1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

In the rapidly evolving landscape of manufacturing, the advent of advanced technologies continues to reshape traditional processes, with the laser marking machine standing out as a transformative tool. According to a report by MarketsandMarkets, the global laser marking market is projected to reach USD 4.5 billion by 2025, growing at a CAGR of 5.6%. This remarkable growth underscores the increasing adoption of laser marking machines across various industries, including automotive, electronics, and medical devices. These machines offer precision, reliability, and efficiency that enhance product identification and traceability, leading to improved quality control and reduced waste.

As manufacturers increasingly seek cost-effective and environmentally friendly solutions, the ability of laser marking machines to operate without inks and solvents further solidifies their role in revolutionizing manufacturing processes. This article will explore the myriad benefits and future implications of laser marking technology in the modern industrial environment.

The evolution of laser marking technology has significantly transformed manufacturing processes across various industries. Initially introduced as a niche application for specific marking tasks, laser marking has grown into a versatile and indispensable tool for manufacturers. According to a report by Markets and Markets, the global laser marking market is projected to reach USD 4.2 billion by 2025, growing at a CAGR of 7.5%. This growth is driven by the need for high precision, speed, and efficiency in production lines, where traditional marking methods often fall short.

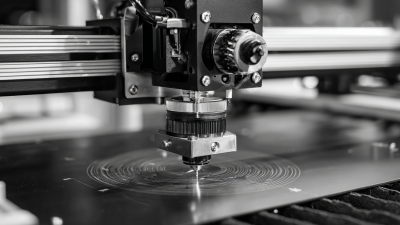

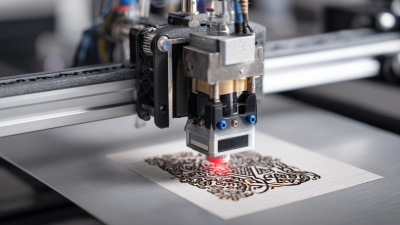

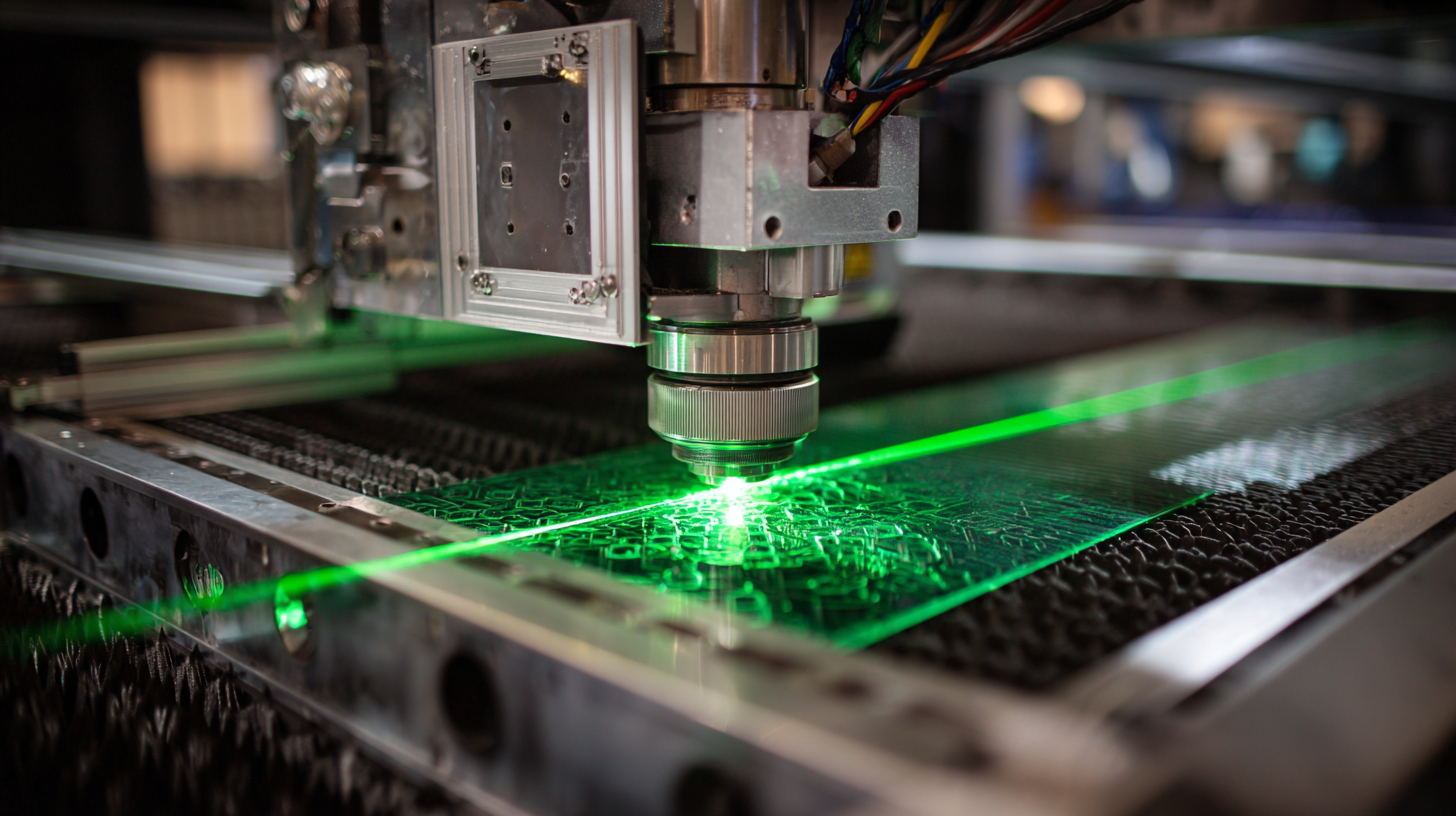

Modern laser marking machines utilize advanced technology, such as fiber lasers and CO2 lasers, to provide superior marking quality and maintain durability on diverse materials. The technology has advanced from simple coding to complex graphics and logos, enabling manufacturers to customize their products while enhancing brand recognition. Furthermore, laser marking minimizes waste and reduces the need for consumables, contributing to sustainable manufacturing practices.

