1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

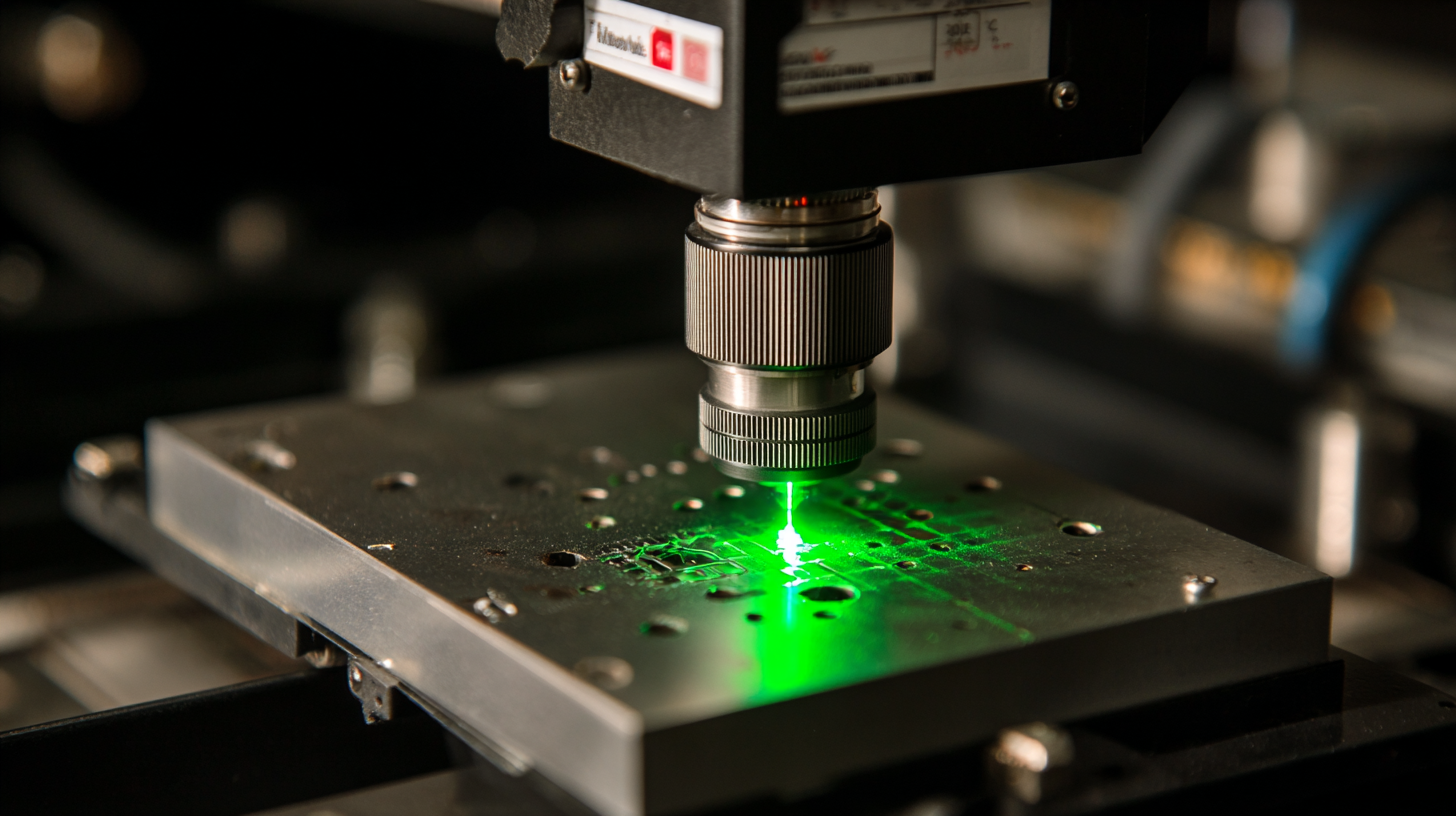

Laser marking technology has emerged as a pivotal advancement in various industries, offering precise and permanent marking solutions for a wide array of materials.

According to a recent report from Global Market Insights, the laser marking market is projected to exceed $7 billion by 2026, driven by the growing demand for customization and traceability in products.

This technology utilizes focused laser beams to engrave or etch designs, barcodes, and logos onto surfaces with remarkable accuracy and speed.

The appeal of laser marking lies in its versatility, as it can be applied to metal, plastic, glass, and more, serving sectors ranging from automotive to electronics.

As industries increasingly prioritize efficiency and quality, understanding the fundamentals of laser marking is essential for harnessing its full potential in manufacturing processes.

Laser marking technology has emerged as a pivotal advancement in various industries, offering precise and permanent marking solutions for a wide array of materials.

