1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

The 138th Canton Fair in 2025 serves as a pivotal platform for showcasing cutting-edge innovations in laser marking technology, a sector poised for significant growth as businesses increasingly seek precise and efficient marking solutions. According to a recent market report by Fortune Business Insights, the global laser marking market is expected to reach $5.8 billion by 2027, with a compound annual growth rate (CAGR) of 5.9%. This rapid expansion is driven by the growing demand for high-quality marking applications across various industries, including electronics, automotive, and packaging. As manufacturers strive for enhanced traceability and branding, laser marking technologies, which offer advantages like low operational costs and eco-friendliness, are becoming indispensable. At the upcoming fair, key industry players will unveil their latest advancements, reflecting not only current trends but also the future direction of laser marking solutions in a competitive global market.

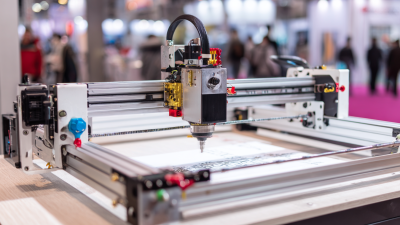

The 138th Canton Fair in 2025 showcased a remarkable array of innovative laser marking technologies, reflecting the rapid advancements within the industry. Recent reports from the International Laser Market Research indicate that the laser marking market is projected to grow at a CAGR of 6.5%, reaching approximately $5.1 billion by 2027. This growth is driven by an increasing demand for precision and efficiency in manufacturing processes, where laser marking provides a reliable solution for traceability and durability.

