1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

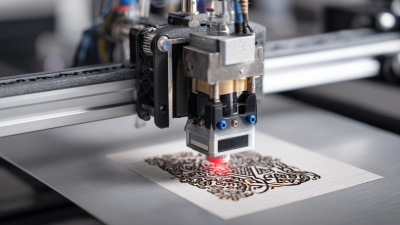

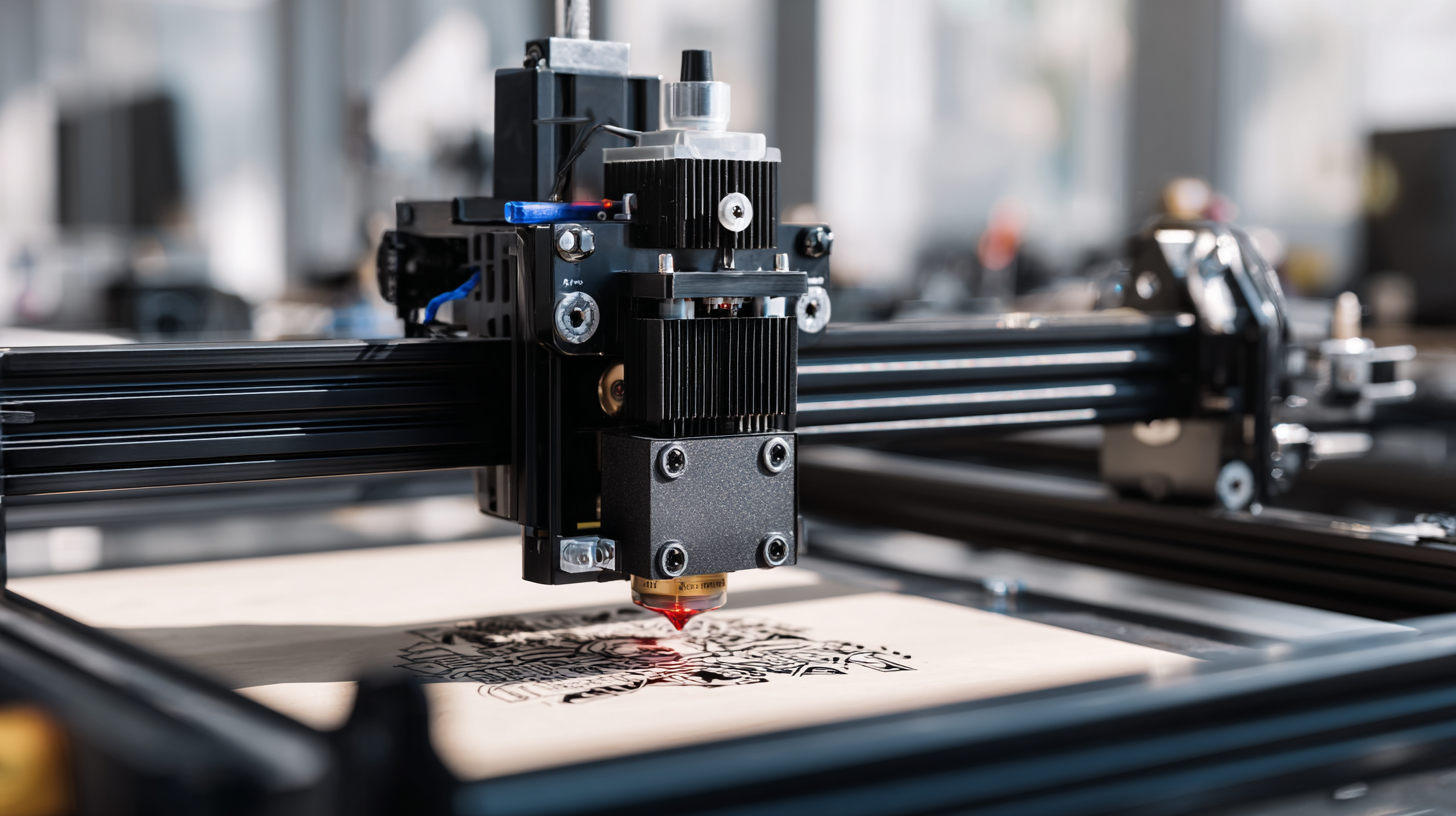

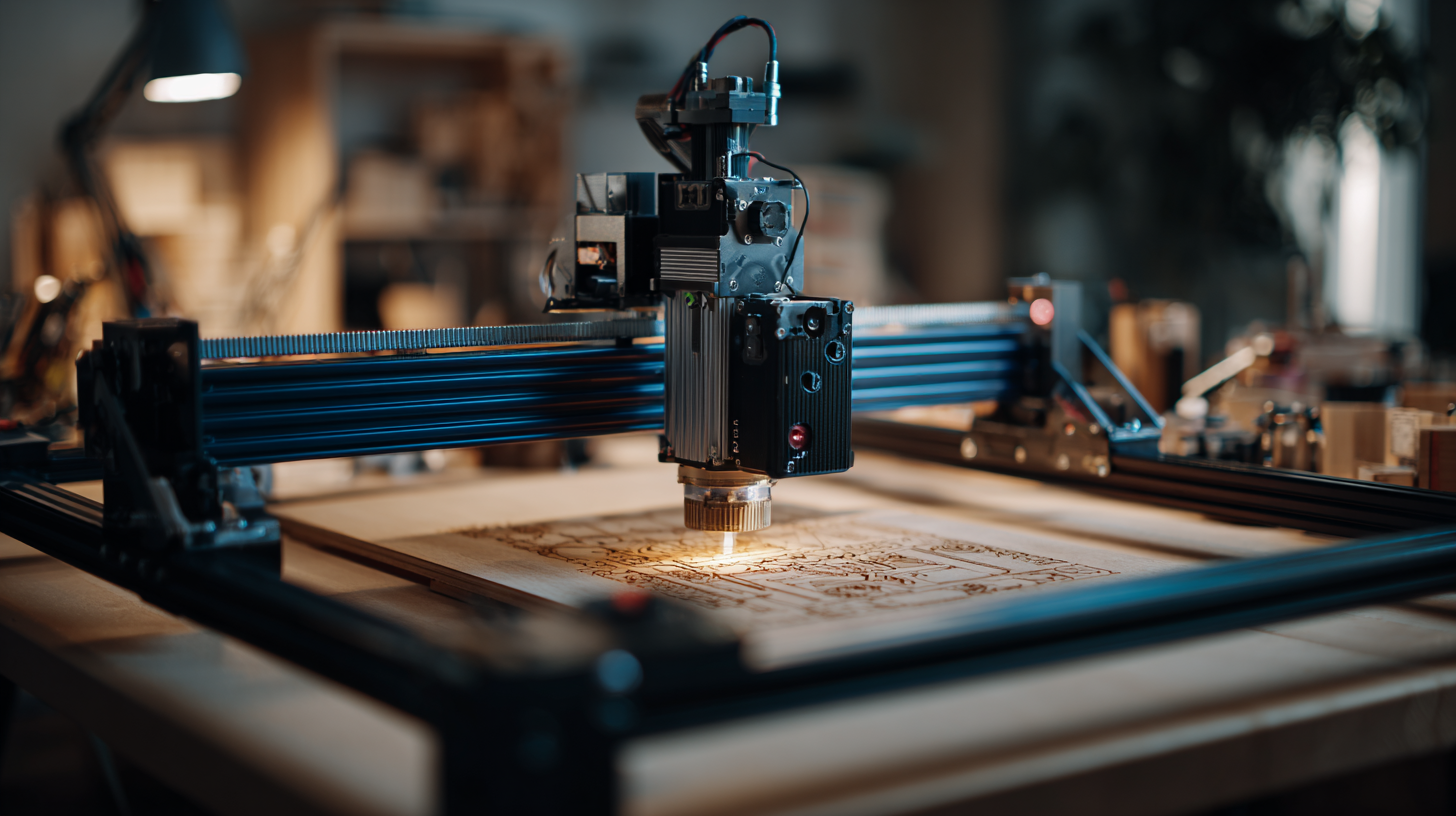

In today's rapidly evolving creative landscape, selecting the best laser engraving machine is crucial for artists and entrepreneurs looking to enhance their craft and streamline production. According to a recent industry report by Research and Markets, the laser engraving market is projected to reach USD 5.04 billion by 2025, growing at a CAGR of 5.1%. This growth is fueled by the increasing demand for personalized products and the expansion of the e-commerce sector, where unique engravings can significantly elevate the perceived value of items. Furthermore, advancements in laser technology have made it more accessible for hobbyists and professionals alike, enabling diverse applications across various materials including wood, glass, and metal. With such high stakes, understanding the features and specifications of the best laser engraving machine becomes essential for achieving outstanding results in any project.