According to a recent report from Global Market Insights, the laser marking market is projected to exceed $7 billion by 2026, driven by the growing demand for customization and traceability in products.

This technology utilizes focused laser beams to engrave or etch designs, barcodes, and logos onto surfaces with remarkable accuracy and speed.

The appeal of laser marking lies in its versatility, as it can be applied to metal, plastic, glass, and more, serving sectors ranging from automotive to electronics.

As industries increasingly prioritize efficiency and quality, understanding the fundamentals of laser marking is essential for harnessing its full potential in manufacturing processes.

Laser marking technology is a precise and efficient method used to create markings on various materials through the application of focused laser beams. This process involves using a high-energy laser to remove material from the surface, alter its properties, or engrave designs, making it an ideal choice for applications in industries like manufacturing, aerospace, and healthcare. The technology can be applied to metals, plastics, ceramics, and more, enabling versatility in production and customization processes.

Understanding the basics of how laser marking works involves recognizing the different types of lasers used, such as fiber, CO2, and solid-state lasers. Each type has unique characteristics that influence its application and effectiveness on specific materials. The laser's energy is directed onto the surface of the object, where it interacts with the material to produce permanent markings. These markings can range from simple text and logos to intricate designs and codes, ensuring durability and high visibility for identification or branding purposes. Overall, laser marking technology stands out for its speed, accuracy, and ability to produce high-quality results with minimal impact on the material's integrity.

