1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

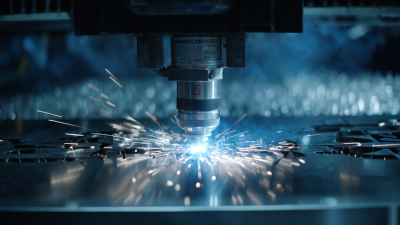

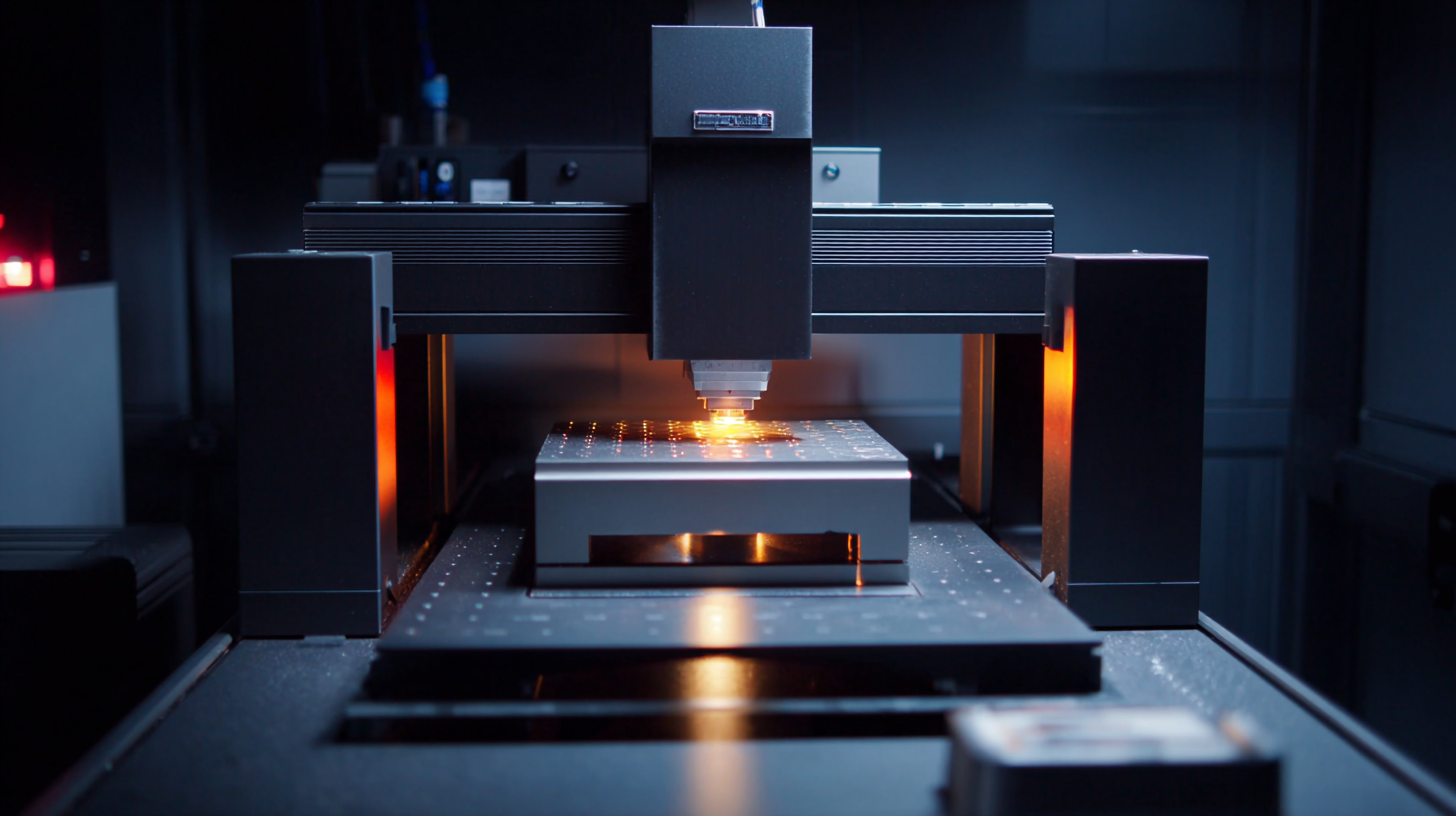

As we venture into the ever-evolving landscape of technology and design, the year 2025 promises to unveil groundbreaking advancements in laser machines. These exceptional tools not only enhance precision and efficiency in various applications but also push the boundaries of creativity in the manufacturing and design sectors. Renowned laser technology expert Dr. Emily Carter emphasizes the significance of these advancements by stating, "The future of design is intricately woven with the capabilities of laser machines, enabling innovations we have yet to imagine."

In exploring the top laser machines of 2025, we witness a fusion of cutting-edge technology and unparalleled craftsmanship. The integration of artificial intelligence and automation in these machines is transforming traditional processes, making it easier for designers and manufacturers to achieve their visions. As industries adapt to rapidly changing market demands, the importance of staying ahead with superior laser technology becomes increasingly crucial.

This outlook not only highlights the technological advancements set to revolutionize the industry but also inspires a new generation of creatives eager to harness the power of laser machines. As we embark on this exploration of the best laser machines of 2025, we anticipate a future filled with limitless possibilities and innovations that will redefine the realms of technology and design.

The landscape of laser technology is rapidly evolving, and by 2025, we can expect remarkable advancements that will redefine the possibilities in various industries. Key innovations anticipated include the integration of artificial intelligence with laser systems, enabling smarter processing capabilities and enhanced precision in applications ranging from manufacturing to medical treatments. The trend toward higher energy efficiencies and more compact designs will also lead to improved performance in laser machines, making them more accessible for small and medium enterprises.

