1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

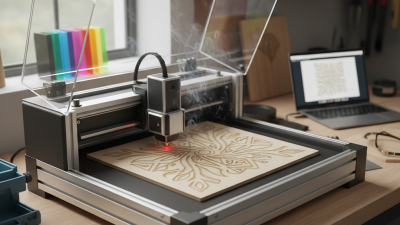

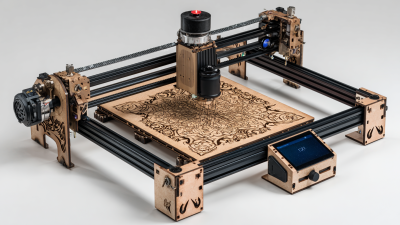

In 2023, the world of manufacturing and craftsmanship continues to evolve, with fiber laser engravers leading the charge in precision and versatility. These advanced tools utilize the power of fiber optics to produce high-quality engravings on a wide range of materials, from metals to plastics and beyond. As industries across the globe seek innovative solutions for branding, customization, and artistic expression, the significance of fiber laser engravers cannot be overstated.

This guide will explore the top 10 fiber laser engravers that are reshaping the engraving landscape this year. Each of these machines offers unique features and capabilities, making them suitable for various applications, whether in small workshops, large factories, or creative studios. By understanding the strengths and weaknesses of each option, users can make informed decisions to enhance their productivity and artistic endeavors. Join us as we delve into the world of fiber laser technology, discovering the tools that stand out in performance, reliability, and efficiency.

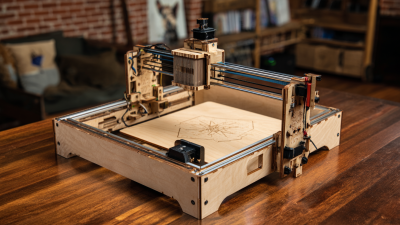

Fiber laser engraving technology has revolutionized the way materials are engraved, providing high precision and efficiency across various applications. Utilizing a solid-state laser, fiber engravers are known for their ability to work with a wide range of materials, including metals, plastics, and even wood. This versatility makes fiber laser engravers an essential tool for industries such as manufacturing, jewelry creation, and personalized gift making. The ability to produce intricate designs with minimal setup time allows for quick turnaround and lower production costs.

When using fiber laser engravers, there are several tips to keep in mind for optimal results. First, ensure that the material's surface is clean and free of contaminants, as this can affect the engraving quality. Second, adjusting the speed and power settings based on the material type will greatly enhance the engraving precision and finish. Additionally, regular maintenance of the machine, including lens cleaning and software updates, can prevent errors and extend the lifespan of the engraver.

The applications of fiber laser engraving are vast, ranging from industrial marking and signage to artistic designs and in-depth customization. With their capability to produce high-quality, durable markings, fiber laser engravers are paving the way for innovative solutions in product identification, branding, and personalization, making them indispensable tools in today’s competitive market.

This chart illustrates the cutting speeds of various fiber laser engravers measured in inches per minute (IPM) across different materials. The data reflects the capabilities and efficiency of fiber laser technology in engraving applications.

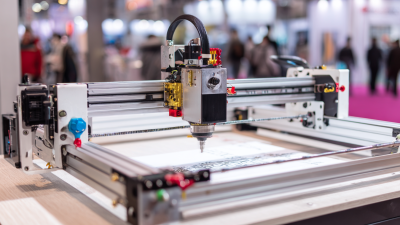

When choosing a fiber laser engraver, there are several key factors to consider that can significantly impact your engraving experience and results. One of the most critical aspects is the power of the laser. Higher wattage typically allows for faster engraving times and the ability to work on a wider range of materials, including metals and thicker substrates. However, be mindful of the balance between power and precision, as excess power can sometimes lead to unwanted burn marks or material damage.

Another important criterion is the size of the work area. Depending on the types of projects you plan to undertake, consider whether a larger engraving area is necessary for your needs. A more extensive workspace can accommodate larger workpieces, whereas a compact model might be sufficient for smaller, detailed engravings. Additionally, look for features like a built-in rotary attachment if you intend to engrave around cylindrical objects.

