1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

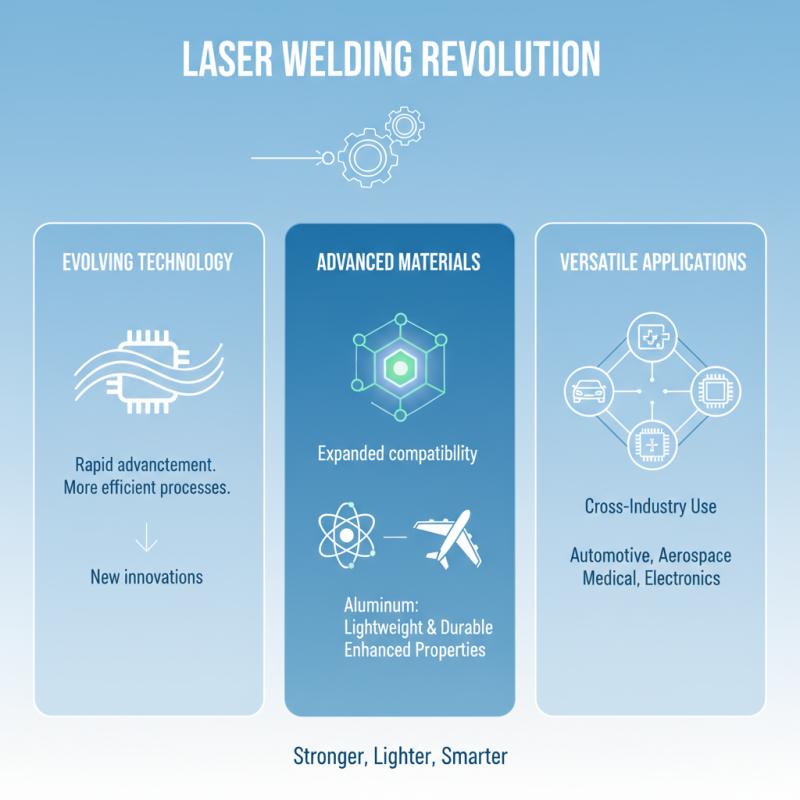

In 2026, the landscape of laser welding machines continues to evolve. Innovations and trends shape industries from automotive to aerospace. These machines enhance precision and efficiency, critical factors in modern manufacturing.

New technologies emerge, pushing boundaries. For instance, adaptive laser systems allow for real-time adjustments. They can optimize weld quality under varying conditions. However, relying on technology raises questions about skills in the workforce. Are traditional welding skills at risk of fading away?

Moreover, sustainability remains a vital focus. Companies seek eco-friendly solutions in their processes. The demand for energy-efficient laser welding machines increases. Yet, it’s essential to reflect on the broader implications of such advancements. Will they truly benefit the environment? As we explore the latest trends, it’s crucial to consider both the opportunities and challenges ahead.

The landscape of laser welding technology is rapidly evolving as we approach 2026. New advancements are shaping the industry's future. Reports show that the global laser welding market is expected to grow by over 5% annually, reaching approximately $6 billion by 2026. This growth highlights the increasing demand for precision and efficiency in manufacturing processes.

Emerging technologies focus on optimizing performance and enhancing capabilities. For example, hybrid welding, which combines laser and traditional welding techniques, is gaining traction. This method allows for greater versatility in various materials and thicknesses. Moreover, innovations in fiber lasers are making equipment more efficient. These lasers boost speed while reducing energy consumption. Yet, the complexity of integrating these technologies into existing systems raises challenges. Many manufacturers struggle with adaptation.

The rise of automation and AI in laser welding systems is also noteworthy. Automated systems can improve precision and reduce human error. However, there are concerns about job displacement and training needs for workers. As we explore these innovations, the industry must address the balance between advanced technology and workforce development. The path forward is exciting yet fraught with considerations that require careful thought.

The laser welding industry is evolving rapidly. Precision and efficiency drive recent designs. One prominent trend is the integration of automation technologies. Automated laser welding systems are improving production speed by up to 30%. This shift enhances the consistency and quality of welds.

Another trend is the focus on eco-friendly practices. Many manufacturers are adopting energy-efficient components. Reports show that these innovations can reduce energy consumption by over 20%. Companies are keen on minimizing waste generated during welding processes. However, balancing efficiency and sustainability can be challenging.

Ergonomics is also a key factor in machine design. More intuitive interfaces are emerging, allowing operators to work with ease. Interaction between man and machine is crucial for operational success. Yet, the industry still faces hurdles in user training and machine adaptability. Continuous improvement in these areas is essential for future advancements.

Laser welding technology is evolving rapidly, especially in materials and applications. New innovations are making the process more efficient. Advanced materials are now compatible with various welding techniques. Aluminum, for instance, is becoming a preferred choice due to its lightweight and durability. Engineers are discovering ways to enhance their properties. This allows for more versatile applications across industries.

There are also exciting developments in fiber laser technology. These lasers provide greater precision and control. They can weld complex shapes without compromising quality. However, challenges remain. The understanding of laser-material interactions isn't perfect. Some materials still cause difficulties during the welding process. Testing is necessary to avoid issues like distortion or weak bonds.

Application-wise, industries are exploring new frontiers. Automotive, aerospace, and medical sectors benefit greatly from innovations. Yet, there are gaps to fill. Not all applications are compatible with current technology. This calls for ongoing research and adaptation. As these trends unfold, the potential for laser welding appears promising but demanding.

The rise of Industry 4.0 has significantly transformed the laser welding machine landscape. Connectivity and automation are becoming vital. Manufacturers are embracing smart technologies. These advancements allow real-time monitoring of processes. Data analytics offers insights into machine performance. This leads to improved efficiency and reduced downtime. However, many companies still struggle with integration challenges. Managing vast amounts of data can be overwhelming.

As laser welding becomes more advanced, skilled labor is essential. Many operators need more training on new technologies. This gap can hinder productivity, causing delays in production cycles. Furthermore, cybersecurity concerns arise with increased machine connectivity. Protecting sensitive data is crucial, yet often overlooked. The need for robust security measures is evident.

Innovations like adaptive welding systems are exciting but present complexity. These systems dynamically adjust parameters during operation. However, their setup can be intricate and time-consuming. The balance between automation and manual control remains a challenge. Industry 4.0 offers immense potential, but companies must address these concerns to fully realize its benefits.

The development of laser welders is changing rapidly. Environmental considerations are becoming increasingly important. The industry is focusing on reducing their carbon footprint. Innovative technologies aim to enhance energy efficiency. Efficient energy use can lower operational costs significantly.