1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

Laser etching is a powerful technique for creating custom designs on various materials. It offers precision and fine detail that is hard to achieve through traditional methods. This technology uses focused laser beams to remove material, leaving behind intricate patterns and images.

For artists and businesses, laser etching is a game-changer. It allows for unique branding opportunities and personal expressions. Imagine a beautifully etched wooden box or a glass award with a customized logo. These items capture attention and convey a message.

Yet, working with laser etching comes with challenges. Artists must understand material selection, laser settings, and design software. Often, trial and error reveals unforeseen difficulties. Some designs may not translate well from concept to etching. Reflecting on these missteps is essential for growth in this technique. Ultimately, embracing the learning process enhances creativity and accuracy in laser etching projects.

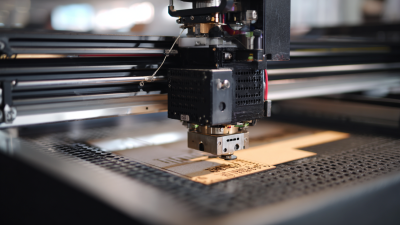

Laser etching technology is revolutionizing the way we customize designs. This process uses high-powered lasers to engrave precise patterns onto various materials. From metal to wood, the versatility of laser etching is impressive. The intense focus of the laser allows for fine details that traditional methods struggle to achieve. The designs can be intricate, drawn from a digital file, and reproduced with remarkable accuracy.

Applications of laser etching are vast. Artists and designers use it to create unique artworks and personalized gifts. Businesses employ laser etching for branding purposes. Custom logos can be etched onto products, making them instantly recognizable. However, it’s not always perfect. Sometimes the etching depth may vary, leading to inconsistent results. Adjusting settings can be tricky, especially for beginners. It requires patience and experience to master the technique.

Even so, the creativity unleashed through laser etching is undeniable. Whether for art, industry, or personal use, the potential is immense. Mistakes can occur, but each one teaches a valuable lesson. Continuous experimentation can lead to breakthroughs in design and execution. This evolving technology invites anyone to explore their creativity, making precise custom designs accessible to all.

When selecting materials for laser etching projects, various options can impact the final result. Wood is popular. It offers a natural texture and grain. However, not all woods work equally well. Softer woods tend to etch deeply, while harder woods provide finer details. Different finishes can also affect the outcome. Untreated surfaces generally yield better results.

Acrylic is another excellent choice for etching. It comes in various colors and thicknesses. The clarity of acrylic can enhance designs dramatically. Yet, choosing the right thickness is crucial. Too thick a material may warp during the process. Thinner sheets may crack. It’s essential to find a happy medium.

Metal surfaces, such as aluminum or stainless steel, allow for stunning, durable designs. However, they require special settings. It’s easy to miscalculate power levels, leading to incomplete etches. Sometimes, an incorrect focus can spoil the piece. Testing on scrap material is always a wise move. Each material has its quirks, warranting careful consideration before starting your project.

| Material Type | Best Uses | Etching Depth | Finish Type |

|---|---|---|---|

| Acrylic | Awards, Signs | 0.05 - 0.1 mm | Smooth, Glossy |

| Wood | Furniture, Art | 0.1 - 0.5 mm | Natural, Rustic |

| Metal | Industrial Parts, Jewelry | 0.1 - 0.4 mm | Brushed, Matte |

| Glass | Awards, Decor | 0.1 mm | Frosted, Clear |

| Leather | Accessories, Products | 0.1 - 0.3 mm | Soft, Textured |

Creating custom designs for laser etching requires a clear approach.

Start by brainstorming ideas. Sketch your concepts on paper.

Consider the material you will etch.

Different materials react differently to laser settings. This is vital for achieving desired effects.

Once you have a solid design, move to digital software. Use vector-based programs for precision.

Simplify complex designs to avoid mistakes during the etching process. Sometimes, less is more.

Test your design on a similar scrap material. This allows for adjustments without wasting your main material.

Finally, configuration is crucial. Adjust the laser settings based on your material and design details.

Observe how different speeds and powers affect the outcome.

Achieving the perfect etch might require a few trials. Be willing to learn from errors.

Each attempt could reveal new possibilities for your designs.

