1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

In recent years, the adoption of laser marking technology has significantly transformed industrial branding and traceability solutions across various sectors. According to a report by MarketsandMarkets, the global laser marking market is projected to reach USD 6.8 billion by 2025, growing at a CAGR of 6.5% from 2020. This surge is primarily driven by the increasing demand for efficient and precise marking solutions, which enhance product identification and quality assurance. Laser marking offers a permanent solution that withstands harsh conditions, making it ideal for industries such as automotive, electronics, and pharmaceuticals, where traceability is critical. Furthermore, the ability to incorporate complex designs and dynamic data, such as QR codes and serial numbers, has revolutionized branding efforts, streamlining supply chain operations and improving customer engagement. As industries continue to prioritize durability and accuracy, laser marking stands at the forefront, reshaping how businesses approach product identification and quality management.

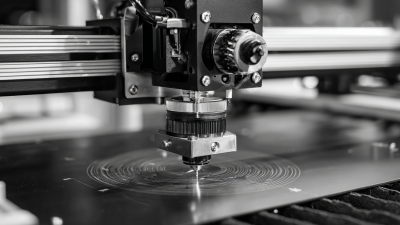

Laser marking technology has evolved significantly over the past few decades, transforming the landscape of industrial applications. Initially developed for basic engraving tasks, modern laser marking systems now utilize advanced techniques that provide high precision and versatility. This evolution is largely driven by the need for enhanced branding and traceability solutions across various sectors, including manufacturing, electronics, and medical devices. Today’s laser markers can produce intricate designs and codes on a wide range of materials, ensuring robust product identification while enhancing customer engagement.

One of the most notable advancements in laser marking technology is the integration of automation and artificial intelligence. These innovations have allowed for real-time tracking of products throughout the supply chain, significantly improving traceability. With the ability to customize markings and encode vital information directly onto products, businesses can ensure compliance with industry standards and regulations while facilitating swift responses to recalls or quality control issues. As industries continue to pursue efficiency and quality, the adaptability and precision of laser marking technology will play a crucial role in shaping the future of industrial branding and traceability solutions.

