1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

In today's fast-paced manufacturing landscape, precision and efficiency are paramount, particularly when it comes to branding and marking products. The adoption of advanced technologies has led to significant transformations, and one of the leading innovations in this domain is the laser marking machine for metal. According to a recent report by MarketsandMarkets, the global laser marking industry is projected to reach approximately $5.7 billion by 2025, growing at a compound annual growth rate (CAGR) of 6.4%. This growth is driven by the increasing demand for high-quality markings with improved durability across various industries, including automotive, aerospace, and electronics.

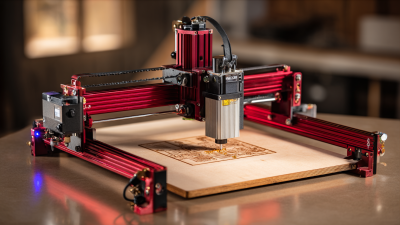

Laser marking machines offer unparalleled advantages over traditional marking methods, such as reduced operational costs, minimal waste, and the ability to produce intricate designs without compromising on speed or quality. Additionally, their versatility allows for marking on a wide range of metal surfaces, making them a preferred choice for manufacturers aiming to enhance product traceability and quality control. As industry standards evolve, understanding the top players in the market and the features of their laser marking machines for metal becomes crucial for businesses seeking to remain competitive.

In this article, we will explore the top 10 laser marking machines for metal that you need to know about, highlighting their specifications, applications, and the unique benefits they bring to modern manufacturing processes.

Laser marking technology has emerged as a crucial process in various metal applications, serving industries from aerospace to automotive. The global market for metal marking and engraving machines is set to grow significantly, reflecting a robust annual growth rate of 10.9%, with projections indicating an increase from $6.85 billion in 2025 to $14.14 billion by 2032. This growth trend underscores the increasing demand for precise and efficient marking solutions as manufacturers seek to improve production quality and traceability.

Different types of laser marking machines cater to specific material compatibilities, including fiber lasers and CO2 lasers, each chosen based on their suitability for a particular application. The versatility of laser marking technology allows for a wide range of uses, such as product identification, branding, and quality control across multiple sectors. As industries continue to adopt advanced manufacturing techniques, innovations in laser marking will play a pivotal role in enhancing operational efficiency and meeting the stringent requirements of modern production environments.