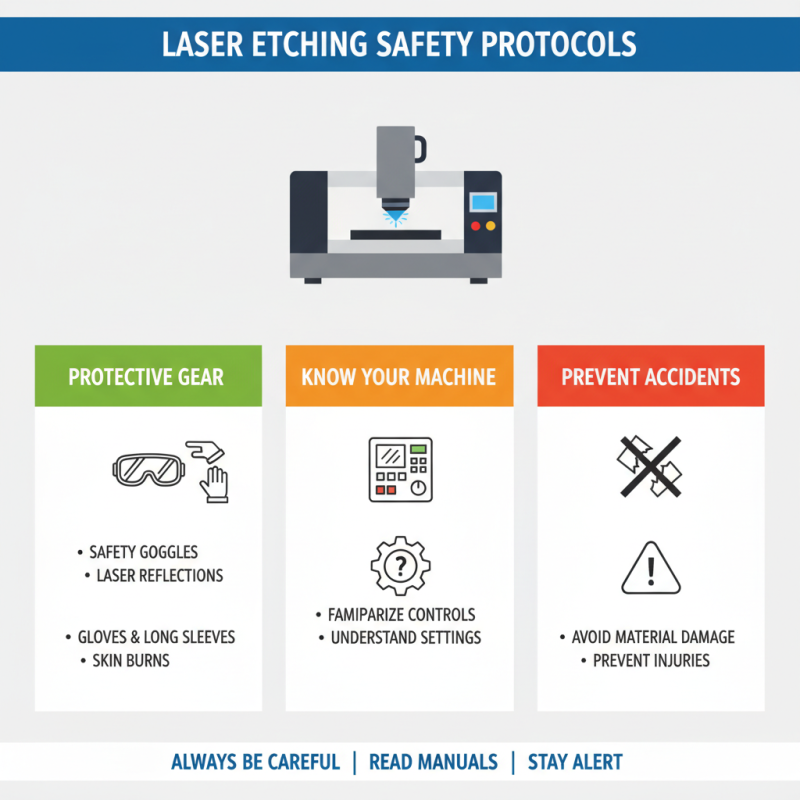

Operating a laser etching machine requires careful attention to safety. Always wear protective gear. Safety goggles are essential to guard against laser reflections. Gloves and long sleeves can protect your skin from potential burns. Familiarize yourself with the machine’s controls and settings before use. Each machine is different. Misunderstanding the controls can lead to accidents or damaged materials.

Ensure your workspace is organized. Keep flammable materials away from the machine. Have a fire extinguisher nearby just in case. Ventilation is crucial as laser etching produces fumes. Set up a proper exhaust system to avoid inhaling harmful particles. It’s easy to overlook these details. Even an experienced user can become complacent, so stay alert.

Practice makes perfect. Begin with simple designs before tackling complex projects. Mistakes will happen, but they provide valuable learning experiences. Sometimes the etching might not align correctly. Reflect on what went wrong and adjust accordingly. It’s part of the process. Each attempt, regardless of the outcome, brings you closer to mastery.

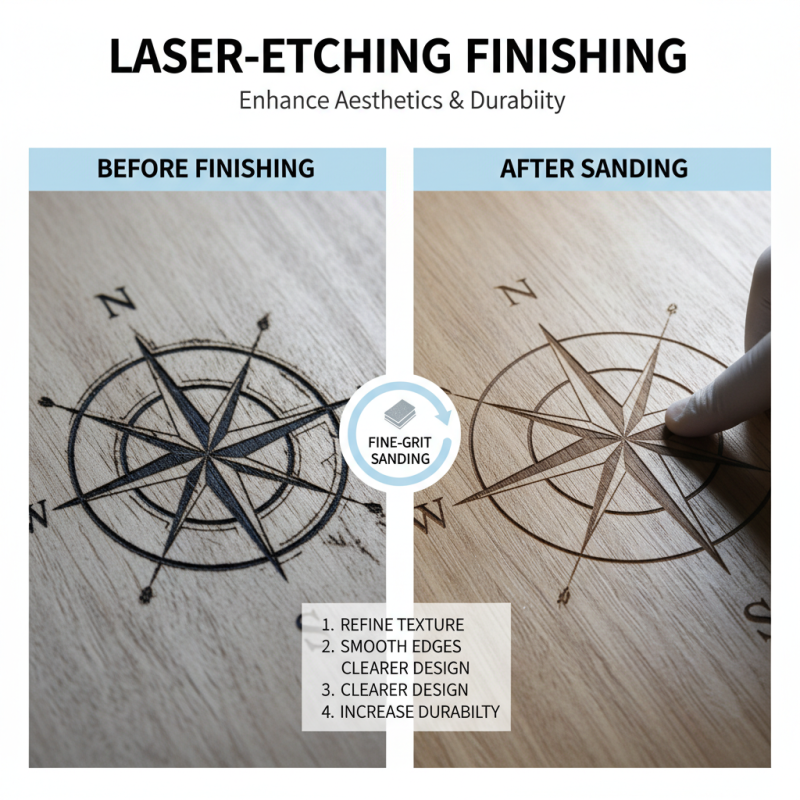

Post-etching finishing techniques play a crucial role in enhancing both the aesthetics and durability of laser-etched designs. After the etching process, surfaces may appear rough or uneven. Sanding is a practical approach to refine the texture and smooth the edges. Use fine-grit sandpaper for a subtle finish. This step allows the design to shine through more clearly.

Applying a protective coating can further improve the lifespan of the etching. Clear varnishes or specialty sprays create a barrier against scratches and UV damage. However, it’s vital to test these coatings on a sample piece first. Some finishes may alter the intended look of the design. A careful selection can ensure a lasting brilliance without sacrificing visual appeal.

Lastly, polishing can elevate the appearance. Buffing the surface brings out a nice sheen. Nevertheless, over-polishing can ruin the intricacies of the etching. It's essential to find a balance. Observing how different materials react to finishing techniques can provide valuable insights for future projects.