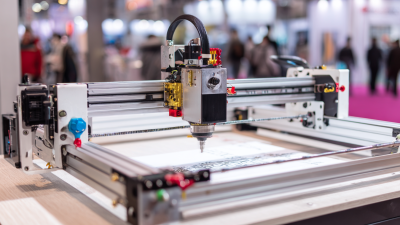

**Tips:** When integrating laser marking machines into your production line, consider conducting a comprehensive evaluation of your materials and marking requirements. This will help in selecting the right laser type and power settings for optimal performance. Additionally, schedule regular maintenance to ensure the longevity and efficiency of the machines, maximizing your return on investment.

The chart above illustrates the increasing adoption rate of laser marking technology in manufacturing processes from 2018 to 2023. As industries continue to seek greater precision and efficiency, laser marking machines have become essential tools, transforming traditional manufacturing practices.

Laser marking machines are transforming industrial applications by offering precision, efficiency, and versatility in marking processes. One of the key benefits is their ability to produce high-quality, permanent markings on a wide variety of materials. This durability ensures that the markings are resistant to wear, chemicals, and environmental factors, which is essential for industries where traceability and compliance are critical, such as aerospace, automotive, and medical manufacturing.

In addition to their remarkable marking quality, laser marking machines significantly reduce production time and costs. Unlike traditional marking methods, laser marking is a non-contact process that eliminates the need for physical tools, reducing wear and maintenance. Furthermore, the speed of laser marking allows for higher throughput, enabling manufacturers to meet tight deadlines without compromising on quality. The technology also supports quick changeovers, making it an ideal solution for companies that produce a diverse range of products, enhancing their flexibility in manufacturing.

| Benefit | Description | Applications | Industries |

|---|---|---|---|

| Precision | Highly accurate marking that maintains product integrity and aesthetics. | Barcodes, QR codes, serial numbers. | Electronics, automotive, medical devices. |

| Speed | Fast processing time, increasing production efficiency. | High-speed numbering, batch marking. | Food & beverage, pharmaceuticals. |

| Durability | Marks are resistant to wear, chemicals, and environmental factors. | Permanent markings for product safety and identification. | Aerospace, energy, heavy machinery. |

| Flexibility | Can mark on various materials including metals, plastics, and ceramics. | Custom logos, designs, and text. | Consumer goods, custom products. |

| Cost-Effectiveness | Low operational costs due to minimal maintenance and no consumables. | Bulk packaging labels, identification plates. | Logistics, warehousing, manufacturing. |

The comparative analysis of laser marking and traditional marking techniques reveals significant advantages for manufacturing processes. Laser marking machines utilize focused laser beams to engrave or mark materials with precision, offering unparalleled accuracy compared to traditional methods such as ink or mechanical engraving. This not only improves the quality of the markings but also enhances the speed of production, allowing manufacturers to meet the increasing demands for efficiency in modern industries.

Traditional marking techniques often struggle with durability and longevity of markings, especially when applied to diverse materials. In contrast, laser marking provides a permanent solution without the need for consumables, significantly reducing ongoing material costs. Moreover, advancements in laser technology, such as those showcased in recent research focusing on high-resolution imaging and particle tracking, showcase the potential for even further innovation in this field. As laser marking continues to evolve, it solidifies its position as a game-changer in manufacturing, enabling more sophisticated applications and contributing to the overall enhancement of production capabilities.

Future trends in laser marking technology indicate significant advancements that are set to redefine industry standards across manufacturing sectors. According to a report by Research and Markets, the global laser marking market is expected to reach $3.48 billion by 2026, growing at a CAGR of 6.5%. This growth is primarily driven by the increasing demand for automation and precision in manufacturing processes, with laser marking offering unparalleled accuracy and versatility in marking a variety of materials.

One of the key advancements in laser marking is the integration of artificial intelligence and machine learning algorithms, which enhance the operational efficiency and precision of marking machines. As industries move towards smart manufacturing, the adoption of Industry 4.0 principles fosters the use of connected laser marking systems that can adjust parameters in real-time based on production needs. Furthermore, with stricter regulations and standards in traceability and product identification, marking technologies that comply with these requirements will increasingly lead the market. The rise of eco-friendly laser marking solutions, such as fiber lasers that consume less energy and produce less waste, aligns with global sustainability goals, further cementing the relevance of laser marking in the future of manufacturing.

The laser marking machine market is anticipated to witness significant growth over the coming years, driven by advancements in technology and an increasing demand for precision in manufacturing. According to a report by MarketsandMarkets, the laser marking market is expected to reach USD 5.3 billion by 2025, growing at a CAGR of 5.6% from 2020 to 2025. This surge is largely attributed to the expanding automotive and electronics sectors, where laser marking ensures high accuracy and durability of markings on various materials.

Furthermore, a research forecast by Fortune Business Insights predicts that the global laser marking systems market will experience similar trends, with projections estimating it to reach USD 5.2 billion by 2028, expanding at a CAGR of 5.3% from 2021 to 2028. As industries strive for efficient and sustainable production processes, the integration of laser marking machines enhances operational efficiency, reduces material waste, and improves product traceability.

These factors underscore the transformative effect of laser technology in modern manufacturing and its essential role in meeting future production challenges.