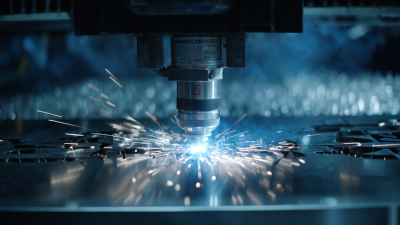

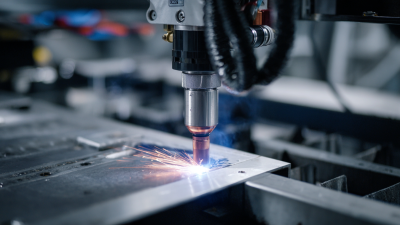

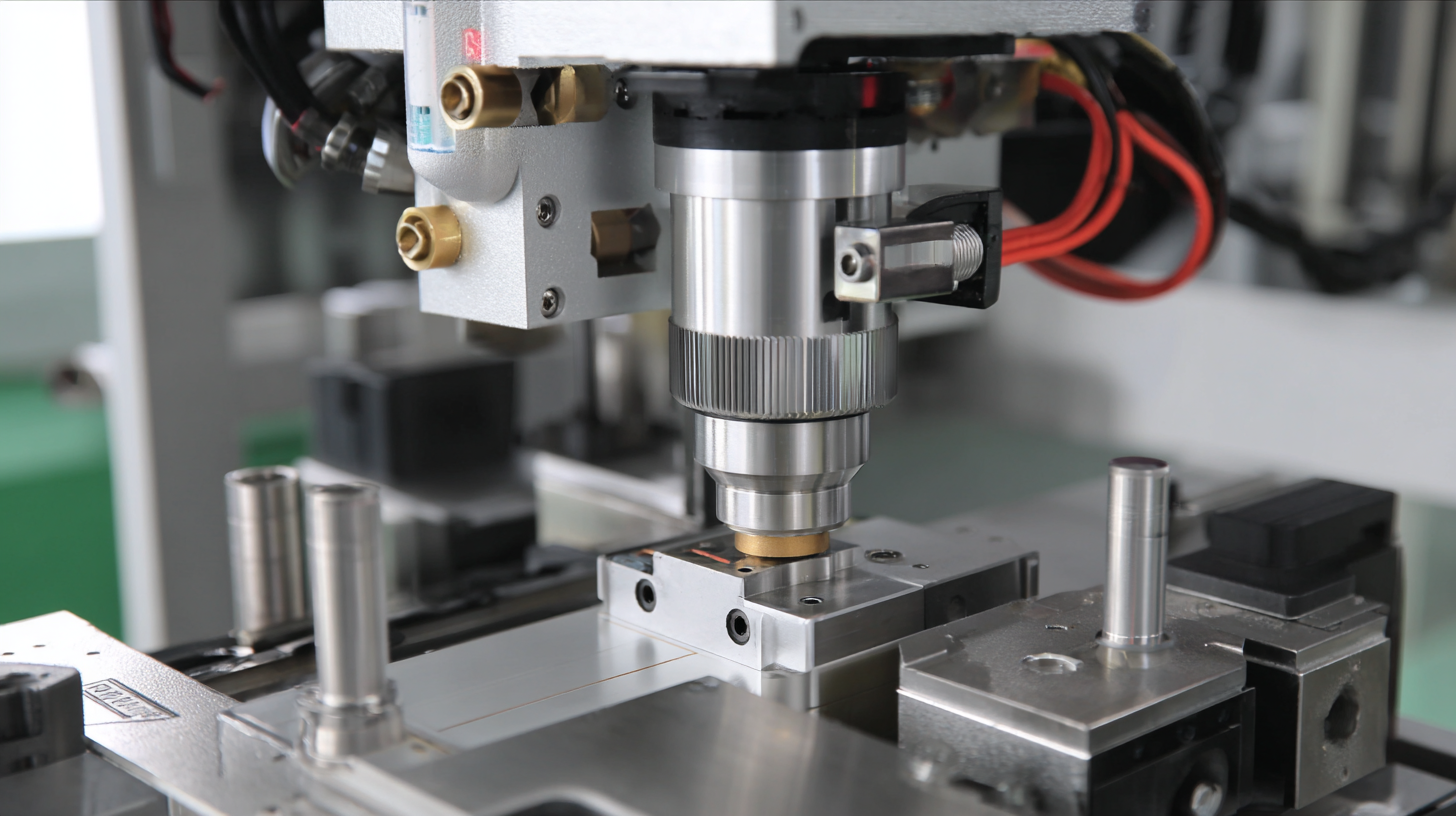

When selecting a metal laser marking machine, several key features should be considered to ensure optimal performance and efficiency. One of the most critical aspects is the type of laser technology used. According to a report from MarketsandMarkets, fiber lasers are currently the preferred choice in the industry due to their high precision and speed compared to traditional CO2 lasers. Fiber lasers have a longer lifespan and require less maintenance, making them a cost-effective option for businesses that rely on marking metal products.

Another important feature to evaluate is the machine’s marking speed and depth capabilities. As highlighted in a study by Research and Markets, faster marking speeds can significantly increase productivity, especially in high-volume production environments. Machines that offer adjustable marking depth allow for versatility in applications ranging from simple logos to intricate designs, making them suitable for various metal types. Additionally, software compatibility is crucial; user-friendly interfaces and robust design programs can enhance the overall experience and facilitate more complex designs, ultimately improving the quality of the markings.

Laser marking has become an essential technology in the metalworking industry, offering precision and efficiency for various applications. According to a report by Market Research Future, the global laser marking machine market is expected to grow at a CAGR of 5.7% from 2020 to 2026, driven by the increasing demand for high-accuracy marking solutions. Among the numerous options available, five machines stand out for their exceptional capabilities in precision metal marking.

The global industrial lasers market is poised for significant growth, with projections indicating an increase from

$23.90 billion in 2025 to

$55.09 billion by 2032, reflecting a remarkable

CAGR of 12.7%. This surge can be attributed to the expanding applications of

laser technology across various industries, including manufacturing and metal processing. Among these technologies,

laser marking machines have emerged as essential tools for providing

precise and permanent markings on metal surfaces, paving the way for advancements in product identification, traceability,

and aesthetics.

In parallel, the laser engraving machine market is also witnessing robust expansion, with an anticipated growth from

$3.27 billion in 2024 to

$5.84 billion by 2032, translating to a

CAGR of 8.2%. This growth is driven by increasing demand for

high-quality engraving solutions that facilitate intricate designs and personalization across metal products. As industries

increasingly recognize the advantages of incorporating laser technology, the comparative analysis of leading solutions in

the metal laser marking segment becomes critical for businesses looking to invest in effective marking solutions that

enhance productivity and differentiate their products in competitive markets.

When it comes to laser marking machines for metal, user feedback is crucial in guiding potential buyers. According to a report by MarketsandMarkets, the laser marking industry is expected to reach USD 6.5 billion by 2027, highlighting the increasing demand for advanced marking solutions. Users frequently emphasize the importance of precision and reliability, with reviews noting that machines like the Epilog Fusion Pro deliver exceptional engraving quality thanks to their superior optical systems.

Moreover, concerns over maintenance and operational costs also feature prominently in user discussions. A survey presented in the Laser Association's annual report indicated that 68% of respondents prefer machines that offer low upkeep without compromising performance. For instance, the Universal Laser Systems' PLS6.75 machine receives praise for its minimal maintenance needs while still producing high-resolution marking on various metals, such as stainless steel and aluminum. These insights underline the importance of selecting a laser marking machine that not only meets technical specifications but also aligns with user experiences and preferences in real-world applications.