1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

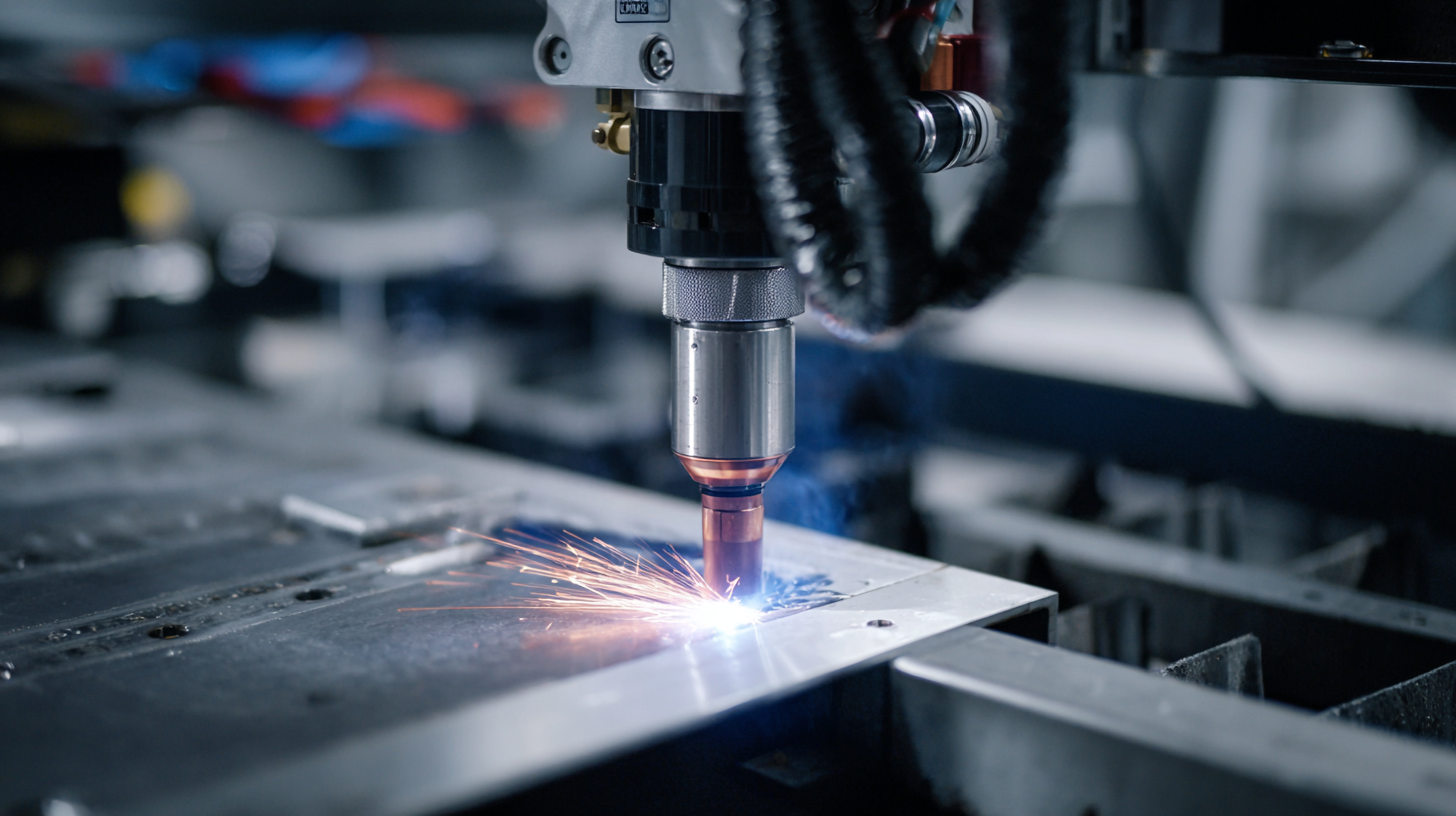

The manufacturing industry is on the brink of transformation, driven by advancements in technology such as the handheld laser welding machine. According to a report by Allied Market Research, the global welding equipment market is projected to reach $35.52 billion by 2025, with laser welding playing a pivotal role in this growth.

Handheld laser welding machines offer unparalleled precision and versatility, making them ideal for various applications across sectors, from automotive to aerospace. The ability to perform high-quality welds with reduced heat input not only enhances productivity but also minimizes the risk of material distortion, a common challenge faced by traditional methods. As industries seek efficient and cost-effective solutions, the rise of handheld laser welding machines represents a significant shift in fabrication processes, paving the way for a more innovative and automated future in manufacturing.

