1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

In recent years, the industrial landscape has seen a significant transformation driven by advancements in technology, particularly with the introduction of the fiber laser engraving machine. According to a report by MarketsandMarkets, the global laser engraving market is expected to reach $5.02 billion by 2025, growing at a CAGR of 5.9% during the forecast period. This growth is largely attributed to the precision and efficiency that fiber laser engraving machines offer across various applications, from automotive to aerospace and beyond. By harnessing high-powered fiber lasers, manufacturers can achieve intricate designs with remarkable speed and accuracy, thus reducing waste and operational costs.

As industries increasingly seek to adopt these innovative solutions, understanding the capabilities and applications of fiber laser engraving is essential for staying competitive in today’s market.

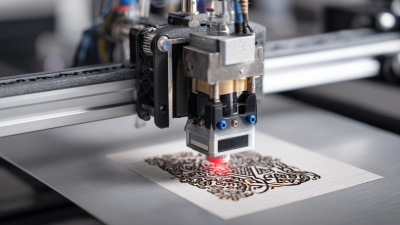

Fiber laser engraving machines are ushering in a new era of precision in industrial applications. With advancements in technology, these machines offer unparalleled accuracy and efficiency, allowing manufacturers to achieve intricate designs and detailed markings on various materials. This increased precision not only enhances the quality of products but also streamlines production processes, reducing waste and operational costs.

Fiber laser engraving machines are ushering in a new era of precision in industrial applications. With advancements in technology, these machines offer unparalleled accuracy and efficiency, allowing manufacturers to achieve intricate designs and detailed markings on various materials. This increased precision not only enhances the quality of products but also streamlines production processes, reducing waste and operational costs.

The fiber laser market is experiencing significant growth, driven by the rising demand for advanced manufacturing solutions across various industries. However, challenges such as the need for continual innovation and the integration of new technologies remain. Companies are now focused on developing high-powered fiber lasers, such as the recent introduction of a 30 kW model, which redefines capabilities in metal cutting. As the industry evolves, the ongoing competition among manufacturers fuels further advancements, ensuring that fiber laser engraving machines continue to set new standards in industrial precision.

Fiber laser engraving technology has revolutionized industrial applications by offering unmatched precision and efficiency. According to a report from MarketsandMarkets, the global fiber laser market is projected to reach $4.75 billion by 2026, growing at a CAGR of 8.5%. This growth is driven by the technology's ability to produce intricate designs with minimal material waste, making it an attractive choice for manufacturers looking to optimize their production processes.

One of the key features of fiber laser engraving machines is their high-speed processing capability. These machines can engrave up to 100 times faster than traditional engraving methods, significantly reducing production times. Additionally, fiber lasers operate without the need for additional gases or chemicals, which not only decreases operational costs but also minimizes environmental impact. A study published by the Laser Institute of America highlights that these machines maintain precision over longer periods, ensuring consistent output quality essential for industries such as automotive and aerospace, where tolerances are critical.

Moreover, fiber laser technology offers versatility in working with a wide range of materials, including metals, plastics, and ceramics. This adaptability is evidenced by a report from Laser Focus World, which states that fiber lasers can effectively engrave complex designs on various surfaces, appealing to diverse sectors like electronics and jewelry. With such advantages, fiber laser engraving machines are set to become a cornerstone of efficiency and precision in industrial applications.

