1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

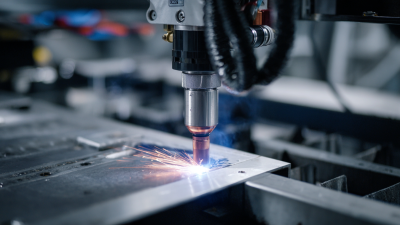

The landscape of industrial manufacturing is rapidly evolving, with laser welding machines taking center stage as a key solution for innovative welding applications. According to a report by Market Research Future, the global laser welding machine market is projected to reach USD 1.43 billion by 2025, growing at a compound annual growth rate (CAGR) of 5.6% from 2019 to 2025. This growth is fueled by the increasing demand for precision and efficiency in various industries, including automotive, aerospace, and electronics.

As manufacturers seek to enhance productivity and reduce operational costs, laser welding machines offer unparalleled advantages, such as minimal thermal distortion and high-speed processing capabilities. The versatility of these machines is paramount; they can seamlessly weld a wide range of materials, from metals to plastics, making them essential in modern production environments. In this context, we will explore the top five laser welding machines to watch in 2025, shedding light on the innovations these technologies bring to the industry and how they can propel manufacturers toward a more automated and efficient future.

Laser welding is a cutting-edge technology that enhances precision and efficiency in joining materials. For beginners, it’s essential to understand that laser welding utilizes focused beams of light to melt and fuse metals together. This method offers several advantages over traditional welding, including deeper penetration, minimal distortion, and the ability to weld thin sections effectively. The technology operates by directing a high-energy laser beam onto the workpiece, which creates a molten pool that cools quickly to form a solid weld.

One of the key aspects of laser welding technology is its versatility. It can be used across various industries, from automotive manufacturing to electronics and medical devices. The ability to adjust the laser's intensity and speed allows operators to tailor the welding process to different materials and thicknesses, making it ideal for complex geometries.

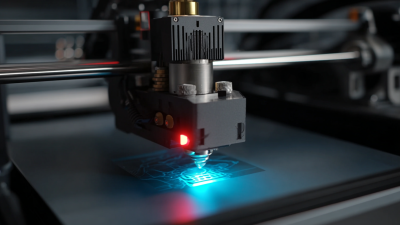

Furthermore, the automation potential of laser welding boosts production rates and ensures consistent quality, which is vital for modern manufacturing. For newcomers, familiarizing themselves with these fundamental principles will pave the way for deeper exploration into laser welding applications and innovations expected in the coming years.

As the demand for precision and efficiency in manufacturing continues to rise, next-gen laser welding machines are set to revolutionize the industry by 2025. When evaluating these innovative machines, several key features should stand out. Firstly, improved beam quality is essential, as it directly influences penetration depth and weld integrity. Machines with higher power settings and adjustable focus help achieve better results, particularly for diverse materials. According to a report by MarketsandMarkets, the laser welding market is projected to reach $2.2 billion by 2025, highlighting the importance of investing in advanced technology.

Another feature to consider is automation capabilities. Modern laser welding machines increasingly incorporate AI and IoT technologies, enhancing operational efficiency and accuracy. A study by Grand View Research indicates that automation in welding could boost productivity by 30%, making it a worthwhile investment for companies striving for competitive advantage.

**Tips:** Always assess the machine’s compatibility with existing systems, as integration is crucial for maximizing productivity. Additionally, look for machines that offer easy-to-use interfaces and robust customer support to facilitate training and troubleshooting. Lastly, consider machines with energy-saving features, as sustainability is becoming increasingly important in manufacturing processes.

Laser welding technology has been gaining significant traction across various industries due to its ability to provide innovative and efficient solutions. With the growing demand for precision and speed in manufacturing, laser welding is revolutionizing processes ranging from automotive to electronics. The application of laser welding allows for the joining of materials without the need for additional fillers, minimizing waste and enhancing structural integrity.

Tips for exploring laser welding applications:

1. Consider the type of materials being used. Laser welding is highly effective for metals, plastics, and composites, making it versatile for different sectors.

2. Stay informed about advancements in laser technologies such as fiber lasers and solid-state lasers, which can offer better efficiency and lower operational costs.

As industries evolve, the need for advanced laser welding solutions is expected to expand. The market for laser welding technology is projected to see significant growth, especially as manufacturers seek to adopt more sustainable practices. Embracing cutting-edge laser welding machines can lead to improved productivity and quality in production processes.

As industries continue to embrace automation and precision manufacturing, the demand for laser welding machines is set to soar. A recent report by MarketsandMarkets estimates that the global laser welding market will grow from $4.03 billion in 2022 to $7.67 billion by 2027, at a CAGR of 13.7%. This growth presents a ripe opportunity to explore the top five laser welding machines projected to lead the market in 2025, each promising innovative solutions tailored for specific applications.

Firstly, companies are increasingly looking for machines that not only enhance productivity but also deliver superior weld quality and reduced preparation time. Advanced models, such as those equipped with fiber laser technology, are predicted to dominate the sector. According to the International Journal of Advanced Manufacturing Technology, fiber lasers offer higher efficiency and better beam quality compared to traditional CO2 lasers, making them preferable for critical applications in automotive and aerospace industries. The comparative analysis of these top machines will reveal how features like built-in automation, real-time monitoring systems, and energy management contribute to minimizing operational costs while maximizing output.

In addition, the focus on sustainability is shaping the development of laser welding technologies. As highlighted by a report from Grand View Research, the integration of eco-friendly practices in welding processes will significantly impact machine selection in the future. Machines that utilize green energy sources and minimize waste production will not only appeal to environmentally conscious manufacturers but also comply with tightening regulations globally. The anticipated advancements in laser welding technology are set to provide solutions that meet the evolving requirements of modern industries.

| Machine Model | Welding Speed (m/min) | Laser Power (kW) | Material Compatibility | Features |

|---|---|---|---|---|

| Model A | 2.5 | 2 | Steel, Aluminum | Automatic Focus Adjustment |

| Model B | 3.0 | 3 | Stainless Steel | Advanced Cooling System |

| Model C | 1.8 | 1.5 | Carbon Steel | High Precision Control |

| Model D | 4.0 | 4 | Titanium, Aluminum | Integrated Software for Analysis |

| Model E | 2.2 | 2.5 | Copper, Brass | User-Friendly Interface |

In the rapidly evolving field of laser welding, future design trends and efficiency solutions are poised to revolutionize the industry by 2025. According to a report by ResearchAndMarkets, the global laser welding market is expected to reach $3.4 billion by 2026, growing at a CAGR of 5.7% from 2021. This increase is largely driven by advancements in laser technology that enhance precision and minimize heat input, leading to superior weld quality and reduced distortion in welded components.

One key trend is the integration of artificial intelligence (AI) in laser welding machines to optimize parameters in real-time, thus improving efficiency and accuracy. A study published in the Journal of Manufacturing Processes highlights that AI-driven systems can increase productivity by up to 50% through adaptive learning and automatic adjustments during the welding process. Furthermore, the development of compact and portable laser welders is gaining traction, making them more accessible for small to medium-sized enterprises, which represent 90% of all businesses globally, according to the World Bank. This shift towards efficiency and versatility ensures that laser welding remains a competitive and innovative solution for various manufacturing applications.