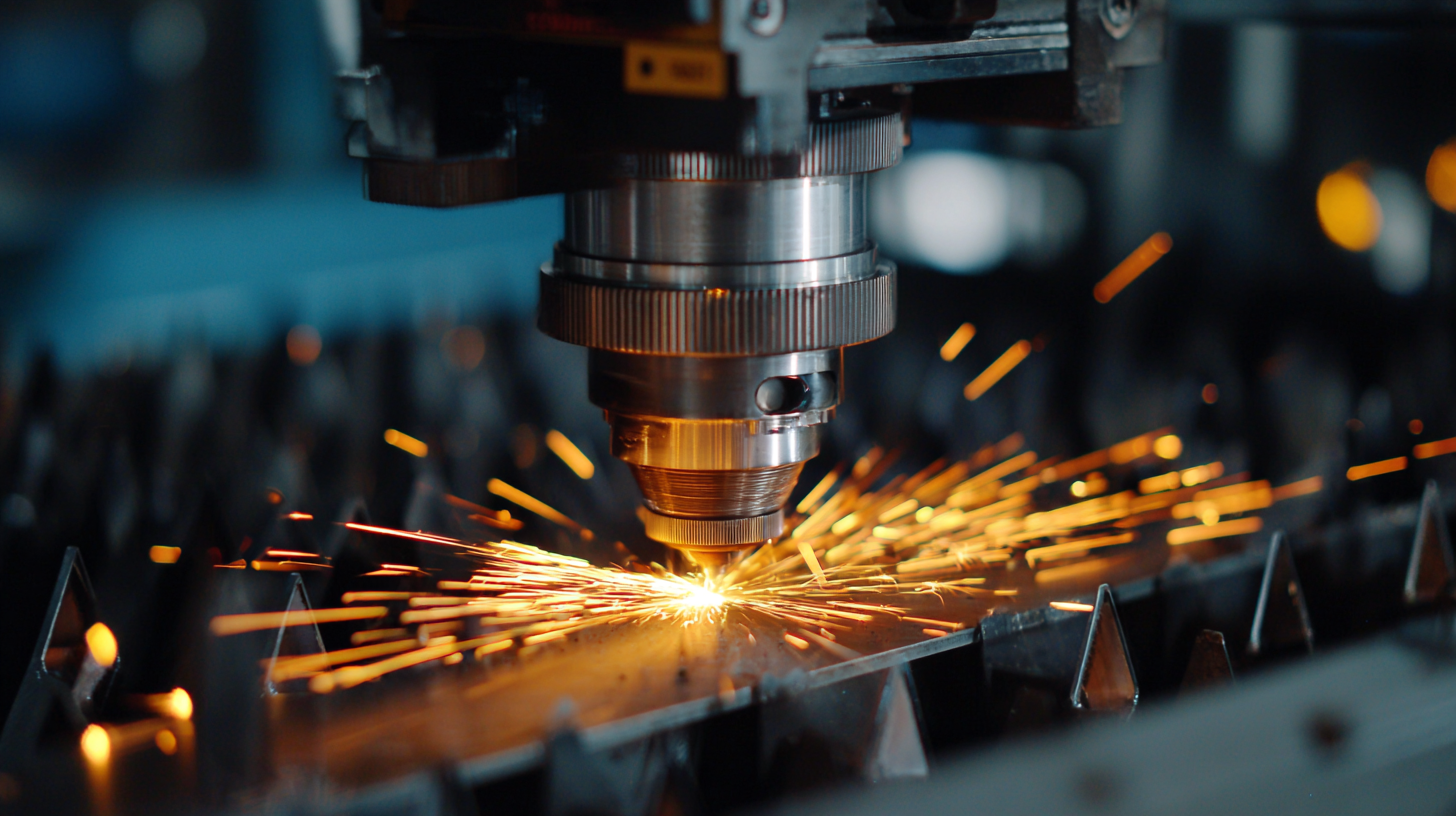

Laser marking has emerged as a game-changing technology in the realm of industrial branding and traceability. One of the key advantages of laser marking for brand identity enhancement is its precision. Unlike traditional marking methods, laser marking allows for intricate designs and logos to be etched onto various materials with unparalleled accuracy. This level of detail not only enhances the visual appeal of products but also establishes a strong connection to the brand, ensuring that it stands out in a competitive marketplace.

Another significant benefit is the durability of laser markings. The process creates permanent marks that are resistant to fading, scratching, and various environmental damages. This longevity contributes to a lasting brand presence, as the markings will remain intact throughout the product's lifecycle. Furthermore, laser marking can also incorporate elements like QR codes or serial numbers, which bolster traceability and provide customers with access to vital product information. By integrating branding with advanced traceability solutions, companies can strengthen customer trust and brand loyalty.

Laser marking technology is significantly transforming supply chain traceability and compliance in various industries. As the global marking and coding equipment market is projected to grow from USD 7.8 billion in 2025 to USD 13.8 billion by 2035, manufacturers prioritize traceability, compliance, and automation. This shift underscores the critical role laser marking plays in ensuring accurate product identification, which is essential for meeting regulatory requirements and enhancing supply chain transparency.

The laser marking market alone is anticipated to reach USD 4.58 billion by 2030, primarily driven by the increasing adoption of fiber lasers and a growing demand for traceability solutions. These advancements empower manufacturers to implement effective serialization practices, which have become standard in sectors like pharmaceuticals. For instance, the rise of pharmaceutical serialization practices exemplifies the urgent need for reliable marking solutions that enhance product safety and accountability across the supply chain.

Tips for Enhancing Traceability:

- Integrate digital product passports to provide detailed product information and improve traceability in your manufacturing processes.

- Utilize 2D barcodes and digital links to enable real-time data access, ensuring compliance with retailer and regulatory standards.

- Invest in automated marking systems to streamline operations and improve efficiency while maintaining high compliance levels.

The adoption of laser marking technology has seen remarkable growth across various industries, reflecting a significant shift towards more efficient branding and traceability solutions. According to a report by MarketsandMarkets, the global laser marking market was valued at approximately $2.49 billion in 2021 and is projected to reach around $4.62 billion by 2026, growing at a CAGR of 13.3%. This rapid expansion indicates that businesses are increasingly prioritizing precision and durability in their marking processes, essential for compliance with industry standards.

Furthermore, a study by Fior Markets highlights that the automotive sector is currently leading in laser marking applications, driven by the need for high-quality identification methods that can withstand harsh environments. The research estimates that laser marking adoption in this sector is poised to grow significantly, with a projected CAGR of 15% from 2022 to 2028. This trend is mirrored in the electronics and medical industries, where reliable traceability is critical—characteristics that laser marking uniquely fulfills. Overall, these statistics underscore an important transition towards advanced marking technologies that enhance product integrity and consumer trust in the marketplace.

Laser marking has emerged as a cornerstone technology in industrial branding and traceability, offering distinct advantages over traditional marking methods. Unlike conventional techniques such as inkjet or dot peen marking, which often compromise on durability and precision, laser marking ensures high-resolution output and resilience against environmental factors. This capability is particularly crucial in manufacturing where product identification and traceability are vital for quality control and compliance with industry standards.

The industrial laser market is experiencing significant growth, driven by advancements in laser technologies like CO2, solid-state, diode, and fiber lasers. These technologies are categorized based on power output, with applications ranging from low-power (<1 kW) for delicate materials to high-power (>1.1 kW) for robust fabrication processes. Industries are increasingly adopting laser marking for macro processing applications, enhancing operational efficiency, and providing a sustainable alternative to chemical-based marking methods. The competitive edge offered by laser marking in traceability and branding is likely to propel its adoption across various sectors, solidifying its role in shaping the future of manufacturing.