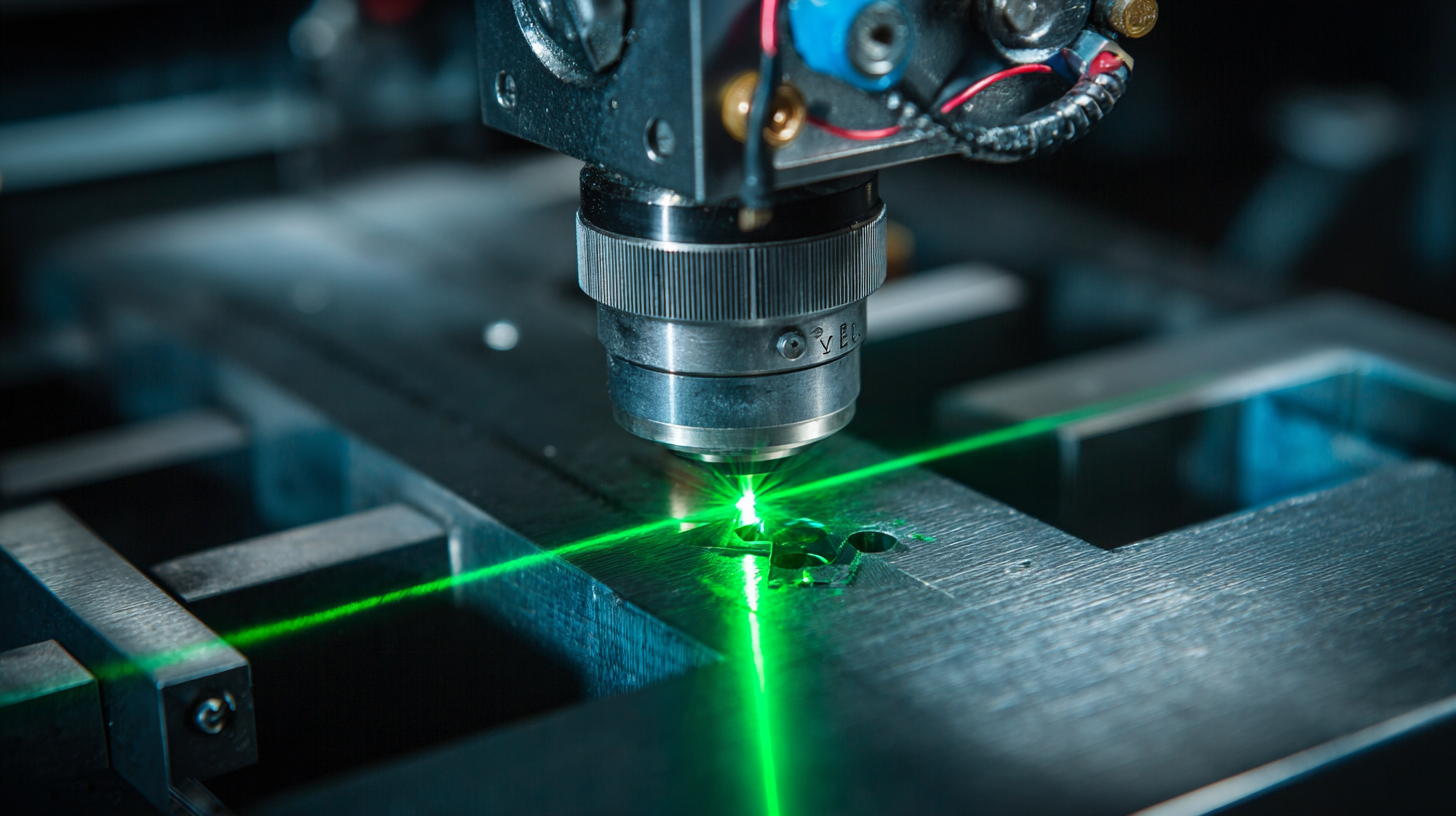

Laser marking technology has gained significant traction in various industries due to its precision and effectiveness. The key components and equipment involved in this process include laser sources, marking heads, and control systems. Laser sources, such as fiber, CO2, or solid-state lasers, generate the light necessary for marking. According to a recent market analysis, the fiber laser segment is expected to grow at a CAGR of 7.5% over the next five years, driven by its efficiency and versatility in marking metals and plastics.

Marking heads are crucial as they define the area and quality of the mark. These heads use a series of lenses and mirrors to focus the laser beam for precise applications. Additionally, advanced control systems allow for the customization of marking parameters, enabling businesses to meet specific production requirements. Reports predict that the integration of smart technologies into these systems will improve productivity by up to 30%, as automation minimizes human error and enhances the workflow.

Tips: When selecting laser marking equipment, consider factors such as the material being marked and the desired marking speed to ensure optimal performance. Always consult with manufacturers to understand the specific capabilities of each laser type, tailoring your choice to your production needs. Additionally, regular maintenance of both laser sources and marking heads can prolong their lifespan and ensure consistent marking quality.

Laser marking technology encompasses various techniques, each tailored to specific applications and materials. The most common types include laser engraving, laser etching, and laser annealing. Laser engraving involves the removal of material to create a permanent mark, often used for intricate designs or logos on materials like metals and plastics. This method provides deep, durable markings suitable for industrial applications.

On the other hand, laser etching is a less aggressive process that melts the surface of the material rather than removing it. This technique creates a raised effect, ideal for high-precision marks, particularly on soft materials like wood and glass. Finally, laser annealing is utilized to change the color of metal without altering its surface profile. This method is commonly employed in the medical and semiconductor industries for its ability to produce visible marks without compromising the integrity of the material. Each of these techniques demonstrates the versatility of laser marking technology in meeting diverse marking needs across various sectors.

Laser marking technology has emerged as a pivotal tool across a multitude of industries, driven by its ability to deliver precision and permanence in marking applications. This technology utilizes focused laser beams to etch or engrave materials, resulting in high-contrast, durable marks that can withstand harsh environmental conditions. The adaptability of laser marking systems allows for intricate designs on complex shapes, making it suitable for applications in electronics, automotive, medical devices, and packaging. Its efficiency not only enhances productivity but also reduces waste, which is a critical factor in sustainable manufacturing.

The applications of laser marking span various sectors. In the automotive industry, for example, it is used for serial number identification and branding, ensuring traceability of components. In electronics, laser marking facilitates the precise labeling of critical components without damaging sensitive materials. Additionally, the medical sector employs this technology for marking surgical instruments and devices, where sterility and traceability are paramount. As industries continue to evolve towards advanced manufacturing practices, the integration of laser marking technology is expected to grow significantly, driven by its proven benefits in enhancing operational efficiency and product quality.

| Industry | Application | Materials Used | Benefits |

|---|---|---|---|

| Manufacturing | Part Identification | Metals, Plastics | Durable, High Precision |

| Automotive | VIN Marking | Aluminum, Steel | Tamper-proof, Permanent |

| Electronics | Component Marking | PCBs, Circuit Boards | Precision, Low Heat Affect |

| Packaging | Product Coding | Cardboard, Plastic | Fast, Non-contact |

| Medical | Instrument Marking | Stainless Steel, Plastics | Sterile, Clear Markings |

Laser marking technology has gained popularity across various industries due to its unique advantages, yet it comes with certain limitations. According to a market research report, the non-metal laser engraving machine market was valued at approximately $359.1 million in 2024 and is projected to reach around $575.9 million by 2032, reflecting a growth rate of 6.1%. This trend underscores the increasing reliance on laser marking for applications such as product identification, branding, and customization.

One of the key benefits of laser marking is its precision and durability. The technology enables high-resolution markings that are resistant to wear, making it ideal for labeling products in industries ranging from automotive to electronics. Additionally, laser marking is a non-contact process, which minimizes the risk of damaging the underlying material. However, it's essential to note that the technique may not be suitable for all materials; certain plastics or coatings may not withstand the heat generated during the laser marking process, leading to discoloration or deformation. Understanding both the benefits and limitations enables manufacturers to make informed decisions when integrating laser marking into their production processes.