Handheld laser welding machines offer unparalleled precision and versatility, making them ideal for various applications across sectors, from automotive to aerospace. The ability to perform high-quality welds with reduced heat input not only enhances productivity but also minimizes the risk of material distortion, a common challenge faced by traditional methods. As industries seek efficient and cost-effective solutions, the rise of handheld laser welding machines represents a significant shift in fabrication processes, paving the way for a more innovative and automated future in manufacturing.

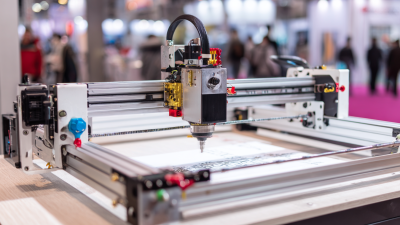

The rise of handheld laser welding machines represents a significant advancement in modern manufacturing processes, changing the way professionals approach intricate fabrication tasks. These portable devices allow for precision welding in tight spaces and on various materials, fostering innovation in industries such as automotive, aerospace, and electronics. Unlike traditional welding methods, handheld laser welding is characterized by its speed and cleanliness, significantly reducing the time taken for each project while producing minimal waste.

Moreover, the versatility of handheld laser welders enables manufacturers to adapt quickly to changing market demands. As industries increasingly prioritize flexibility and efficiency, these machines empower workers to execute complex welds with ease, thereby streamlining production lines. Additionally, the integration of advanced technologies, such as automation and real-time monitoring, enhances quality control, ensuring consistent results with reduced labor costs. As the manufacturing landscape evolves, handheld laser welding is set to become an essential tool in achieving both precision and agility in production.

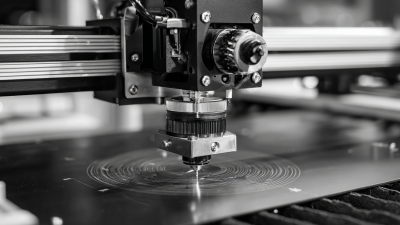

The advent of handheld laser welding machines is transforming the manufacturing landscape by offering significant advantages over traditional welding methods. According to a report by MarketsandMarkets, the laser welding market is projected to reach $3.3 billion by 2026, highlighting the increasing adoption of these advanced technologies. One of the primary benefits of handheld laser welding is its precision; with a focused laser beam, operators can achieve high-quality welds with minimal thermal distortion, ensuring superior weld integrity and reduced post-welding cleanup.

Another key advantage is the enhanced efficiency and mobility provided by handheld laser machines. Unlike traditional welding equipment, which often requires extensive setup and can be cumbersome to maneuver, handheld lasers allow welders to work in tight spaces and on a variety of surfaces, significantly reducing production time. According to an industry analysis, companies that have transitioned to handheld laser welding have reported a reduction in labor costs by up to 30%, along with an increase in overall productivity.

Tips: When considering the transition to handheld laser welding, ensure your team undergoes proper training to maximize the benefits of this technology. Additionally, invest in high-quality machines that suit your specific manufacturing needs, as this can lead to substantial long-term savings and improved operational efficiency.

Handheld laser welding machines are transforming the landscape of manufacturing across various industries through their innovative applications. With the ability to produce high-quality welds quickly and efficiently, these machines are gaining traction in sectors such as automotive, aerospace, and electronics. The precision and versatility of handheld laser welders enable manufacturers to undertake complex tasks, such as welding intricate components or repairing delicate parts, which were previously challenging using traditional welding methods.

Additionally, the portability of handheld laser welding machines allows operators to tackle projects in diverse environments, from production lines to remote job sites. This flexibility is particularly advantageous in industries like construction and maintenance, where on-site repairs are often necessary.

Moreover, the reduced heat-affected zones mean that the risk of warping or damaging sensitive materials is minimized, leading to superior end products. As businesses continue to embrace these advanced tools, the future of manufacturing looks promising, marked by increased efficiency, enhanced product quality, and greater adaptability to evolving industrial needs.

