1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

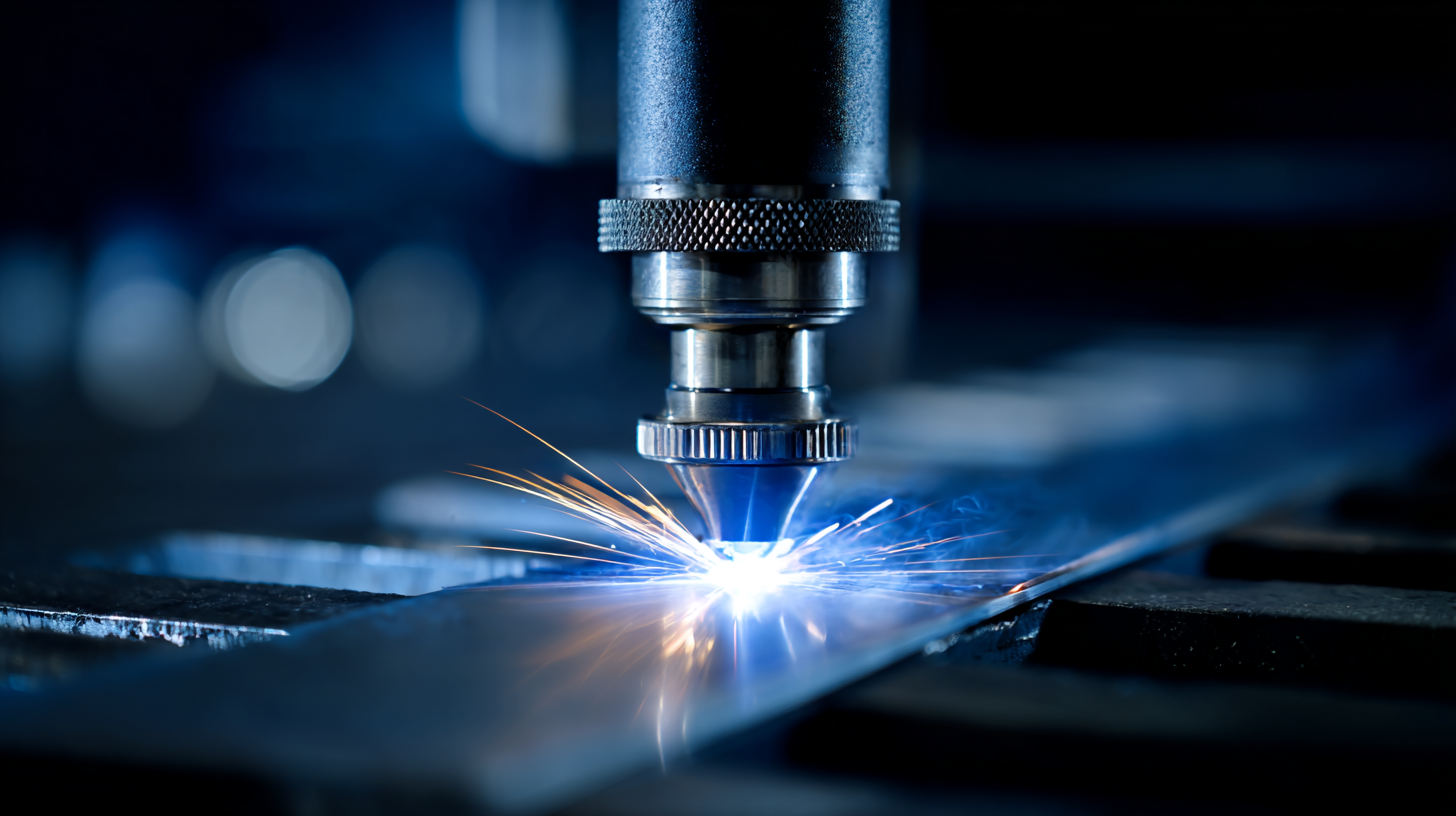

The manufacturing industry is undergoing a significant transformation, driven by advancements in technology and the increasing demand for precision and efficiency. Among these innovations, the laser welding machine has emerged as a game-changer, offering unmatched accuracy and speed in various applications. According to a report by MarketsandMarkets, the laser welding market is projected to reach USD 1.3 billion by 2025, growing at a CAGR of 5.2%. This growth is largely attributed to the rising adoption of laser welding in industries such as automotive, aerospace, and electronics, where the need for high-quality welds is paramount. The ability of laser welding machines to produce strong, clean joints with minimal heat-affected zones not only enhances the structural integrity of components but also optimizes production processes, reducing waste and downtime. As manufacturers explore the future of fabrication, understanding the transformative potential of laser welding technology is essential for maintaining competitive advantage in an increasingly automated landscape.

