1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

As industries continuously evolve, the introduction of laser machines has emerged as a pivotal force in redefining manufacturing standards. According to a recent report by MarketsandMarkets, the global laser machine market is projected to reach $8.4 billion by 2026, growing at a CAGR of 6.9%. This growth underscores the increasing adoption of laser technology across various sectors, including automotive, aerospace, and electronics, where precision and efficiency are paramount. Laser machines not only enhance the accuracy of cutting and engraving processes but also contribute to reduced material wastage and energy consumption. As manufacturers increasingly seek to integrate smart technologies, the role of laser machines in facilitating automation and data-driven decision-making becomes more critical. This exploration into the future of manufacturing highlights how laser machines are revolutionizing industry standards, paving the way for a more innovative and sustainable manufacturing landscape.

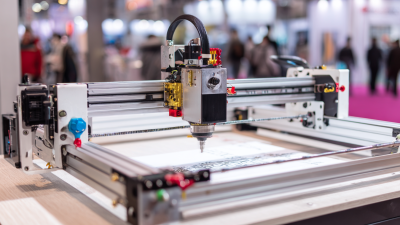

The evolution of laser technology in manufacturing has marked a significant turning point in the production landscape. Initially introduced as a niche tool for precise cutting and engraving, lasers have transformed into versatile machines that enhance efficiency and accuracy across various industries. Over the years, advancements in laser technology have led to the development of high-powered fiber and solid-state lasers, enabling manufacturers to cut through a wider range of materials with reduced energy consumption. This shift not only lowers operational costs but also drives sustainability, as companies increasingly seek greener production methods.

Moreover, the integration of advanced laser systems with automation and artificial intelligence is pushing the boundaries of what is achievable in manufacturing. Smart lasers now operate alongside robotics, adapting in real-time to the intricacies of production lines. This synergy enhances overall productivity, allowing manufacturers to produce more complex designs at unprecedented speeds. As laser technology continues to evolve, it opens up new possibilities for customization and innovation, positioning it as a cornerstone of modern manufacturing processes that meet the demands of an ever-changing market.

Laser machines are fundamentally transforming the landscape of modern manufacturing, driven by their unmatched precision and efficiency. According to recent market analysis, the global laser cutting machine market is poised to reach approximately $6.5 billion by 2025, expanding at a compound annual growth rate (CAGR) of around 5.5%. This growth is largely attributed to the rising demand for automation and high-quality production across various sectors, including automotive, aerospace, and electronics.

Key advantages of laser machines lie in their versatility and reduced operational costs. For instance, fiber laser systems, which hold the largest market share today, are favored for their efficiency in cutting a wide range of materials with minimal energy consumption. Additionally, the integration of robotics with semi-automatic laser cutting machines enhances the overall production rate, making it an ideal choice for manufacturers looking to optimize workflows. As industries continue to adopt these advanced technologies, the impact of COVID-19 has further accelerated the shift towards contactless manufacturing processes, reinforcing the importance of laser machines in achieving higher standards in production efficiency.