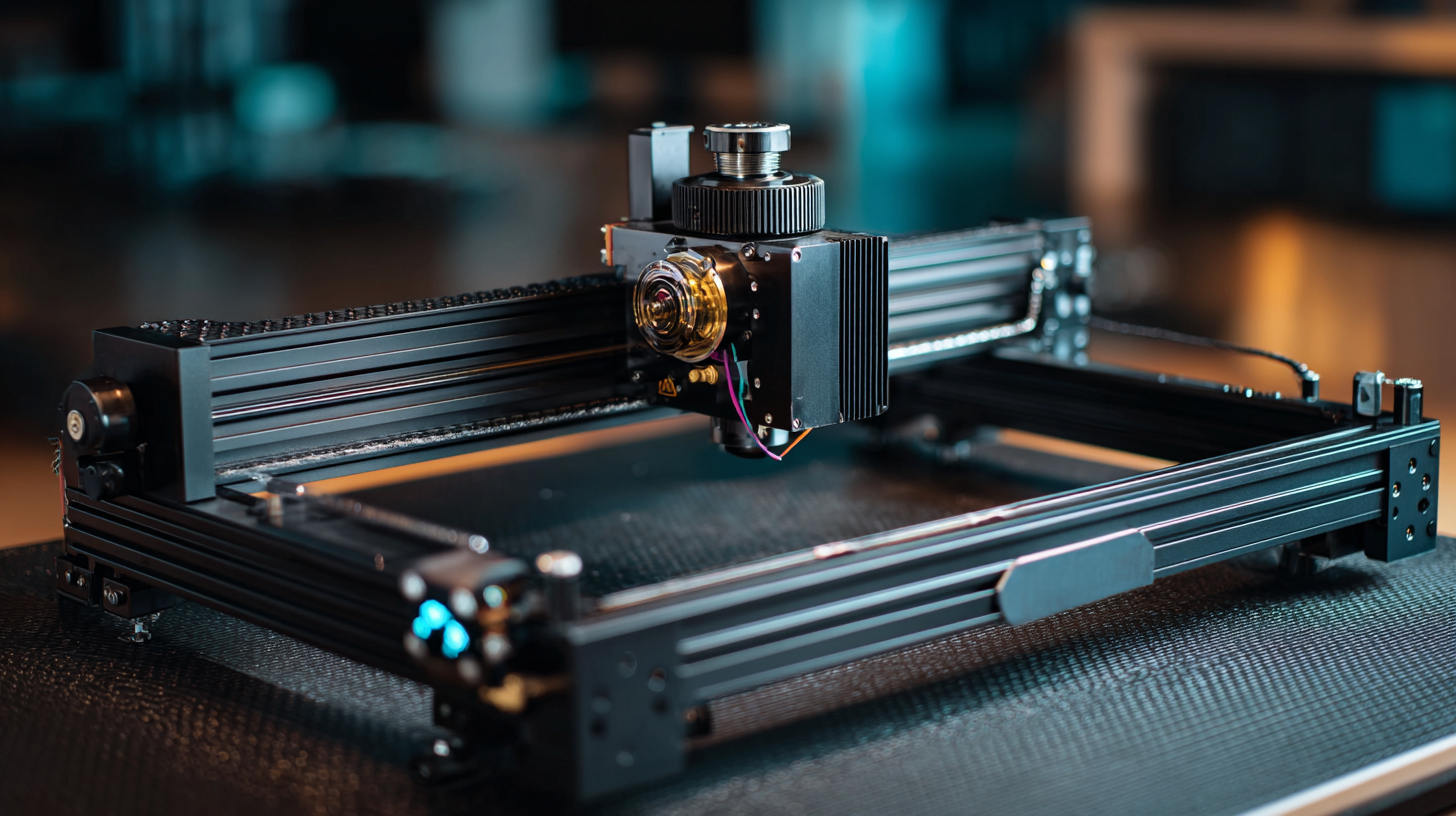

Additionally, the fusion of laser technology with other emerging sectors, such as microelectronics and photonics, will create new avenues for application. The ever-growing demand for rapid prototyping and additive manufacturing will drive the development of versatile laser cutting and engraving machines. As industries seek to streamline operations and reduce waste, the focus will shift towards sustainable solutions, making environmentally friendly laser systems a significant trend to watch. These holistic advancements in laser technology promise not only to enhance efficiencies but also to push the boundaries of creativity and design in 2025 and beyond.

| Machine Type | Max Power (Watts) | Cutting Speed (mm/min) | Materials Supported | Innovative Features |

|---|---|---|---|---|

| CO2 Laser Cutter | 150 | 1200 | Wood, Acrylic, Fabric | Auto-focus, User-friendly Interface |

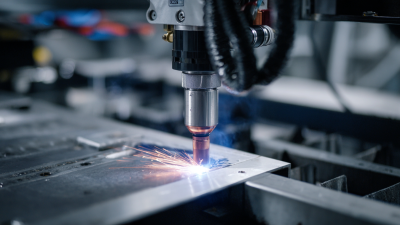

| Fiber Laser Cutter | 200 | 1500 | Metal, Brass, Stainless Steel | High Precision, Low Maintenance |

| Ultrafast Laser Systems | 50 | 2000 | Glass, Ceramics, Semiconductors | Short Pulse Duration, Minimal Heat Affected Zone |

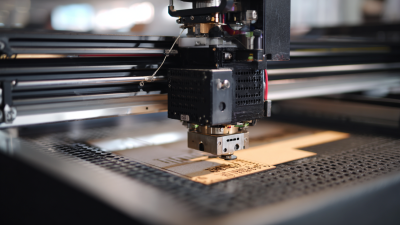

| Laser Engraver | 75 | 800 | Leather, Plastic, Wood | High Speed, Versatile Software |

As we look toward the future of laser technology, the advancements in laser machines for 2025 promise to revolutionize cutting-edge design and manufacturing processes. Key features driving performance in next-gen laser machines include enhancements in power output, precision optics, and automation capabilities. According to a recent report by MarketsandMarkets, the global laser machine market is expected to reach $9.99 billion by 2025, growing at a CAGR of 6.5%. This growth is fueled by the increasing demand for high-speed, high-precision cutting and marking across various industries.

