1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

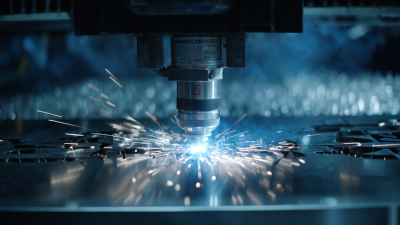

In the realm of precision engineering, the significance of laser machines has surged dramatically over the past few years. According to a recent market analysis by TechNavio, the global laser cutting machine market was valued at approximately $3.4 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.9% through 2027. This growth is attributed to the ongoing advancements in laser technology and the rising demand for precision fabrication across various sectors, including automotive, aerospace, and electronics.

Industry expert Dr. Alice Thompson, a renowned authority in laser technologies, emphasizes the critical role of these machines in revolutionizing manufacturing processes. She states, "Laser machines not only enhance precision but also contribute to significant efficiency gains, enabling manufacturers to meet the growing demands for quality and speed in production." As we explore the top 10 laser machines for precision engineering in 2023, it becomes evident that these innovations are setting new standards in accuracy, flexibility, and operational effectiveness, making them indispensable tools in modern manufacturing landscapes. In a world where precision is paramount, the evolution of laser machines continues to shape the future of engineering and fabrication.

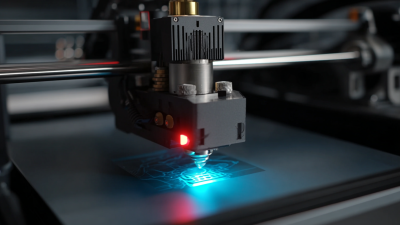

Laser technology has revolutionized precision engineering, offering unparalleled accuracy and efficiency in various manufacturing processes. According to the International Federation of Robotics, the integration of laser systems in industrial applications has seen exponential growth, with a projected increase of 25% in laser machine adoption over the next three years. This surge is driven by the need for high precision in cutting, engraving, and welding processes, which are essential across multiple industries including aerospace, automotive, and electronics.

The application of laser technology enables engineers to achieve intricate designs and tight tolerances that traditional machining methods struggle to match. The use of fiber lasers, for instance, has become particularly prominent due to their high beam quality and operational efficiency. A report from Research and Markets indicates that the global laser cutting market is expected to reach $6.8 billion by 2026, highlighting the growing demand for precision laser applications. Furthermore, the ability of laser systems to automate processes contributes to significant cost savings and productivity enhancements, allowing manufacturers to meet the increasing demands of customized production and fast turnaround times.

As precision engineering continues to evolve, laser technology remains at the forefront, facilitating advancements in design capabilities and operational efficiency, while driving the industry towards greater automation and innovation.

| Laser Machine Model | Power Output (W) | Cutting Thickness (mm) | Max Speed (m/min) | Application |

|---|---|---|---|---|

| Laser Pro 1000 | 1000 | 10 | 30 | Metal Cutting |

| Laser Max 1500 | 1500 | 15 | 35 | Sheet Metal |

| Laser Expert 2000 | 2000 | 20 | 40 | Precision Cutting |

| Laser Ultra 3000 | 3000 | 25 | 50 | Industrial Applications |

| Laser Precision 3500 | 3500 | 30 | 60 | Automotive Parts |

| Laser Mega 4000 | 4000 | 35 | 55 | Prototyping |

| Laser Fusion 5000 | 5000 | 40 | 70 | Fabrication |

| Laser Titan 6000 | 6000 | 45 | 80 | Aerospace Components |

| Laser Vision 7000 | 7000 | 50 | 90 | Medical Devices |

| Laser Quantum 8000 | 8000 | 55 | 100 | High-Volume Production |

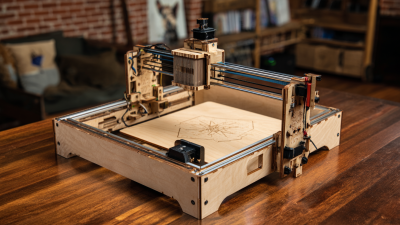

When selecting laser machines for precision engineering, there are several key features to consider that can significantly impact performance and efficiency. First and foremost, the power of the laser is crucial, as it determines the machine's ability to cut through various materials. Higher wattage often translates to faster cutting speeds and the ability to work with thicker materials. Additionally, the type of laser technology—whether CO2, fiber, or diode—plays an essential role in the suitability of the machine for specific applications, as each type has distinct advantages and limitations in terms of materials and precision.