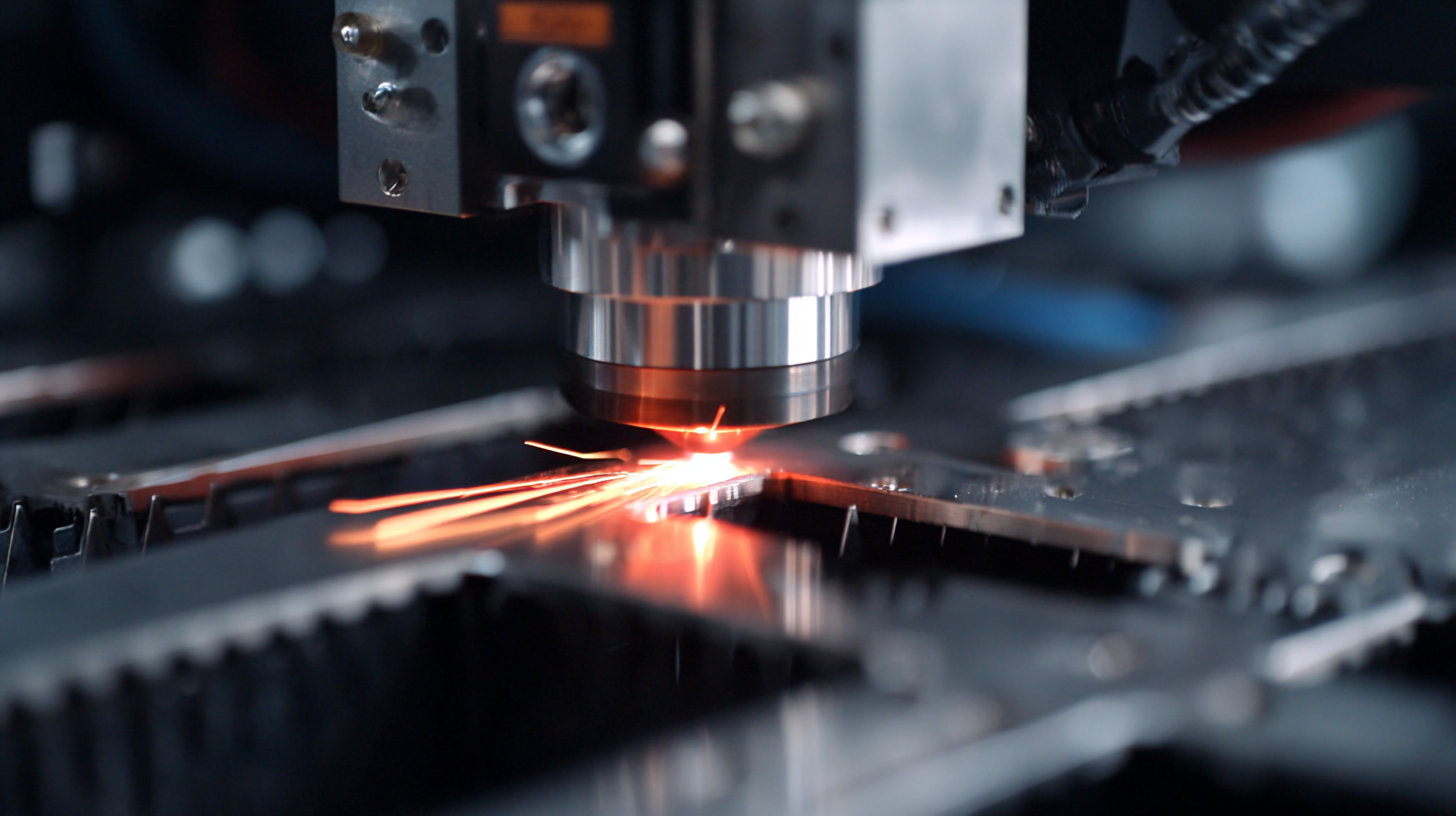

The manufacturing landscape is rapidly evolving, with laser machines taking center stage in a transformative shift away from traditional manufacturing methods. According to a report by IBISWorld, the adoption of laser technology in manufacturing is expected to grow at an annual rate of 9.3% from 2021 to 2026. This surge can be attributed to the superior precision and efficiency that laser machines offer, reducing material waste and ensuring higher-quality products. For instance, laser cutting can achieve tolerances as tight as ±0.1 mm, compared to traditional methods that often struggle with greater variances.

In a side-by-side comparison, laser machines demonstrate significant advantages over conventional techniques. A study conducted by Deloitte highlights that laser machining reduces production time by up to 50%, enabling manufacturers to respond more swiftly to market demands. Furthermore, operating costs are lower since laser machines require less maintenance and produce minimal scrap material, leading to lower overall expenses. These operational efficiencies not only enhance productivity but also support sustainable practices in manufacturing, aligning with the growing emphasis on eco-friendly production methods.

Laser technology is transforming various industries by accelerating production processes and enhancing precision. In the automotive sector, manufacturers are increasingly adopting laser cutting and welding techniques to streamline assembly lines. These advancements allow for lighter, more fuel-efficient vehicles by utilizing thinner materials without compromising structural integrity. The ability to execute intricate designs with high accuracy has also enabled automotive companies to innovate in design, offering more aesthetic and functional vehicles.

In the aerospace industry, the impact of laser machines is equally significant. Laser technology facilitates the manufacturing of complex components that are critical for performance, while also meeting stringent safety regulations. By enabling non-contact processing, lasers reduce the risk of damage to sensitive materials and components. Furthermore, the precision of laser machining increases material utilization, leading to reduced waste and cost-effectiveness in production.

The electronics sector is experiencing upheaval as well, with laser machines accelerating the production of circuit boards and electronic components. The ability to deliver micro-machining with unparalleled accuracy allows manufacturers to create increasingly compact and efficient devices. This efficiency not only speeds up production times but also meets the growing demand for miniaturization in consumer electronics, illustrating the widespread benefits of laser technology across diverse fields.

The landscape of laser manufacturing is witnessing a transformative evolution, driven by cutting-edge technologies and robust governmental support. In China, the industrial laser market is anticipated to reach a staggering scale of approximately 89.9 billion yuan by 2024, reflecting the country's position as the largest player in this sector. This rapid growth is not merely numerical; it signifies a significant shift in manufacturing standards and capabilities. The integration of advanced technologies within laser processing equipment is enabling manufacturers to achieve unprecedented precision, efficiency, and flexibility in production.

Future trends in the laser manufacturing domain highlight innovations such as smart integration and additive manufacturing. The upcoming 2025 Laser Manufacturing and Additive Manufacturing Innovation Development Conference and Exhibition aims to encapsulate these trends by focusing on themes of innovation and intelligent fusion. This event will serve as a platform for industry leaders to converge, evaluate national development strategies, and explore the intricacies of laser technology’s evolution. Such initiatives are vital for fostering new productive forces and ensuring the industry adapts to the changing technological landscape, thereby defining the future trajectory of manufacturing.

| Application | Laser Type | Industry Impact | Future Trends |

|---|---|---|---|

| Metal Cutting | Fiber Laser | High precision, reduced waste | Increased automation and efficiency |

| 3D Printing | Powder Bed Fusion | Rapid prototyping, custom designs | Advanced materials and hybrid processes |

| Engraving | CO2 Laser | Increased personalization options | Integration with design software |

| Welding | YAG Laser | Strong joints, less warping | Smart systems for quality control |