1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

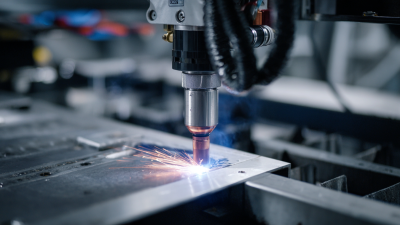

Choosing the right laser welding machine is crucial for any fabrication business. The market for laser welding technology is projected to grow significantly. Reports indicate that by 2025, the industry could reach a value of over $2 billion. This growth reflects the increasing adoption of automation and advanced manufacturing techniques.

When selecting a laser welding machine, consider the material type. Different machines excel with different metals. For instance, stainless steel may require a higher power output than aluminum. Inaccurate selection leads to inefficiencies and higher costs. The right machine enhances precision and reduces waste.

Budget constraints are also vital. While high-end models offer advanced features, they may not always be necessary. Sometimes, a mid-range option can provide adequate performance. Assessing your specific needs helps avoid overspending. Choosing wisely ensures that the investment delivers long-term rewards.

When choosing the right laser welding machine, understanding the types available is crucial. There are three main types: solid-state, fiber, and CO2 lasers. Each has unique advantages. Solid-state lasers excel in precision, while fiber lasers are known for speed and efficiency. CO2 lasers offer versatility in material applications.

A recent industry report indicates that the fiber laser market is expected to grow by 18% annually through 2025. This growth reflects the increasing demand for automation and high-quality welds in various sectors, including automotive and aerospace. Knowing these trends can help you make an informed decision.

Tips: Consider the materials you'll work with. Fiber lasers are best for metals, while CO2 is ideal for plastics or wood. Analyze your project requirements closely. It’s essential to also think about power settings, as this affects your welding speed and seam quality. Lastly, don’t ignore maintenance needs. Accessibility can vary significantly among models, impacting long-term usability.

Choosing the right laser welding machine can be daunting. There are many factors to consider, depending on your specific needs. Power output is essential. Higher watts allow for thicker materials. However, it might be overkill for thin metals.

Tips: Consider your material thickness. Matching the machine power to your tasks can save costs and energy.

Laser type is another critical element. Continuous wave lasers are ideal for steady welding tasks. Pulsed lasers work better for precision and thin materials. Each type has its strengths and weaknesses. Reflecting on your main applications can guide your choice.

Tips: Assess the types of projects you'll tackle. A machine that handles various tasks may be more versatile, yet could also be harder to master.

Finally, consider the safety features. Laser welding can be hazardous without proper precautions. Look for machines equipped with safety interlocks and protective enclosures. Think about the training required for your team. It's vital to ensure everyone understands the machine's operation.

| Key Factor | Description | Considerations |

|---|---|---|

| Laser Type | Different types of lasers (Fiber, CO2, Diode) are suited for varying materials and thicknesses. | Assess the materials you will work with and their thickness. |

| Welding Speed | The speed at which the machine can weld significantly impacts overall productivity. | Determine your production volume and required welding speed. |

| Power Rating | Higher power ratings allow for welding thicker materials but may not be necessary for all applications. | Evaluate the thickness of materials you will weld to choose the right power. |

| Cost | Budget considerations can heavily influence the choice of machine. | Balance between upfront costs and long-term operational efficiency. |

| Ease of Use | User-friendly interfaces can reduce training time and improve efficiency. | Check for features like automation and intuitive controls. |

| Maintenance Requirements | Understanding maintenance needs helps prevent downtime and service interruptions. | Review maintenance protocols and availability of service support. |

| Safety Features | Safety should always be a priority when selecting welding equipment. | Look for features like automatic shut-off, protective enclosures, and safety interlocks. |

When selecting a laser welding machine, power requirements are crucial. The power level can significantly impact welding speed and quality. Higher power typically enables deeper penetration and faster processing times. However, excess power can lead to overheating or material distortion. Striking the right balance is essential.

Consider the material types you will weld. Different materials have unique power needs. For instance, stainless steel may require different settings compared to aluminum. Each material’s thickness will also influence the necessary power. Sometimes, you might choose a machine with adjustable power settings for versatility. These features can provide more control during various projects.

Remember to evaluate your working environment. If you have limited space or power supply, it may affect your choice. Not all facilities can support high-powered machines consistently. Additionally, consider the future. As your skills develop, you may need higher power for advanced applications. Reflect on these factors to choose wisely.

When selecting a laser welding machine, focus on material compatibility. Different materials require specific laser settings. For instance, metal types like aluminum and stainless steel respond differently. Each material absorbs energy at varying rates. This affects the laser's effectiveness and weld quality.

Consider the thickness of your materials too. Thicker materials often need higher laser power. Some machines struggle with thicker sections, resulting in weak welds. Testing with sample pieces can save time and frustration. Understand the nuances of welding different metals. Some may warp or discolor easily, while others might require preheating.

It's also important to evaluate your long-term needs. Choosing a machine based solely on current projects may limit future capabilities. Think about additional materials you might work with later. Choosing a versatile machine is key. Reflect on past projects; what worked, what didn't? This insight can guide your decision-making process.

Budgeting for a laser welding machine involves understanding its costs and potential returns. The initial investment can be significant, often ranging from $10,000 to over $100,000. This price varies based on power, automation, and features. A recent industry report indicates that many businesses recover their investment within 2 to 5 years. However, this timeline can shift widely depending on usage and production efficiency.

Operational costs must also be analyzed. Laser machines typically have lower operational costs compared to traditional welding methods. They consume less energy and generate less waste. Still, maintenance can add up over time. A rise in repair costs due to complex technology can be a concern. It's crucial to factor in these variables when estimating your return on investment.

Training personnel adds another layer of budgeting complexity. Skilled operators are essential for maximizing machine capabilities. Investment in training can improve productivity but may have upfront costs. Businesses should also consider the opportunity cost of production downtime during training sessions. Overall, detailed analysis and careful planning can help navigate the intricacies of budgeting for a laser welding machine.