One significant leap forward is the integration of smart technologies, such as AI and IoT, which facilitate real-time monitoring and predictive maintenance. These capabilities not only enhance efficiency but also reduce downtime, allowing for smoother production cycles. The introduction of fiber lasers with higher energy efficiency and lower operating costs additionally sets a new benchmark for performance. Research from Technavio indicates that fiber lasers will dominate the market, projected to hold over 40% share due to their versatility and exceptional cutting quality. Embracing these innovations will be essential for businesses aiming to stay competitive in an increasingly tech-driven landscape.

As we venture into 2025, the landscape of laser cutting technology continues to evolve, finding applications across various industries that exemplify its versatility and efficiency. From automotive to aerospace, the precision offered by modern laser machines enhances design capabilities while streamlining production processes. Industries are leveraging laser technology not only for cutting materials but also for engraving and marking, allowing for intricate designs and personalization that were previously unattainable.

In the fashion and apparel sector, laser cutting is becoming a game-changer. Designers are using advanced laser machines to create intricate patterns and finely detailed textures in fabrics, paving the way for innovative design concepts that capture consumer attention. Tips for designers looking to incorporate laser cutting include starting with prototype designs to explore possibilities, collaborating with laser technology providers for specialized insights, and focusing on material compatibility to achieve the desired aesthetic.

Additionally, the electronics industry is witnessing a significant transformation as laser cutting facilitates the rapid production of circuit boards and housing components, providing both speed and precision. A crucial tip for manufacturers is to invest in training programs that equip operators with the necessary skills to maximize the capabilities of these advanced machines. Adapting to the fast-paced technological advancements will be vital for those wishing to remain competitive in the evolving marketplace.

The global laser machinery market is poised for significant expansion, with projections indicating a remarkable growth trajectory in the coming years. Specifically, the CNC machine market size is expected to increase from $101.22 billion in 2025 to $195.59 billion by 2032, reflecting a compound annual growth rate (CAGR) of 9.9%. This growth is fueled by the increasing demand for precision engineering and the integration of advanced automation technologies in various industries.

Further, specialized sectors within the laser market are also anticipated to experience substantial gains. The fiber laser market is predicted to reach approximately $12.8 billion by 2035, growing at an impressive CAGR of 11.5% from 2025. Moreover, the glass laser engraving machine market forecasts suggest a surge to $1,427.8 million by 2035, with a steady 5.2% CAGR during the same period. These trends illustrate a broader shift toward cutting-edge technology and the adoption of laser solutions, which are becoming integral to modern manufacturing and design processes.

