1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

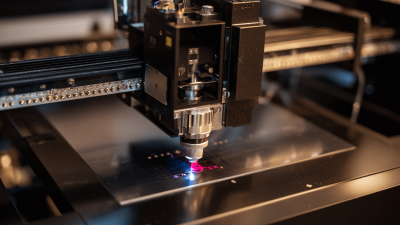

In recent years, the manufacturing industry has witnessed a significant transformation with the advent of the fiber laser marking machine, which is reshaping how products are marked and identified. According to a report by MarketsandMarkets, the global laser marking market is projected to reach $6.97 billion by 2026, growing at a CAGR of 6.2% from 2021 to 2026. This growth is largely driven by the increasing demand for precision and quality in manufacturing processes. Fiber laser marking machines are especially favored for their ability to produce high-contrast, durable marks on a variety of materials ranging from metals to plastics, making them a critical component in sectors such as automotive, aerospace, and electronics. The precision and efficiency offered by these machines not only enhance product traceability but also contribute to reducing waste and improving overall operational efficiency, heralding a new era of manufacturing excellence.

In recent years, the demand for fiber laser marking machines has surged, reshaping the landscape of modern manufacturing. These advanced machines offer unmatched precision and speed, enabling manufacturers to produce high-quality markings on a variety of materials. The rising need for detailed and durable markings, especially in sectors like automotive, aerospace, and electronics, highlights the essential role fiber laser technology plays in meeting industry standards. This increased demand can be attributed to the growing emphasis on product traceability and brand identification, where impeccable marking is crucial.

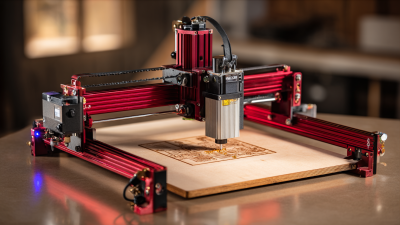

Moreover, with the shift towards automation and smart manufacturing, fiber laser marking machines have become integral to enhancing operational efficiency. Their ability to perform intricate designs without the need for complex setups or extensive downtime has appealed to manufacturers looking to streamline production. As industries continue to evolve, the versatility of fiber laser technology remains a key factor in adapting to market needs, further solidifying its position as a cornerstone in modern manufacturing processes.

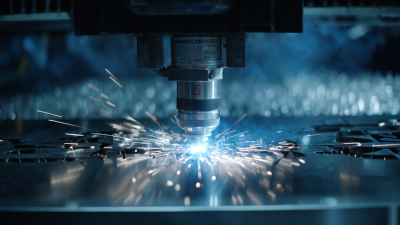

Fiber laser marking technology represents a significant advancement over traditional marking methods, offering numerous key advantages that enhance precision and efficiency in manufacturing. According to a report by MarketsandMarkets, the global fiber laser market is projected to reach $4.6 billion by 2025, indicating a rapid adoption in various industries. One of the primary benefits of fiber laser marking is its high precision and detail, capable of creating intricate designs on a variety of materials, including metals and plastics. This precision is attributed to the short wavelength of fiber lasers, which enables them to produce a smaller focal point compared to traditional CO2 lasers.

Additionally, fiber laser marking machines are known for their speed and efficiency. Research from Allied Market Research shows that fiber laser systems can mark surfaces up to five times faster than conventional methods, drastically reducing production time. This increase in speed not only boosts productivity but also minimizes the wear and tear on machinery, leading to lower maintenance costs. Furthermore, fiber lasers offer greater versatility, allowing manufacturers to switch between different materials and thicknesses without the need for significant recalibrations or prolonged setup times, making them a valuable investment for modern manufacturing processes.

Fiber laser marking machines are transforming the landscape of manufacturing by enhancing precision in product marking. The impact of precision marking is significant, as it not only ensures product quality but also elevates brand value. Accurate markings, which include serial numbers, logos, and intricate designs, help in maintaining high standards of traceability and authenticity. This level of detail reassures customers about the quality of their purchased products, reinforcing their loyalty and enhancing the brand’s reputation in a competitive market.

When considering the implementation of fiber laser marking, manufacturers should keep the following tips in mind: First, choosing the right type of laser for specific materials can greatly improve the quality and efficiency of the marking process. Second, regular maintenance of the laser marking machine ensures consistent performance and longevity, which ultimately contributes to sustained product quality. Last but not least, investing in training for staff can maximize the benefits of this technology, ensuring that the precision marking aligns with the overall manufacturing strategy.

By focusing on precision marking, companies can not only improve their product quality but also leverage this advantage to enhance their brand's value in the eyes of consumers. Product labels that stand out for their clarity and complexity can communicate a brand's commitment to excellence, driving customer preference and strengthening market positioning.