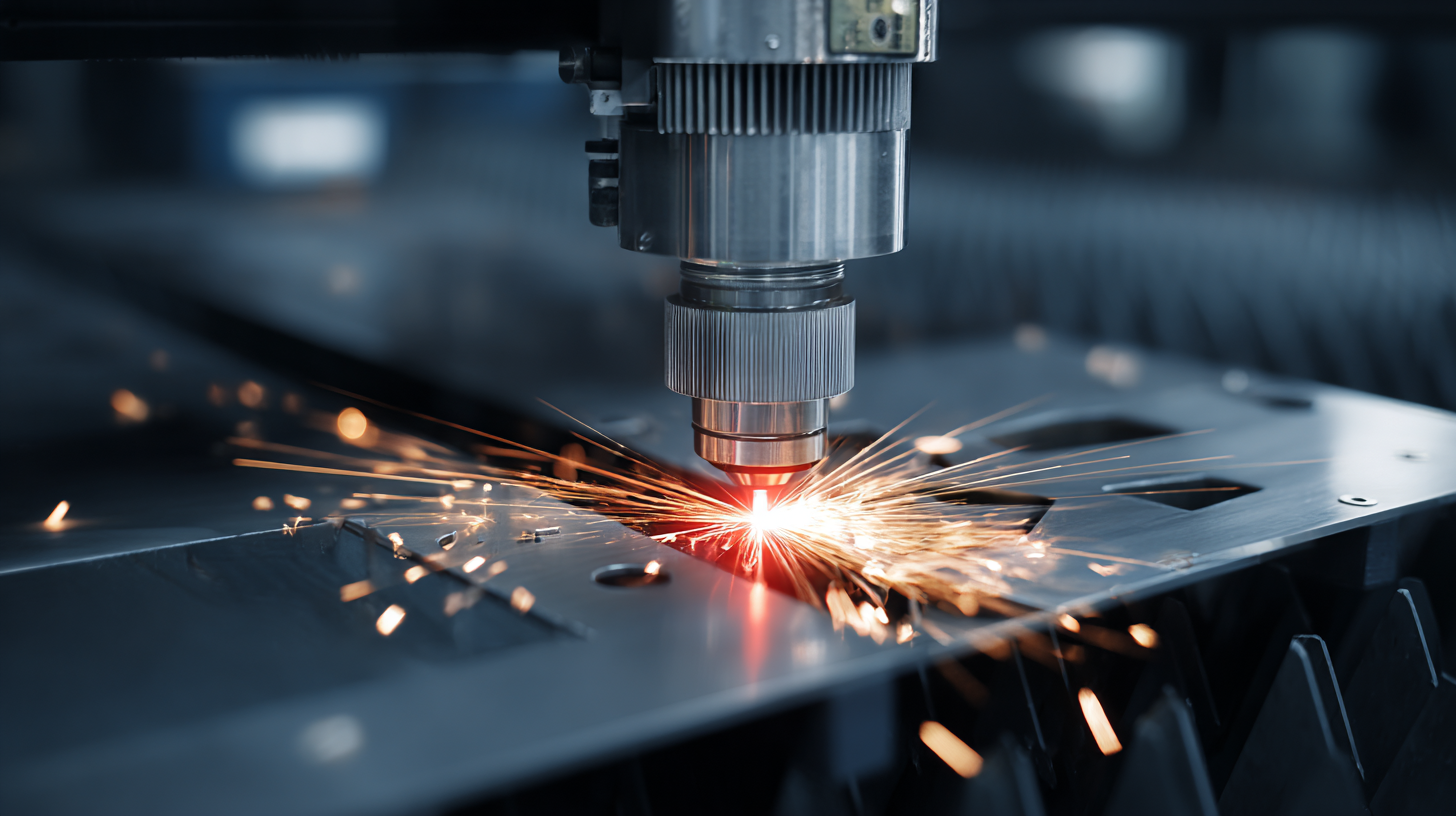

At the fair, exhibitors presented cutting-edge laser marking systems that incorporate advanced features such as high-speed processing and multi-material capabilities. For instance, one standout innovation was a compact, fiber laser marking machine that can mark up to 1,200 characters per second, significantly improving production timelines. Furthermore, the introduction of artificial intelligence in laser marking systems enhances accuracy and customization, allowing businesses to meet specific client needs more effectively. With such advancements on display, the Canton Fair serves as a critical platform for industry players to identify trends and harness the potential of laser technology in their operations.

| Technology Type | Applications | Market Growth (%) | Key Features | Sustainability Impact |

|---|---|---|---|---|

| Fiber Laser Marking | Metal, Plastic Tags | 15% | High Precision, Fast Speed | Low Energy Consumption |

| CO2 Laser Marking | Textiles, Wood | 12% | Versatile, Cost-Effective | Recyclable Materials Preferred |

| UV Laser Marking | Glass, Electronics | 20% | Minimal Heat, Finest Detail | Eco-Friendly Process |

| Laser Etching | Plastics, Leather | 10% | Detailed Textures, Durable | Waste Reduction Techniques |

The laser marking industry is set to experience significant growth through 2025, driven by advancements in technology and increasing demand across various sectors. According to a recent report by Market Research Future, the global laser marking market is projected to grow at a compound annual growth rate (CAGR) of 6.5% during the forecast period. This upward trend is primarily attributed to the burgeoning need for product customization and traceability in industries such as packaging, automotive, and electronics.

Particularly noteworthy is the expansion in the Asia-Pacific region, which is expected to dominate the market share due to rapid industrialization and the increasing adoption of automation in manufacturing processes. A report by Fortune Business Insights highlights that the demand for laser marking solutions is anticipated to rise as industries seek efficient and sustainable ways to meet regulatory compliance and enhance brand identity.

As laser technology continues to evolve, innovations such as fiber laser marking and UV lasers are gaining traction, offering enhanced precision and versatility, further propelling market growth.

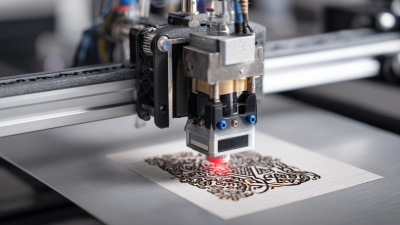

At the 138th Canton Fair in 2025, laser marking technology is poised to showcase its versatility across various sectors. The advancements in laser marking applications are significantly transforming manufacturing processes, emphasizing precision and efficiency. Industries such as electronics, automotive, and medical equipment are increasingly adopting laser marking solutions for product identification, branding, and traceability. The integration of laser marking systems allows companies to streamline their operations, reduce waste, and maintain compliance with regulatory standards.

In addition to traditional applications, emerging trends highlight the role of artificial intelligence in enhancing laser marking efficiency. Companies that have embraced AI technology are utilizing it to optimize laser marking processes through intelligent automation and real-time data analysis. This innovation not only improves the quality of laser marks but also opens up new avenues for customization in product design. As businesses continue to explore these technological advancements at the Canton Fair, the potential for laser marking to drive innovation across diverse sectors becomes increasingly apparent.

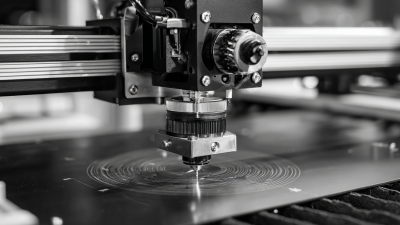

The comparative analysis of laser marking versus traditional marking techniques highlights significant advancements in the industry, particularly in the context of product identification. Laser marking stands out due to its precision and permanence, providing a clearer and more detailed identification compared to conventional methods such as inkjet printing or labeling. This technology eliminates the risk of fading or smudging, ensuring that critical information like production dates, batch numbers, and traceability codes remain intact throughout a product's life cycle.

The comparative analysis of laser marking versus traditional marking techniques highlights significant advancements in the industry, particularly in the context of product identification. Laser marking stands out due to its precision and permanence, providing a clearer and more detailed identification compared to conventional methods such as inkjet printing or labeling. This technology eliminates the risk of fading or smudging, ensuring that critical information like production dates, batch numbers, and traceability codes remain intact throughout a product's life cycle.

Moreover, the increasing demand for sustainable and innovative packaging solutions is pushing more industries towards adopting laser marking technologies. For instance, the recent trend of “no-label” designs aims to reduce plastic waste, highlighting an environmental consciousness that aligns with laser marking’s capabilities. Unlike traditional methods that use labels and inks, laser marking directly engraves onto surfaces, thus minimizing material usage and supporting eco-friendly initiatives. As manufacturers seek to not only improve product quality but also enhance brand reputation through sustainability, laser marking presents a compelling alternative to traditional marking techniques.