Another critical aspect to evaluate is the engraving and cutting area size. A larger work area allows for more flexibility in processing bigger materials, which is particularly advantageous for comprehensive projects. Furthermore, consider the machine's accuracy and repeatability, which are vital for tasks requiring high precision. Advanced features like automated focus adjustment and integrated software for design manipulation can also enhance user experience and output quality. Finally, the machine's build quality and durability are important for long-term investment, ensuring that it withstands the rigors of frequent usage while maintaining consistent performance.

The landscape for laser machines in precision engineering is continually evolving, with various manufacturers leading the way in technological advancements. In 2023, the demand for high-performance laser systems is being driven by sectors such as aerospace, automotive, and electronics, where precision is non-negotiable. Recent industry reports indicate that the global laser machine market is projected to reach $9 billion by 2025, reflecting a compound annual growth rate (CAGR) of approximately 6% from 2021 to 2025. This growth is attributed to the increasing adoption of laser technology for cutting, engraving, and industrial machining.

When considering manufacturers of laser machines for precision engineering, it's crucial to evaluate their innovation capabilities, after-sales support, and integration with automation systems. Leading manufacturers are focusing on enhancing the efficiency and accuracy of their laser systems, often incorporating advanced technologies such as artificial intelligence and machine learning to optimize processes. According to a survey by the International Laser Manufacturing Society, over 70% of industry professionals emphasize that investing in reputable manufacturers directly correlates with operational excellence and improved productivity.

Tip: When selecting a laser machine, consider not only the initial costs but also the long-term operational expenses and support service availability. Ensuring that you have access to technical assistance and parts can significantly affect your overall productivity.

Tip: Stay updated with the latest advancements in laser technology through industry webinars and publications. This knowledge will help you make informed decisions and maintain a competitive edge in precision engineering.

In 2023, precision engineering has seen significant advancements in laser machine technology, with a variety of models providing enhanced capabilities for manufacturing applications. A comparative analysis of the top 10 laser machines reveals that features such as beam quality, cutting speed, and operational efficiency are crucial in determining their performance. According to a recent report by the International Federation for Automation and Robotics (IFAR), laser-cutting technology accounts for approximately 30% of the global market share within precision engineering, underlining its importance in modern fabrication processes.

In examining these machines, key specifications such as wattage, cutting thickness, and control systems are compared to assess their suitability for different applications. For instance, machines with higher wattage have been shown to improve cutting speeds by up to 20%, which is critical in high-demand production environments. Additionally, advancements in closed-loop control systems have enhanced accuracy and repeatability, as reported in the 2023 Precision Engineering Market Analysis. This trend indicates a shift toward automated solutions, which not only increase efficiency but also reduce operational costs significantly. Companies investing in such laser technologies are likely to see substantial improvements in their production capabilities and overall competitiveness in the industry.

The future of laser technology in precision engineering is set to be transformative, driven by advancements in efficiency and capability. According to a recent report by MarketsandMarkets, the global laser technology market is projected to reach $16.2 billion by 2025, growing at a CAGR of approximately 7.5%. This growth is fueled by increasing demand across various industries, including aerospace, automotive, and electronics, where precision is paramount. The integration of AI and machine learning into laser processes is a significant trend, enabling real-time adjustments and enhancing accuracy during manufacturing.

Moreover, the emergence of ultrafast lasers, which can deliver extremely short bursts of energy, is revolutionizing the precision engineering landscape. These lasers are particularly beneficial for micromachining applications, allowing for the creation of intricate designs with minimal thermal damage to the material. A study published in the Journal of Laser Applications highlights that ultrafast laser processing can achieve tolerances in the micrometer range, making it ideal for sectors requiring high precision, such as medical device manufacturing and semiconductor production.

As laser technology continues to evolve, we can expect an increase in hybrid systems that combine traditional manufacturing methods with advanced laser techniques. This integration not only enhances production speed and flexibility but also leads to improved sustainability by reducing material waste. As reported by Grand View Research, the global market for hybrid manufacturing technologies is anticipated to exhibit robust growth, underscoring the pivotal role lasers will play in shaping the future of precision engineering.