1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

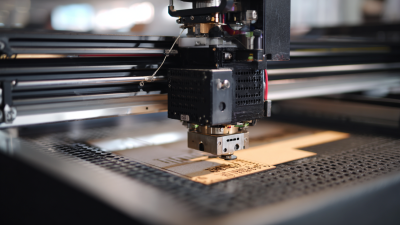

In today’s competitive market, a commercial laser engraver can elevate your business. These machines offer precision and versatility for various materials. Imagine engraving unique designs on wood, glass, or metal. The detail and quality can attract customers and set your products apart.

Investing in a commercial laser engraver may seem costly initially. However, the long-term benefits often justify the expense. It can reduce labor costs and increase production speed. High-quality engravings ensure customer satisfaction and repeat business.

Yet, it’s essential to consider your specific needs. Do you have enough space for this equipment? Are you ready to learn the required skills? Reflecting on these questions can guide your decision. A commercial laser engraver may transform your operations, but it requires commitment and thoughtful planning.

A commercial laser engraver can transform your business operations. It enables precise and intricate designs on various materials. From metal to wood, the versatility is impressive. This tool enhances product offerings. Customers see the value in customized items. Personalized gifts or unique branding can boost sales. The initial investment may seem high, but the returns can be substantial.

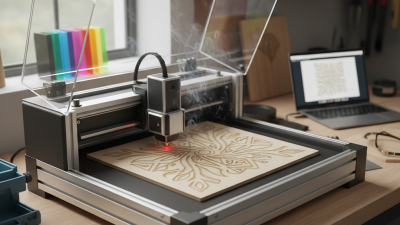

Operating a laser engraver requires skill and training. Employees need time to adapt to this technology. Mistakes in the engraving process can waste materials and time. However, with practice, these challenges become manageable. The opportunity for creativity increases significantly. Businesses can stand out in competitive markets.

Maintenance is important for optimal performance. Regular checks can prevent costly failures. Some users may overlook this aspect. A lack of maintenance can lead to frustration. Investing in upkeep is part of the journey. Ultimately, embracing a commercial laser engraver brings both challenges and benefits.

Commercial laser engravers serve varied applications across industries.

In manufacturing, they mark products for easier identification. This includes engraving barcodes or serial numbers on metal parts.

Such clarity helps streamline inventory management and keeps operations efficient.

Misplaced products can cause delays, so precision is key.

In the promotional industry, businesses use laser engraving for custom gifts. Items like pens or plaques can bear unique designs or logos.

Each engraved piece can attract clients and boost brand visibility.

Personalization adds a special touch that standard print cannot match. However, the challenge lies in ensuring consistent quality across batches.

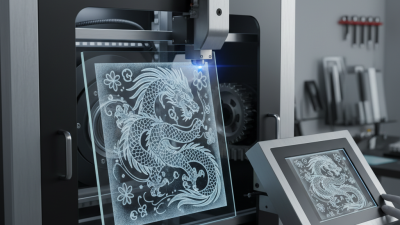

The jewelry industry also sees laser engraving as a vital tool. It allows for intricate designs on delicate pieces.

Names or special dates can be etched into items, creating memorable gifts.

But, intricate work may lead to errors if operators are not skilled. Regular training is crucial in maintaining high standards and preventing costly mistakes.

Investing in a commercial laser engraver can significantly enhance your business's cost efficiency. According to industry reports, businesses that adopt this technology can reduce engraving costs by up to 40%. This reduction stems from lower material waste and higher precision in engraving processes. The ability to quickly switch between different materials also translates to less downtime.

The initial investment might seem daunting. However, the return on investment (ROI) typically materializes within 12 to 24 months. Studies show that companies report a 150% increase in productivity after integrating laser engraving. This improvement can drive greater revenue without the need for additional labor. Moreover, flexible pricing strategies become possible, allowing companies to cater to various market segments.

Despite the benefits, there are challenges. The learning curve for operating laser engravers can be steep. Employees may require training to maximize the equipment's potential. Initial setup and maintenance can also pose obstacles. Businesses must weigh these considerations against potential gains. Understanding the financial impact is crucial.

This chart illustrates the financial impact of using commercial laser engravers in terms of initial investment, operating costs, revenue growth, and project turnaround time, providing valuable insights into potential cost efficiency and return on investment (ROI).

The world of laser engraving offers unmatched precision and quality, essential for today's businesses. Laser engravers can etch intricate designs on various materials, including wood, metal, and glass. This capability elevates product standards, allowing brands to stand out. Details matter. Customers appreciate the finesse of finely engraved products; it reflects quality.

However, achieving this level of precision can be a double-edged sword. Not every attempt will yield perfect results. Some designs may appear inconsistent or flawed. It’s crucial for businesses to regularly evaluate their processes. This creates avenues for improvement and ensures a commitment to quality over time. Careful calibration of machines and attentive monitoring of settings can significantly reduce errors.

Moreover, laser engraving isn't just about appearance. It directly impacts customer perception. A well-finished product can boost a brand's reputation. But when mistakes occur, they can undermine trust. Businesses must be vigilant and strive for continuous enhancement, recognizing that the path to perfection requires ongoing attention to detail and a willingness to learn from setbacks.

| Feature | Benefit | Application | Material Compatibility |

|---|---|---|---|

| Precision Cutting | Achieves intricate designs and fine details | Customized products, signage, and awards | Wood, acrylic, metal |

| Speed of Production | Faster turnaround times for orders | High-volume manufacturing | Plastic, glass, leather |

| Durability of Engraving | Long-lasting markings that withstand wear | Industrial parts, tools, and equipment | Metal, ceramics, coated surfaces |

| Versatility | Allows for a wide range of customization options | Personalized gifts, promotional items | Wood, glass, fabric |

| Eco-Friendly Process | Produces minimal waste and uses less energy | Sustainable branding solutions | Biodegradable materials, reclaimed wood |

The demand for laser engraving technologies is on the rise. Businesses are increasingly choosing laser engravers to enhance their products. This trend stems from the need for precision and quality in customization. Companies want to offer unique items that attract customers. Personalization helps brands stand out in a crowded market.

More industries are embracing this technology. From jewelry to promotional items, laser engraving is versatile. It allows for intricate designs and faster production times. Companies can respond quickly to customer preferences. However, adopting this technology requires investment. Businesses must weigh the costs and benefits. Training is also crucial for staff to use these machines effectively.

As laser engraving grows in popularity, some challenges arise. Maintenance can be time-consuming and sometimes frustrating. Not all designs translate well onto various materials. Businesses should be prepared for trial and error. The learning curve may deter some, but the potential rewards are significant. Embracing the challenge may lead to innovative offerings and increased sales.