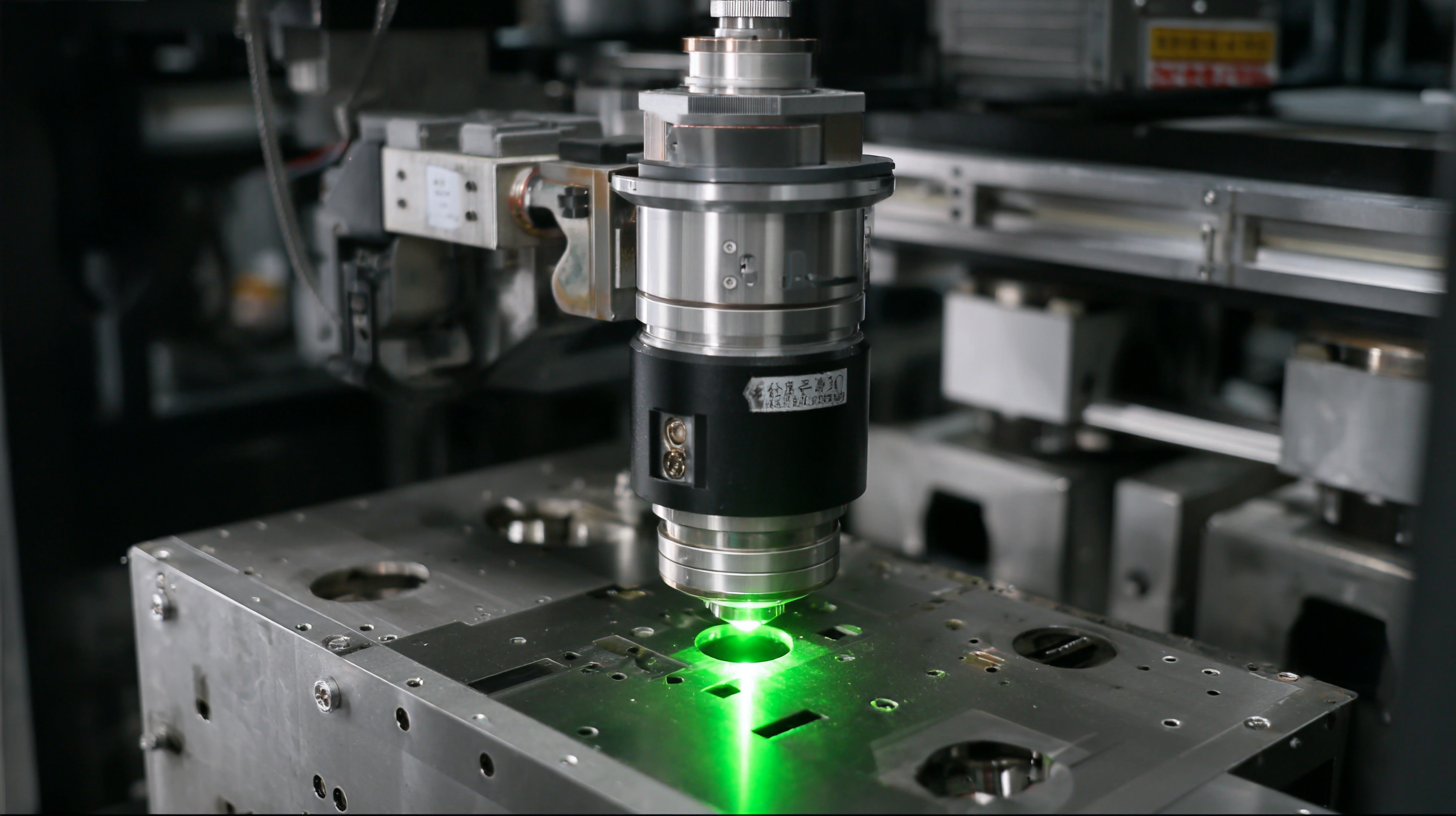

The fiber laser marking machine industry is witnessing significant growth as manufacturers increasingly adopt this advanced technology. Forecasts suggest that the market will continue to expand, driven by the need for high-precision, efficient, and versatile marking solutions. The ability of fiber lasers to produce detailed markings on a variety of materials at high speed makes them ideal for applications in industries such as automotive, aerospace, electronics, and medical devices. As companies prioritize quality and efficiency, the demand for fiber laser marking machines is projected to rise markedly over the next few years.

**Tips for Choosing the Right Fiber Laser Marking Machine:**

When selecting a fiber laser marking machine, consider factors such as the type of materials you will be marking, production speed requirements, and the level of detail needed in your markings. It's also essential to evaluate the machine's power and wavelength compatibility with your application. Additionally, investing in a model with user-friendly software can enhance your operational efficiency and ease the learning curve for your team.

As the industry grows, staying informed about technological advancements is crucial. Look out for features like improved marking speeds, enhanced software capabilities, and integrated automation options. These innovations can significantly improve your manufacturing processes and set you ahead of the competition.

| Year | Market Size (Million USD) | Growth Rate (%) | Key Application Areas |

|---|---|---|---|

| 2021 | 350 | 5.0 | Automotive, Electronics |

| 2022 | 375 | 7.1 | Aerospace, Medical |

| 2023 | 400 | 6.7 | Consumer Goods, Packaging |

| 2024 | 430 | 7.5 | Construction, Metalworking |

| 2025 | 460 | 6.9 | Telecommunications, Defense |

Fiber laser marking machines are transforming manufacturing across various sectors with their unparalleled precision and efficiency. From automotive to electronics, businesses are discovering the advantages of using these advanced technologies. For instance, in the automotive industry, companies have reported significant improvements in traceability and quality assurance by implementing fiber laser marking for parts identification. This level of accuracy not only enhances production processes but also minimizes errors, ultimately leading to greater customer satisfaction.

In the medical device sector, fiber laser marking is utilized to ensure compliance with stringent regulatory standards. One case study revealed that a manufacturer significantly reduced its inspection time by employing laser marking, which provides permanent and legible markings without affecting the integrity of the devices. This innovation not only streamlined operations but also reinforced the importance of safety and reliability in medical products.

Tips: When considering fiber laser marking for your production line, evaluate the specific requirements of your industry to choose the appropriate machine. Additionally, invest in training for your operators to maximize the benefits of this technology and ensure seamless integration into your existing processes. Regular maintenance of the laser machines can also enhance their lifespan and performance, allowing for uninterrupted production.