The evolution of laser welding technology signifies a monumental shift in manufacturing practices, unlocking unprecedented precision and efficiency. By 2024, the laser equipment industry in China is set to surpass a staggering market scale of 1070 billion yuan, with laser cutting equipment accounting for over 40% of this market. The increasing demand for advanced manufacturing technologies is driving this rapid growth, propelled by a compound annual growth rate of 10.25% since 2023. This reflects not only advancements in laser welding machines but also a broader trend of upgrading the nation's manufacturing capabilities to enhance productivity and quality.

As the global market for laser welding technology is projected to grow from approximately 747.8 million USD in 2024 to nearly 895 million USD by 2032, with a compound annual growth rate of 2.3%, the implications for various industries are profound. The integration of laser welding technology into manufacturing processes enables improved joint quality, reduces material waste, and increases the speed of production. As companies harness these advancements, laser welding machines are poised to redefine conventional manufacturing techniques, setting a new standard for excellence in the field.

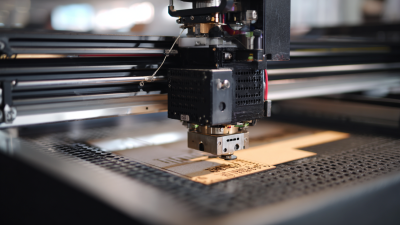

Laser welding technology is paving the way for significant advancements in manufacturing techniques. Its ability to deliver precise, high-quality welds with minimal thermal distortion makes it a preferred choice over traditional welding methods, which often lead to issues such as warping and excess heat-affected zones. One of the key advantages of laser welding is its speed; the process can be performed much faster than conventional methods, increasing overall productivity and efficiency in manufacturing.

Additionally, laser welding allows for greater versatility in terms of materials that can be joined. It is compatible with a wide range of metals and allows for the welding of thinner materials without compromising the integrity of the joint. As industries increasingly shift towards automation and smart manufacturing practices, the benefits of laser welding become even more apparent. According to recent market projections, the global laser welding technology market is expected to grow from approximately $747.8 million in 2024 to $895.0 million by 2032, with a compound annual growth rate of 2.3%. This growth reflects the rising adoption of laser welding in various sectors, highlighting its critical role in shaping the future of fabrication.

Laser welding technology is transforming manufacturing processes across multiple industries, offering precision and efficiency that traditional methods struggle to match. According to a report by MarketsandMarkets, the global laser welding market is projected to grow from $2.0 billion in 2020 to $3.8 billion by 2025, reflecting a compound annual growth rate (CAGR) of 14.2%. This growth highlights the increasing adoption of laser welding in sectors such as automotive, aerospace, and electronics, where stringent quality and speed requirements are paramount.

In the automotive industry, for instance, laser welding is instrumental in assembling lightweight and complex structures, which are crucial for enhancing fuel efficiency and reducing emissions. A study by the International Journal of Automotive Engineering illustrates that laser welding can enhance joint strength by up to 30% compared to conventional welding methods. Similarly, in the aerospace sector, precision and reliability are critical, and laser welding is utilized to bond materials that are difficult to weld with traditional techniques, facilitating the production of aircraft components that meet stringent safety standards. The versatility of laser welding continues to make it an indispensable tool across various applications, underscoring its role in the evolution of modern manufacturing.

The integration of automation and artificial intelligence (AI) into fabrication processes marks a transformative era for manufacturing. Automation enhances efficiency, precision, and consistency, substantially reducing human error and labor costs.

Laser welding machines exemplify this shift, enabling swift and accurate joining of materials that were once time-consuming and prone to mistakes. These machines can operate around the clock, ensuring that production lines remain active and output remains high.

Laser welding machines exemplify this shift, enabling swift and accurate joining of materials that were once time-consuming and prone to mistakes. These machines can operate around the clock, ensuring that production lines remain active and output remains high.

AI further bolsters this innovation by enabling predictive maintenance and real-time monitoring of equipment. Through advanced algorithms, AI systems analyze performance data, identifying potential issues before they lead to costly downtimes. This capability not only maximizes operational efficiency but also extends the lifespan of expensive machinery. As automation and AI continue to evolve, manufacturers will find themselves empowered to create more complex products with less waste, ultimately leading to a more sustainable fabrication landscape.

The implementation of laser welding technology in manufacturing brings promising advancements, but it is not without its challenges. One of the primary hurdles is the high initial investment in equipment, which can deter small to medium-sized enterprises from integrating this technology. Additionally, the need for skilled operators capable of managing complex laser systems poses another significant challenge. Training programs are essential to bridge this gap and ensure safe and efficient operation of the machines.

Tips for overcoming these challenges include assessing the long-term benefits of laser welding versus initial costs. Companies should also consider collaborating with equipment manufacturers for leasing options that reduce upfront expenses. Moreover, investing in employee training and skill development programs can enhance workforce capabilities and ultimately lead to greater productivity and innovation in manufacturing processes.

Another critical area of concern is the adaptability of laser welding to various materials. Not all materials respond well to laser welding, which requires manufacturers to experiment and optimize parameters for different substances. Conducting thorough material testing before full-scale implementation can help identify the best practices and reduce waste.