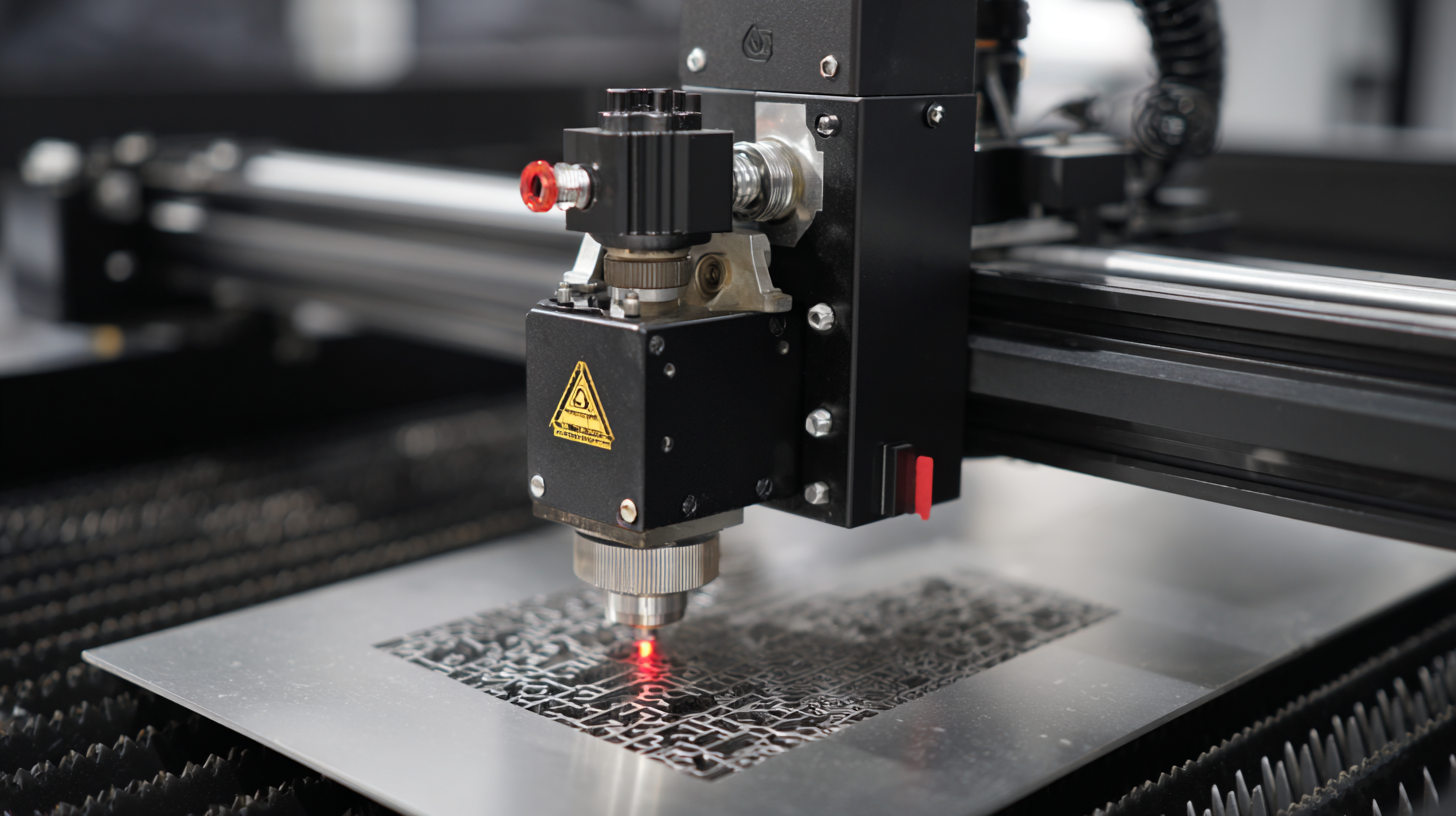

Fiber laser engraving machines have revolutionized various industries, providing unparalleled precision and efficiency in marking, cutting, and engraving materials. According to a report by MarketsandMarkets, the global fiber laser market is projected to reach approximately $4.49 billion by 2025, growing at a CAGR of 10.5%. This surge is driven by the increasing adoption of fiber lasers in industries such as automotive, electronics, and aerospace, where accuracy is paramount. For instance, in the automotive sector, fiber lasers are utilized for engraving VIN numbers and logos, enhancing security and traceability.

In the electronics industry, fiber laser engraving is employed for micro-marking on circuit boards and components, facilitating high-density information storage and easy identification. A recent study from ResearchAndMarkets highlights that the electronics segment is forecasted to capture a significant share of the fiber laser market, due to the rising demand for miniaturization and rapid production processes. Additionally, in the aerospace industry, the precision offered by fiber lasers ensures that critical components can be marked without compromising their structural integrity, leading to enhanced safety and reliability in flight operations.

The versatility and effectiveness of fiber laser engraving machines make them indispensable in modern industrial applications, driving innovation and improving productivity across sectors.

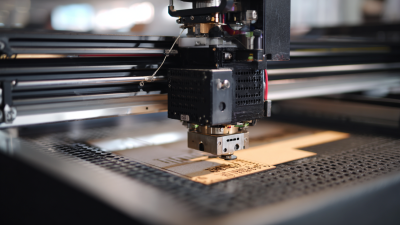

Fiber laser engraving machines have emerged as a revolutionary alternative to traditional engraving methods, showcasing several comparative advantages. Unlike conventional techniques such as rotary screen printing, which can be time-consuming and labor-intensive, fiber laser engraving offers unmatched precision and speed. This advanced technology enables intricate designs and high-resolution engravings without the extensive setup and material waste often associated with traditional methods, making it a more sustainable option for industrial applications.

Furthermore, fiber lasers outperform traditional engraving methods in terms of versatility and adaptability. While conventional processes may require different tools for various materials, fiber lasers can efficiently engrave a wide range of substrates, from metals to plastics, with minimal adjustments. The efficiency gained through automation and programmable settings further enhances productivity, allowing manufacturers to meet the demands of dynamic markets more effectively. Overall, the adoption of fiber laser engraving represents a significant advancement in achieving precise and efficient production capabilities across industries.

This chart illustrates the comparative advantages of fiber laser engraving machines over traditional engraving methods across various dimensions such as precision, speed, material versatility, operating cost, and maintenance requirements. The data shows that fiber laser engraving significantly outperforms traditional methods in precision, speed, and material versatility while having higher operating costs but comparable maintenance needs.