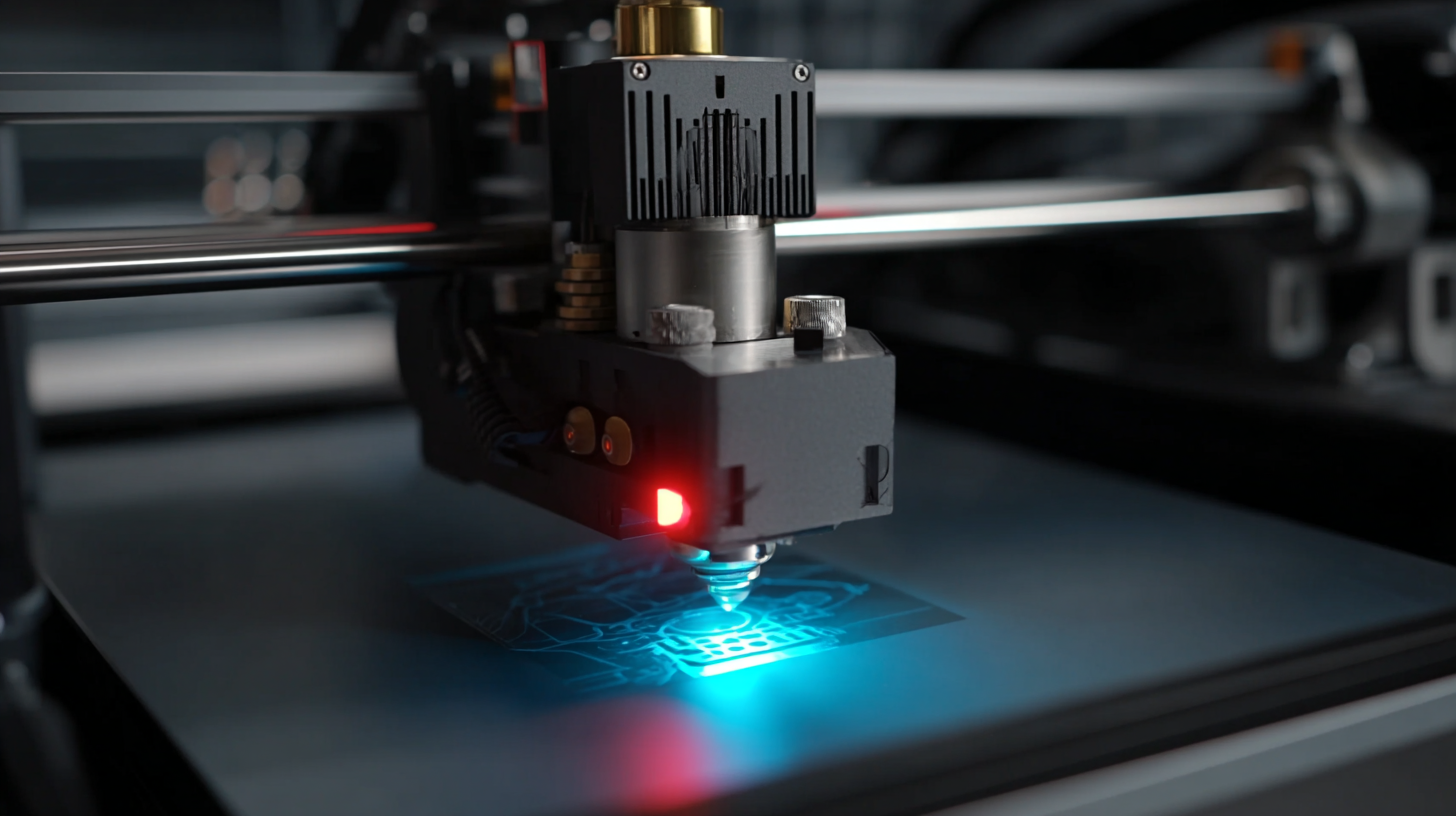

The evolution of laser technology is paving the way for a more sustainable future, particularly in the realm of renewable energy. One notable innovation is laser-induced texturing, which enhances the self-cleaning abilities of solar panels. This technique not only improves the efficiency of solar energy capture but also reduces reliance on chemical cleaning agents, thereby minimizing environmental impacts. According to recent studies, the integration of laser texturing could potentially increase solar panel efficiency by up to 5%, significantly contributing to the overall sustainability of solar technologies.

In addition to its applications in renewable energy, laser technology is having a transformative effect on various industries by facilitating eco-friendly advancements. The emergence of paper holograms constructed from sustainable materials serves as a prime example, enabling sectors such as pharmaceuticals and food to adopt greener packaging solutions. Furthermore, research on laser-induced graphene is opening new avenues in electronics, showcasing the material's remarkable properties that could lead to enhanced performance in devices like solar cells and computer chips. As these innovations continue to develop, they highlight the strategic role of laser technology in driving sustainability across multiple sectors.

This chart illustrates the advancements in laser machines expected in 2025, focusing on critical performance metrics such as power efficiency, material versatility, precision, and sustainability. These innovations reflect a strong emphasis on eco-friendly technology and design.