1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

As we approach the 138th China Import and Export Fair in 2025, the spotlight is set to shine on the groundbreaking advancements in laser welding machines. This event serves as a pivotal platform for showcasing the latest innovations that redefine manufacturing and production standards globally.

The integration of laser technology into welding processes has not only enhanced precision and efficiency but also significantly reduced operational costs and environmental impact. Exhibitors and attendees will have the unique opportunity to explore how these cutting-edge laser welding machines are driving progress across various industries, from automotive to aerospace.

With a focus on sustainability and technological advancement, the fair promises to unveil a range of state-of-the-art products and solutions that highlight the future of welding in a rapidly evolving market. As the industry embraces these innovations, the discussions and demonstrations at the fair will undoubtedly pave the way for new applications and opportunities within the realm of laser welding technology.

At the 138th China Import and Export Fair 2025, innovative laser welding technologies took center stage, showcasing groundbreaking advancements that promise to redefine manufacturing processes across various industries. These technologies were highlighted in numerous presentations and exhibitions, demonstrating their potential to enhance efficiency, precision, and safety in welding applications. According to a recent industry report by ResearchAndMarkets, the laser welding market is projected to grow at a compound annual growth rate (CAGR) of 5.5% between 2023 and 2030, driven by the increasing demand for automation and high-quality welding solutions.

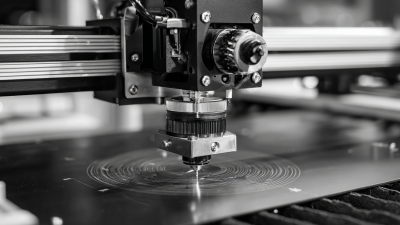

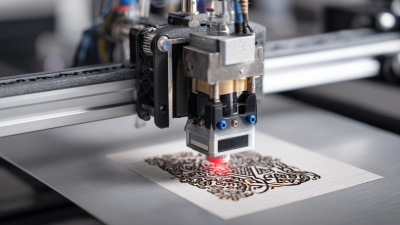

One of the standout innovations presented was the development of fiber laser welding machines, which offer significant advantages over traditional welding techniques. These machines utilize high-powered laser beams to melt and fuse materials together with exceptional accuracy, producing strong welds while minimizing heat-affected zones. This not only reduces the risk of material distortion but also shortens production cycles. A report by Allied Market Research indicates that the fiber laser segment alone is expected to account for over 40% of the total laser welding market, underscoring its rising popularity among manufacturers.

Tips for industries looking to adopt these technologies include conducting thorough assessments of specific needs and compatibility with existing systems. It's also crucial to invest in training operators on new equipment to maximize productivity and minimize error rates. As these innovations continue to emerge, staying updated with the latest advancements will be key to maintaining a competitive edge in the market.

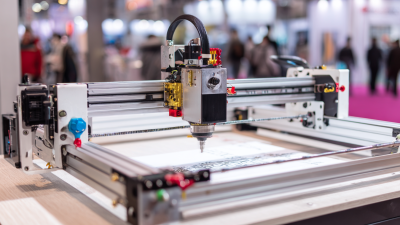

At the 138th China Import and Export Fair in 2025, innovations in laser welding machinery are set to take center stage. The market for laser welding technology is projected to reach $6.5 billion by 2028, reflecting a compound annual growth rate (CAGR) of 8.4% from 2023 to 2028, according to a recent report by Research and Markets. This growth is driven by advancements in technology, including the integration of AI and machine learning, which enhance precision and efficiency in production lines. Industries such as automotive and aerospace are increasingly adopting these state-of-the-art machines to improve their manufacturing processes.

Tips: When considering investments in laser welding machines, prioritize models that offer adaptability to various materials. This flexibility can significantly enhance operational efficiency and cost-effectiveness in your production.

In addition to technological advancements, the trend towards automation in laser welding is gaining momentum. A report by MarketsandMarkets indicates that automated laser welding systems are expected to capture 60% of the market share by 2025. Companies that adapt to this trend not only enhance productivity but also reduce labor costs, leading to improved ROI.

Tips: Stay informed about emerging technologies, as integrating the latest features can provide a competitive edge in the evolving landscape of laser welding machinery.

| Category | 2023 Market Size (Million USD) | 2025 Projected Market Size (Million USD) | CAGR (2023-2025) | Key Innovations |

|---|---|---|---|---|

| Fiber Laser Welding Machines | 1500 | 2100 | 22% | High-speed operations, precision control |

| CO2 Laser Welding Machines | 800 | 1000 | 12% | Versatile applications, improved beam quality |

| Pulsed Laser Welding Machines | 600 | 900 | 25% | Enhanced control over heat input, minimal distortion |

| Hybrid Laser Welding Machines | 400 | 700 | 35% | Combines advantages of fiber and CO2 lasers |

The 138th China Import and Export Fair in 2025 showcased significant advancements in laser welding machines, highlighting the transformative impact of Industry 4.0. This iteration of the fair emphasized the integration of smart manufacturing technologies, enabling laser welding machines to operate with higher precision and efficiency. The incorporation of real-time data analytics and AI-driven automation is allowing manufacturers to optimize their operations, reduce waste, and enhance quality control.

Furthermore, the advent of IoT (Internet of Things) capabilities has revolutionized how laser welding machines communicate and function within production lines. These innovations facilitate predictive maintenance, as machines can now self-diagnose potential issues before they escalate into costly breakdowns. By leveraging Industry 4.0 principles, companies are not only improving productivity but are also fostering a more sustainable manufacturing environment. This shift towards automated and interconnected systems illustrates the dynamic evolution within the welding industry, setting a new standard for performance and innovation at the fair.

The global laser welding market is poised for significant growth from 2024 to 2032, driven by increasing applications across various industries. By 2024, the market is expected to reach approximately $747.8 million, with projections indicating an escalation to around $895.0 million by 2032. This translates to a compound annual growth rate (CAGR) of 2.3%. Key sectors propelling this growth include automotive and transportation, where precision and efficiency in welding processes are vital, as well as aerospace and defense, where advanced welding technologies ensure durability and safety in critical applications.

In addition to laser welding, the fiber laser market is also on an upward trajectory, anticipated to soar from $4.63 billion in 2025 to $10.75 billion by 2032, demonstrating a remarkable CAGR of 12.8%. Similarly, the laser cutting machine segment is set to expand significantly, projected to grow from $6.85 billion to $14.14 billion during the same period, with a strong annual growth rate of 10.9%. These trends illustrate the robust demand for innovative welding and cutting solutions, highlighting the transformative impact of laser technology in the industrial landscape.

The 138th China Import and Export Fair in 2025 showcased remarkable advancements in laser welding technology, with numerous case studies highlighting successful applications across various industries. One standout presentation detailed the use of laser welding in the automotive sector, where precision and efficiency are paramount. A major automotive manufacturer shared insights on how they integrated laser welding into their production line, significantly reducing cycle times while maintaining superior joint quality. This innovation not only minimized material waste but also enhanced the overall structural integrity of the vehicles being produced.

Another compelling case study came from the aerospace industry, where the use of laser welding has transformed traditional fabrication methods. A leading aerospace company presented a project focusing on lightweight components, demonstrating how laser welding enabled the assembly of intricate structures without compromising strength. This method allowed for the use of advanced materials, ultimately leading to enhanced fuel efficiency in aircraft design. The presentations at the fair underscored the versatility of laser welding technology and its critical role in driving innovation across diverse sectors, paving the way for future advancements in manufacturing processes.