When selecting a laser engraving machine for your creative projects, several key features should be at the forefront of your decision-making process. Firstly, consider the laser type. CO2 lasers are excellent for engraving a wide range of materials, including wood, acrylic, and glass, while fiber lasers are more suited for metals. Choose a machine that aligns with the materials you plan to work with to ensure optimal results.

Another critical factor is the machine's power and speed. Higher wattage typically translates to faster engraving and deeper cuts, making it essential for larger or more intricate designs. Additionally, look for a machine with adjustable settings, allowing you to fine-tune the engraving depth and speed based on the material. Other features to consider include the engraving area size, connectivity options (such as USB or Wi-Fi), and software compatibility, as these can significantly enhance your crafting experience. By carefully evaluating these features, you can select a laser engraving machine that truly enhances your creativity and meets the demands of your projects.

| Feature | Description | Importance Level |

|---|---|---|

| Laser Type | CO2 lasers are ideal for wood, acrylic, and glass, whereas fiber lasers are best for metals. | High |

| Power Output | Higher wattage allows for faster engraving and cutting. | High |

| Working Area | Larger working area allows for bigger projects and versatility. | Medium |

| Software Compatibility | Compatibility with design software ensures ease of use. | High |

| Cooling System | Efficient cooling systems help maintain optimal performance. | Medium |

| Safety Features | Features like automatic shutoff and enclosure ensure safe operation. | High |

| Price | Pricing varies based on features; consider your budget and project needs. | Medium |

When it comes to laser engraving, the type of machine you choose can significantly impact the outcome of your projects. There are several categories of laser engraving machines, each designed for different materials and applications. CO2 laser engravers, for instance, are versatile options that work well on wood, acrylic, glass, and leather. According to a report by IBISWorld, the demand for CO2 laser cutting machines has grown by over 5% annually, reflecting their popularity among hobbyists and professionals alike.

On the other hand, fiber laser engravers are ideal for marking metals and are increasingly favored in industrial settings. These machines are known for their precision and speed, making them suitable for high-volume production runs. A market analysis from MarketsandMarkets projects that the fiber laser market will reach USD 5.5 billion by 2026, driven by advancements in technology and an expanding range of applications across various sectors. By understanding the strengths of each type of laser engraver, you can select the perfect machine that aligns with your creative needs and project requirements.

This chart compares the average prices of different types of laser engraving machines, helping you to understand which machine fits your budget and project requirements.

When selecting a laser engraving machine, budgeting is a critical factor that requires a balance between cost and quality. Recent reviews have identified notable models that cater to different financial plans while still delivering impressive performance. For instance, the Creality Falcon A1 emerges as an excellent choice for beginners on a budget. This model offers versatile capabilities, successfully cutting and engraving various materials, making it perfect for those who want to explore their creative potential without overspending.

It’s essential to consider performance metrics alongside the price tag. For example, high-end models are often recommended based on their speed, accuracy, and overall finish quality. Industry reports suggest that investing a little more can yield significantly better results, especially for projects that demand precision. Additionally, assessing long-term costs, such as maintenance and material compatibility, ensures that your investment remains within budget while meeting your creative needs effectively.

Balancing these aspects will help you find a laser engraving machine that not only fits your financial plans but also enhances your creative projects.

When it comes to owning a laser engraving machine, proper maintenance and care are crucial to ensuring its longevity and optimal performance. Regularly cleaning the lenses and mirrors is one of the most important tasks. Dust and residue can affect the quality of your engravings, so use a soft cloth or a specialized lens cleaning solution to keep these components clear. Additionally, check the alignment of the laser beam periodically; a misaligned beam can lead to uneven results and increase wear on the machine.

Another vital aspect of maintenance is lubrication. Regularly lubricate moving parts as per the manufacturer’s guidelines to prevent wear and tear. Keeping the machine free from debris and ensuring that belts and rails are in good condition will contribute to smoother operation and enhance engraving precision. Lastly, don’t forget to update the software and firmware to ensure you're utilizing the latest features and enhancements for your equipment, making a significant difference in your creative output.

When it comes to laser engraving, choosing the right software and design tools is crucial to maximizing your projects. Laser engraving machines often require specific compatibility with design software to ensure smooth operation and optimal results. Many users report that employing high-quality design software can drastically enhance the quality of the finished product.

According to industry studies, 68% of users find that software compatibility directly influences their productivity and the quality of their engravings.

To reduce raw material waste during the cutting process, automatic nesting tools are essential. These tools allow users to arrange designs efficiently on the material, minimizing scrap. Research shows that implementing nesting strategies can reduce material waste by up to 30%, significantly lowering costs for businesses and DIY enthusiasts alike.

Tips: