1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

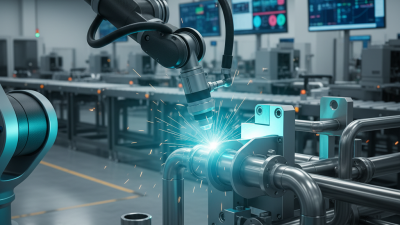

The manufacturing industry is undergoing a transformation with advanced welding techniques. One of these techniques is using a laser welding gun, which has become a preferred choice for many applications. According to a recent report by the International Institute of Welding, laser welding can achieve up to 50% higher efficiency compared to traditional methods. This improvement can significantly reduce production costs and lead times.

Experts emphasize the importance of proper technique when using a laser welding gun. Dr. Emily Carter, a renowned welding specialist, states, "The precision of a laser welding gun can revolutionize metal joining if used correctly." Despite its advantages, many users still struggle with the equipment. Improper settings can lead to defects such as burn-through or inadequate fusion.

In professional settings, it's crucial to evaluate the equipment frequently. A laser welding gun requires regular maintenance to ensure optimal performance. Users often overlook this aspect. The implications of neglect can result in costly errors and wasted materials. Continuous training is essential for maximizing the benefits of laser welding technology in today’s competitive industry.

Laser welding technology is revolutionizing metal joining techniques. It provides precision and efficiency. The process uses concentrated beams of light to melt metal surfaces. This results in strong welds with minimal thermal distortion. Industries like automotive, aerospace, and electronics benefit from this technology. Applications vary from fabrication to repair.

Tips for users: Always ensure proper safety gear. Protective glasses are essential to shield against laser exposure. Additionally, maintain a clean workspace to enhance weld quality. Dust and debris can lead to imperfections. Remember, even experienced operators make mistakes. Regular practice is key to achieving consistent results.

Understanding the nuances of laser welding is vital. Remember that each metal type has specific settings. This can complicate the process. Monitoring parameters like speed and power is crucial. Even slight adjustments can impact the outcome. Be prepared for trial and error. This technology may seem straightforward, but mastery requires time and patience.

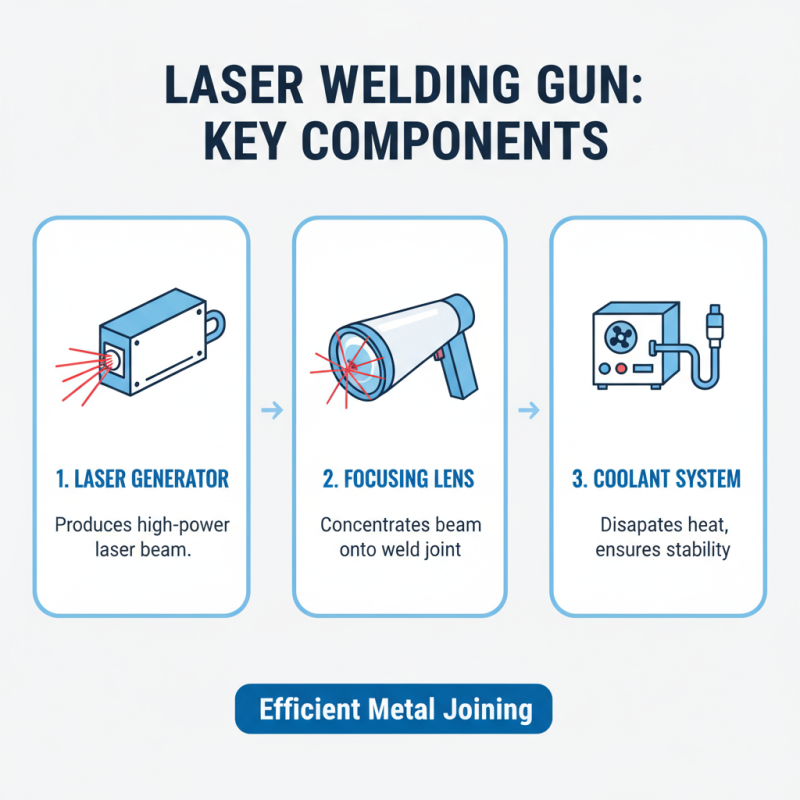

A laser welding gun is a powerful tool for joining metals. Understanding its essential components can help you use it more effectively. The key parts include the laser generator, focusing lens, and coolant system. Each component plays a specific role in the welding process.

The laser generator produces focused light, creating heat to melt the metal. This is where precision is crucial. Focus too much energy in one spot and the metal can warp. The focusing lens directs the beam. If misaligned, it can lead to inconsistent welds. Lastly, the coolant system ensures the gun doesn’t overheat. If it fails, the gun’s performance is compromised, resulting in poor welds.

Wielding this tool requires practice. New users often face challenges. Finding the right settings can be time-consuming. Even an expert can struggle with different metals. Continuous learning and adjustments are part of mastering this technique. Each project teaches something new, highlighting the importance of experience in achieving efficient metal joining.

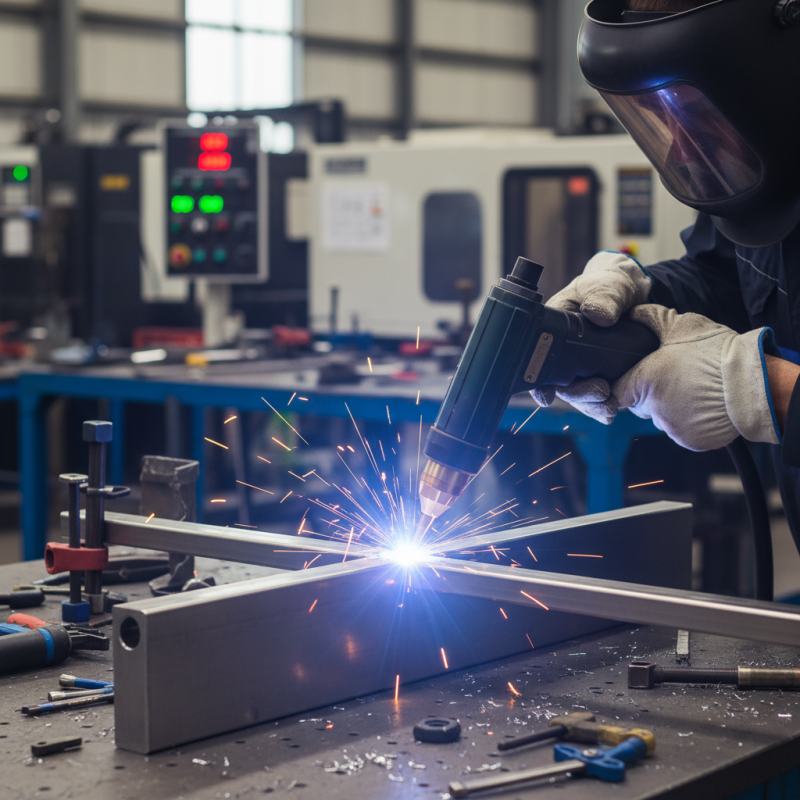

Operating a laser welding gun requires precision and care. Begin by setting up a stable work surface. Ensure all materials to be joined are clean and properly aligned. A clean workspace minimizes contamination. Secure the pieces using clamps if needed, to avoid movement during the process. Adjust the focal length based on material thickness, as this affects the weld quality.

Next, wear appropriate safety gear. This includes goggles to protect your eyes from harmful beams. Turn on the welding gun and select the right power settings. Aiming the laser beam correctly is crucial. Hold the gun steady, and move it at a consistent speed. If you notice any inconsistent welds, pause to reassess your technique. Uneven pressure or speed can lead to weak joints.

After welding, inspect the joint for flaws. Look for cracks or incomplete sections. If necessary, rework areas that need improvement. Remember, practice makes perfect, but reflection is key. Each weld can teach something new. Embrace mistakes for growth.

Laser welding offers precise metal joining techniques, but it comes with challenges.

Heat management is one of the main issues.

Excessive heat can distort metal parts. This can lead to poor joints or weakened structures.

Keeping a close eye on heat input is essential.

It requires practice and adjustment.

Another challenge is material compatibility.

Different metals behave differently under a laser. Proper fit-up is crucial. A gap can lead to improper weld penetration.

Ensure that surfaces are clean and free from contaminants. Each material may require unique parameters for successful welding.

Tips:

1. Familiarize yourself with different metals. Adjust settings based on their properties.

2. Perform test welds before starting a new project. This builds confidence and improves quality.

3. Keep a journal of your experiences. Note what works and what doesn’t. Reflect on each project to enhance your skills.

Overcoming these challenges demands patience. Metal joints may not always meet expectations on the first try. Revisiting your approach leads to improvement.

Remember, learning is part of the process in mastering laser welding.

Laser welding is an advanced technique for metal joining, but it comes with strict safety requirements. According to industry reports, around 30% of laser welding incidents arise from inadequate safety practices. Operators must wear appropriate protective gear, such as goggles, gloves, and aprons. Neglecting safety equipment increases the risk of serious injuries.

Proper training is essential. Employees should be familiar with laser hazards and emergency protocols. Regular safety audits can mitigate risks effectively. A study from the Welding Institute indicates that well-trained workers are 50% less likely to be involved in accidents. It's crucial to maintain a clean work environment to avoid fire hazards.

**Tip:** Always keep a fire extinguisher nearby during laser welding operations.

Monitoring exposure to laser radiation is vital. Use of warning signs and barriers can prevent unauthorized access to the welding area. Even small lapses, like not using shields, can lead to severe accidents. Maintaining equipment in top condition is another aspect often overlooked.

**Tip:** Schedule regular maintenance checks to avoid equipment failures.

Incorporating these safety standards and best practices can help ensure that laser welding processes are not only efficient but also safe for all involved.

| Technique | Material Type | Power Output (W) | Join Type | Safety Standard |

|---|---|---|---|---|

| Spot Welding | Steel | 1000 | Single spot | ISO 3834 |

| Butt Welding | Aluminum | 1200 | Continuous seam | EN 15085 |

| Seam Welding | Stainless Steel | 1500 | Linear joint | ASTM E292 |

| TIG Welding | Carbon Steel | 2000 | Fillet weld | ANSI Z49.1 |

| Laser Hybrid Welding | Copper | 1800 | Combined process | ISO 9013 |

| Laser Beam Welding | Nickel Alloys | 2500 | Deep penetration | ISO 14732 |