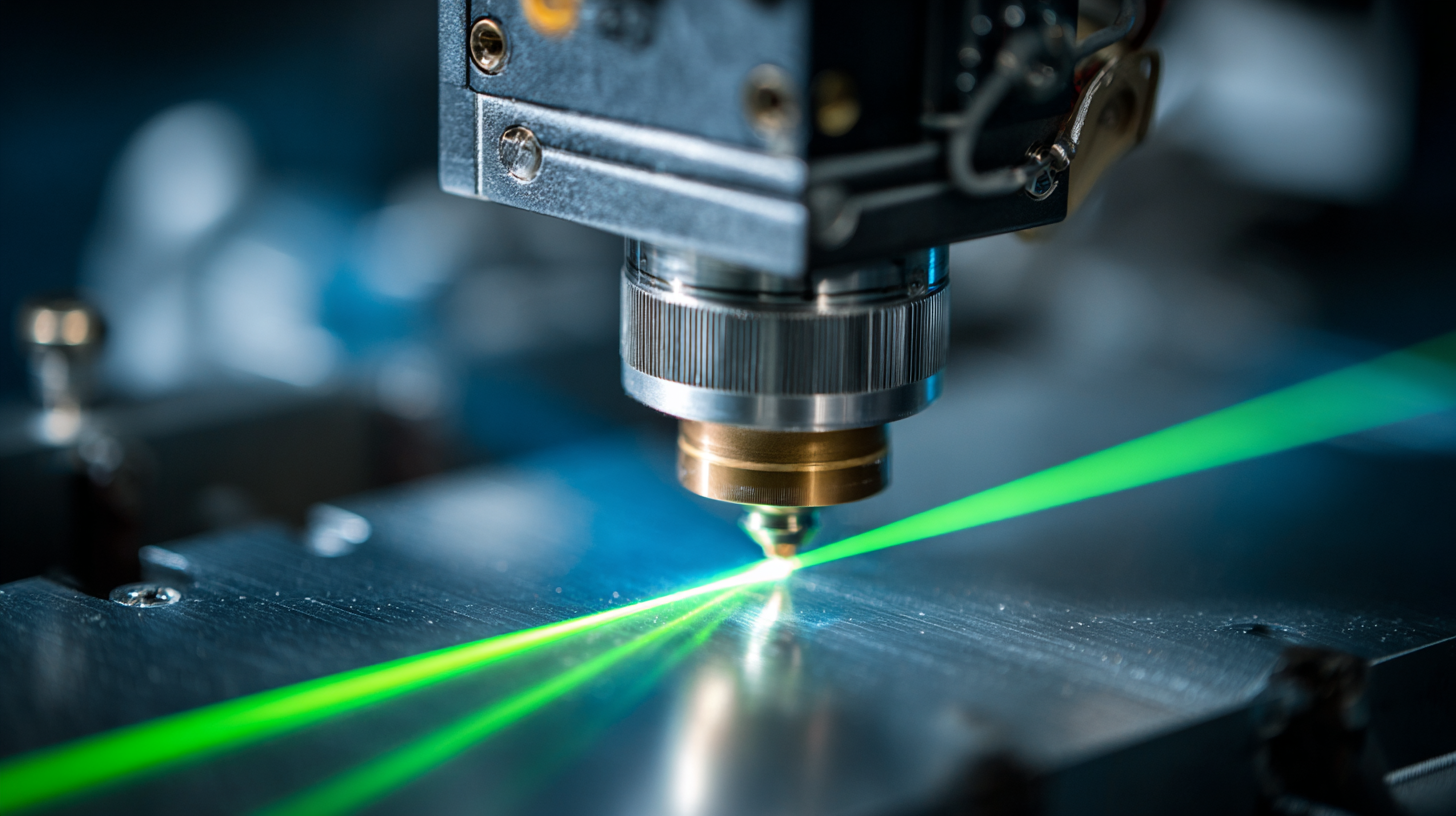

At the 138th Canton Fair in 2025, the spotlight was on sustainability trends shaping the future of laser marking practices. Industry reports indicate that the global laser marking market is projected to grow from $3.5 billion in 2022 to approximately $5.8 billion by 2028, reflecting a compound annual growth rate (CAGR) of 8.5%. This growth is largely attributed to increased demand for environmentally friendly manufacturing processes, which has propelled companies to adopt laser marking technologies that minimize waste and energy consumption.

One of the notable innovations showcased at the fair was the development of fiber laser systems that use significantly less energy compared to traditional marking methods. For instance, data from the Laser Institute of America highlights that fiber lasers are up to 50% more efficient than their CO2 counterparts, which translates into lower operational costs and reduced environmental impact. Additionally, eco-conscious manufacturers are increasingly utilizing recyclable materials for marking substrates, further enhancing the sustainability factor in production. These trends underscore a collective industry shift toward more responsible practices that not only meet regulatory demands but also align with consumer preferences for greener products.