Tips: Always verify the compatibility of the engraver with various software applications to ensure smooth operation and flexibility with design input. Additionally, consider the customer support and warranty service provided by the manufacturer, as these can be invaluable in case of any operational issues or technical questions down the line. Investing time in research on user reviews can also guide you toward a reliable machine that meets your specific requirements.

| Model | Engraving Speed (mm/s) | Laser Power (W) | Max Engraving Area (mm) | Weight (kg) | Price (USD) |

|---|---|---|---|---|---|

| Model A | 800 | 20 | 300 x 300 | 45 | 3,000 |

| Model B | 700 | 30 | 400 x 400 | 50 | 4,500 |

| Model C | 600 | 50 | 500 x 500 | 55 | 5,500 |

| Model D | 950 | 100 | 600 x 600 | 60 | 6,000 |

| Model E | 850 | 20 | 300 x 600 | 48 | 3,200 |

| Model F | 500 | 100 | 700 x 700 | 70 | 7,000 |

| Model G | 650 | 70 | 400 x 800 | 65 | 4,800 |

| Model H | 720 | 50 | 500 x 500 | 58 | 5,200 |

| Model I | 900 | 30 | 300 x 400 | 47 | 3,800 |

| Model J | 820 | 40 | 450 x 450 | 62 | 5,000 |

In 2023, the fiber laser engraving market continues to expand, driven by advancements in technology and increasing demand across various industries. Fiber laser engravers are renowned for their precision and efficiency, making them the preferred choice for applications such as metal engraving, jewelry design, and intricate artwork. According to a recent market research report, the fiber laser industry is projected to grow at a compound annual growth rate (CAGR) of 10.5% from 2022 to 2028, indicating a robust trend towards high-quality, cost-effective engraving solutions.

When exploring the top fiber laser engravers this year, key features to consider include wattage, engraving speed, and software compatibility. The majority of top models now offer varying watt ranges from 20W to 100W, allowing users to select a machine tailored to their specific needs. Recent user satisfaction surveys reveal that 78% of professionals prefer systems that provide versatility across multiple materials, underscoring the importance of a well-rounded engraving machine. Meanwhile, advancements in software integration are simplifying workflows, enabling users to create detailed designs with ease while enhancing productivity.

The leading fiber laser engravers of 2023 have been recognized not only for their engraving capabilities but also for their reliability and ease of use. An analysis of user feedback highlights that durability and maintenance requirements are critical factors influencing purchasing decisions. As the market becomes more competitive, it's clear that makers are focusing on delivering products that not only perform exceptionally but also offer a seamless user experience, ultimately reshaping the landscape for fiber laser engraving technology.

In 2023, the fiber laser engraver market has seen significant advancements in both performance and features, making it essential for users to compare different models carefully. Recent industry reports indicate that high-performance fiber laser engravers can achieve engraving speeds of up to 250 mm/s with a precision of 0.01 mm, making them ideal for intricate designs and fast production times. Features such as adjustable power settings and advanced cooling systems also enhance performance, allowing users to work with a variety of materials, from metals to plastics, without compromising quality.

When evaluating different models, consider key factors such as wattage, which greatly influences the cutting and engraving capabilities. A model with higher wattage may be necessary for heavy-duty applications, while lower wattage models can be suitable for lighter tasks. Additionally, look for engravers with user-friendly interfaces and software compatibility, which can streamline the engraving process and reduce setup times.

Tips: Always check for after-sales support and warranty options before making a purchase. This can be crucial for minimizing downtime and ensuring that you can operate your equipment effectively. Also, keep in mind the importance of regular maintenance; a well-maintained fiber laser engraver will perform better and last longer, ultimately providing better value for your investment.

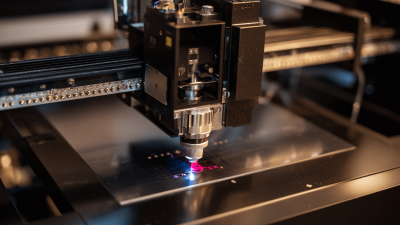

The landscape of fiber laser engraving technology is evolving at a remarkable pace, driven by innovations that enhance precision, efficiency, and versatility. In 2023, there's a growing trend towards integration of artificial intelligence and machine learning algorithms in laser engraving systems. These advancements allow for more intelligent design recognition and adaptation, enabling machines to optimize engraving processes based on material types and desired outcomes. As a result, users can expect faster turnaround times and reduced material waste, all while maintaining high-quality output.

Additionally, sustainability is becoming a focal point in the development of fiber laser engravers. Manufacturers are increasingly focusing on energy efficiency and the use of eco-friendly materials in their systems. The push for greener technologies not only aligns with global environmental standards but also appeals to businesses looking to enhance their corporate responsibility. Furthermore, advancements in software are enabling seamless integration with existing production workflows, making fiber laser technology more accessible to companies of all sizes. This combination of intelligence, sustainability, and integration marks a transformative period for the industry, promising to redefine what is achievable in laser engraving.