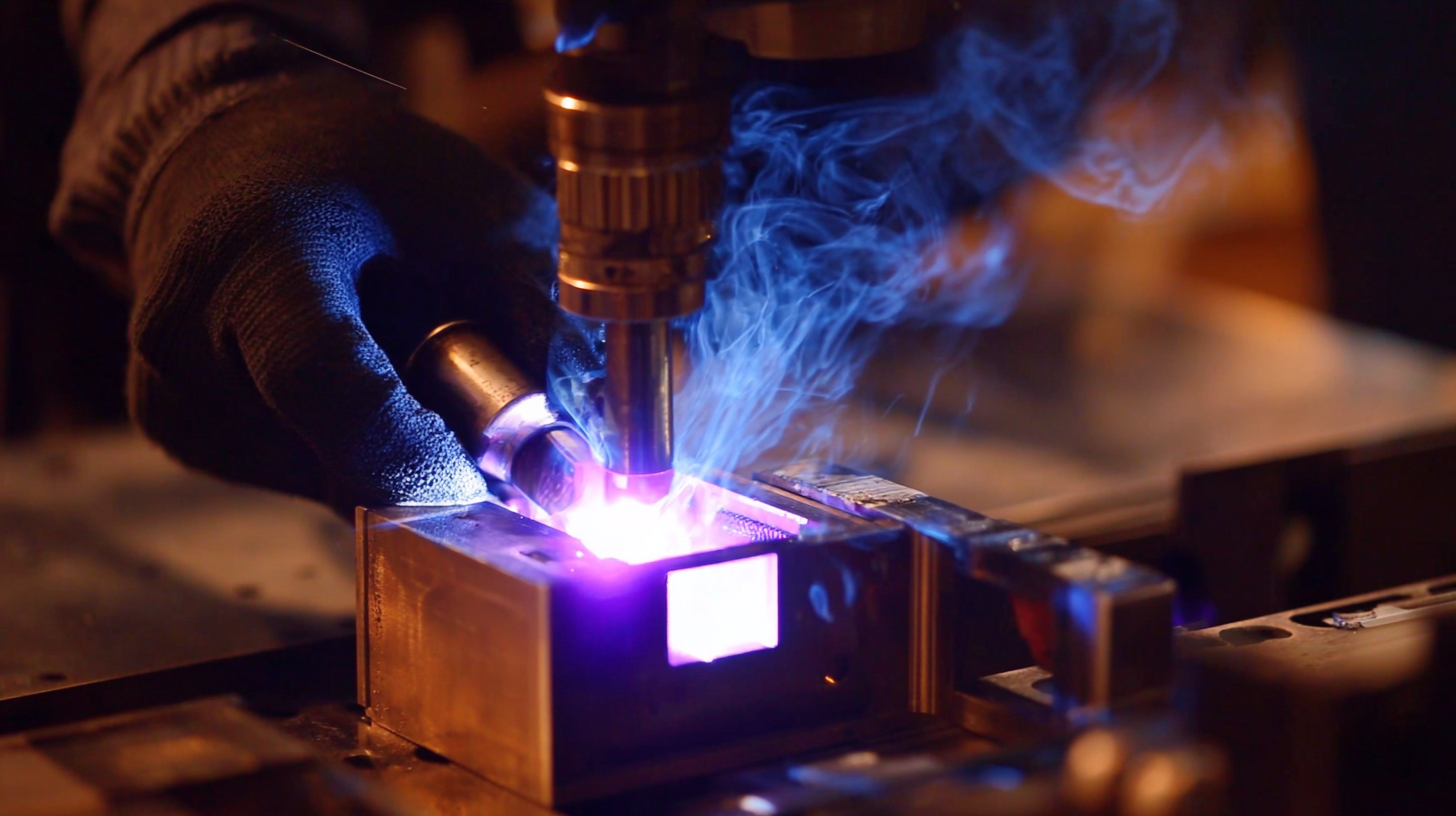

The integration of digital technology in handheld laser welding machines marks a significant shift in manufacturing efficiency and precision. By utilizing advanced software and automation, these systems allow for real-time monitoring and adjustments during the welding process. This capability not only enhances the quality of the welds but also reduces the time required for setup and execution. With features like integrated sensors and data analytics, manufacturers can optimize parameters such as speed and power output, ensuring that each weld meets the desired specifications.

Additionally, digital technology facilitates better training and support for operators. Through augmented reality (AR) and virtual reality (VR) interfaces, workers can receive hands-on experience and guidance without the risks associated with traditional training methods. This technological enhancement leads to a more skilled workforce capable of leveraging the full potential of handheld laser welding machines. As digital tools continue to evolve, they promise to reshape the landscape of manufacturing, making processes not only more efficient but also more adaptable to the unique needs of various industries.

The integration of artificial intelligence (AI) into handheld laser welding machines is set to transform the manufacturing landscape dramatically. This technology allows for real-time data analysis, optimizing welding parameters and enhancing precision. As AI algorithms learn from previous welding operations, they can predict the best settings for different materials and thicknesses, reducing both time and waste in production processes. Moreover, AI can also enhance safety by monitoring environmental conditions and operator performance, alerting workers to potential hazards.

Tips: When implementing AI-driven welding systems, ensure that your workforce receives proper training to leverage the full potential of the technology. Regularly update the software to benefit from the latest innovations and tweaks in AI performance.

As we look ahead, the trend of combining AI with handheld laser welding will streamline fabrication processes, making them more efficient and adaptable. Manufacturers who embrace this integration will not only improve their output but will also stay competitive in a rapidly evolving market. By staying abreast of these advancements, businesses can position themselves at the forefront of industry 4.0, ready to tackle future challenges effectively.

Tips: Collaborate with technology providers to create custom AI solutions that address specific challenges in your welding operations. Continuous assessment of your welding processes will help identify areas where AI can deliver significant improvements.