrosion resistance but can be more expensive than other materials. Balancing cost and quality remains critical for manufacturers. Despite advancements in weaving technology, ensuring consistent output quality invites ongoing reflection and improvement in production processes. The industry must adapt to varying demands and materials while maintaining high standards.

Wire mesh weaving machines play a crucial role in various industries by producing high-quality wire mesh products. These machines are essential in construction, agriculture, and manufacturing. They create a variety of mesh types, such as welded, woven, and crimped wire mesh.

In construction, wire mesh is widely used for reinforcement. It strengthens concrete structures, making them more durable. In agriculture, wire mesh protects crops from pests and animals. Farmers often use mesh to create fences or cages. Additionally, in manufacturing, wire mesh is crucial for filtration systems and processing.

Tips: When selecting a wire mesh weaving machine, consider the materials' compatibility. It affects the final product's quality. Regular maintenance of the machine is vital too. Neglecting it can lead to costly repairs.

Wire mesh weaving machines have many applications. However, some users overlook their specific requirements. A miscalculation can lead to production delays. Understanding the needs of your industry will help ensure efficiency.