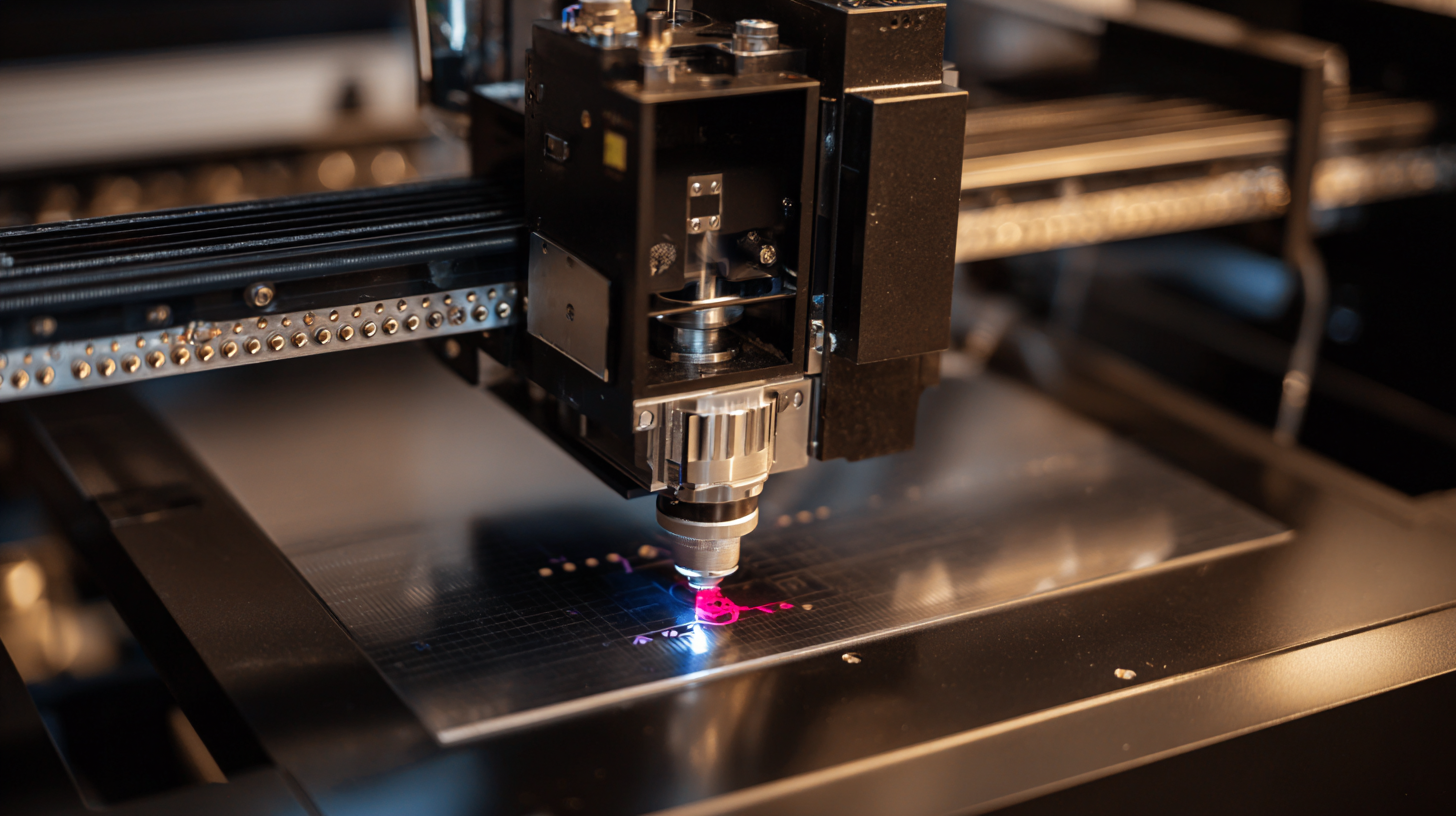

The future of fiber laser technology is poised to revolutionize industrial applications, profoundly impacting efficiency and precision. As industries continue to demand higher productivity and accuracy, advancements in fiber laser engraving machines are becoming increasingly crucial. Enhanced beam quality and improved power output allow these systems to operate at unprecedented speeds, making them ideal for a range of materials, from metals to polymers. This adaptability not only streamlines manufacturing processes but also reduces waste, leading to more sustainable production methods.

In addition to performance improvements, emerging trends indicate that fiber laser technology will integrate more seamlessly with automation and artificial intelligence. Smart manufacturing systems that utilize real-time data analytics will optimize engraving processes, ensuring consistency and reducing errors. The incorporation of IoT-enabled devices will further enable manufacturers to monitor equipment performance and predictive maintenance, significantly minimizing downtime. As industries adopt these innovations, the long-term impact on productivity, cost-efficiency, and product quality will mark a significant shift in how laser engraving is approached in the industrial sector.

| Application Area | Precision Level (µm) | Engraving Speed (m/min) | Material Compatibility | Energy Efficiency (%) |

|---|---|---|---|---|

| Aerospace Components | 25 | 15 | Aluminum, Titanium | 85 |

| Automotive Parts | 30 | 20 | Steel, Plastic | 80 |

| Medical Devices | 15 | 10 | Titanium, Biocompatible Plastics | 90 |

| Electronics | 10 | 25 | Copper, PCB materials | 88 |

| Jewelry | 5 | 5 | Gold, Silver | 75 |