1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

When it comes to identifying the right dot peen marking machine for your specific requirements, understanding the various options available can be a daunting task. These machines are essential tools in various industries, providing reliable and precise marking solutions for metals, plastics, and other materials. The versatility and durability of a dot peen marking machine make it an invaluable asset, whether for high-volume production or low-volume, specialized tasks.

Choosing the perfect machine involves considering several critical factors, including the type of material you will be marking, the required mark depth and quality, as well as the machine's ease of use and maintenance. By taking the time to evaluate these aspects, you can ensure that the dot peen marking machine you select meets your operational needs efficiently and effectively.

In this guide, we will explore the top ten tips to help you navigate the selection process with confidence. From assessing your marking needs to understanding the technology behind different models, our insights aim to simplify your decision-making and support your quest for the optimal dot peen marking solution.

Dot peen marking technology has gained significant traction in various industries due to its versatility and efficiency in creating permanent markings on a wide range of materials. The process involves using a stylus to create a series of dots on the surface, thus forming alphanumeric characters, logos, or barcodes. According to recent market analysis reports, the global dot peen marking machines market is expected to grow at a CAGR of 5.3% from 2021 to 2026, indicating a robust demand driven by automation and traceability requirements in manufacturing and logistics sectors.

One of the primary applications of dot peen marking is in the automotive and aerospace industries, where durability and legibility of markings are critical. The markings can withstand harsh environmental conditions, including high temperatures and exposure to chemicals, which makes them ideal for identification tags, traceability, and regulatory compliance. A study by the International Journal of Advanced Manufacturing Technology highlights that dot peen markings can last for over a decade without fading, further cementing their utility in long-lasting identification solutions.

Moreover, the flexibility of dot peen marking technology allows it to adapt to different production environments, including high-volume manufacturing lines and smaller workshops. With advancements in software and automation, users can now achieve high precision and speed, increasing productivity without sacrificing quality. A report from MarketsandMarkets indicates that the growing trend of Industry 4.0 and smart manufacturing practices is further propelling the adoption of dot peen marking systems, as companies seek integrated solutions for their marking needs that align with their operational efficiency goals.

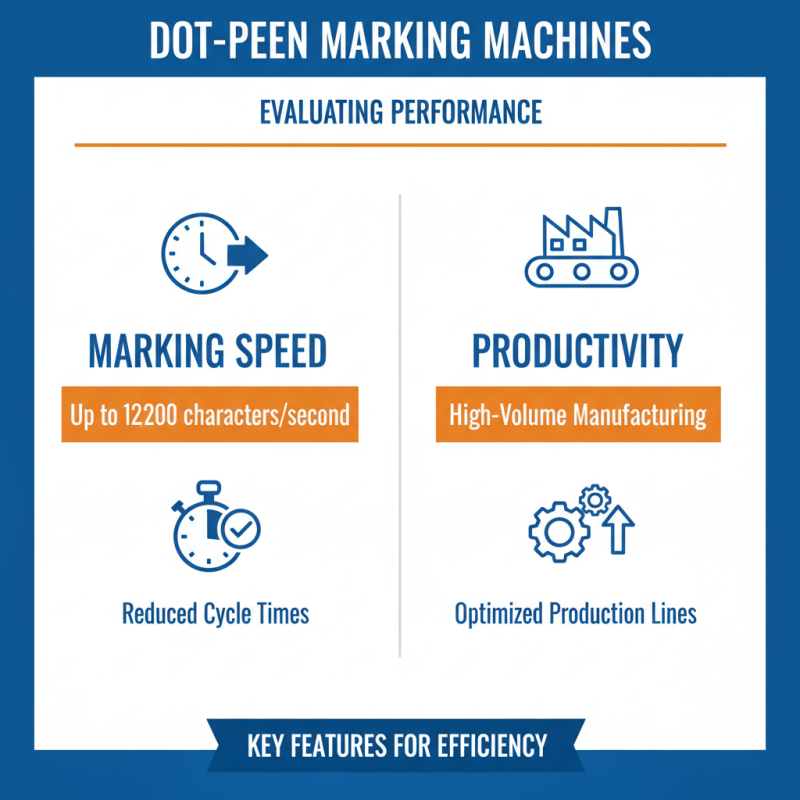

When evaluating marking machines, particularly dot peen machines, it's essential to consider key features that significantly impact performance and productivity. One crucial element is the marking speed, often measured in characters per second. According to industry data, high-performance machines can achieve speeds of up to 1,200 characters per second, drastically reducing cycle times for marking operations in high-volume settings. This efficiency is crucial for manufacturers focused on optimizing production lines and minimizing downtime.

Another important feature is the depth and quality of the mark. The depth can affect the durability of the markings, especially in harsh environments, where resistance to corrosion and wear is necessary. Reports indicate that machines capable of varying the depth of the marking can provide more versatility across different materials, from metals to plastics. Furthermore, the resolution, often measured in dots per inch (DPI), plays a vital role in achieving the desired clarity and detail. A higher DPI ensures that even intricate designs are etched with precision, enhancing both aesthetic appeal and readability.

Finally, the ease of integration and user interface are critical factors for long-term usability. A machine with an intuitive software interface can significantly reduce the learning curve for operators. Data from user satisfaction surveys show that productivity can increase by 20% when operators engage with machines they find easy to use. Additionally, connectivity options, such as USB ports and compatibility with various data input formats, can streamline the workflow, allowing for more seamless operations in diverse manufacturing environments.

When choosing the ideal dot peen marking machine, understanding your production needs and environmental requirements is crucial. According to industry reports, over 60% of manufacturers highlight the importance of adaptability in their marking systems to cater to different materials and production volumes. It is essential to assess the types of materials your business predominantly works with, as dot peen technology can effectively mark metals, plastics, and composites, each requiring different settings and machine capabilities.

Additionally, evaluating the operational environment plays a vital role in selecting the right machine. A report by the Association for Manufacturing Technology indicates that 45% of breakdowns in marking equipment result from unsuitable working conditions such as dust, humidity, and temperature fluctuations. Therefore, consider whether your marking machinery will be used in a controlled environment or a more rugged production floor.

Machines designed to withstand harsh conditions often have enhanced durability features, which can ultimately reduce maintenance costs and bolster productivity. Ensuring that your chosen machine aligns with both your production demands and environmental factors will lead to a seamless marking process that upholds quality and efficiency.

When selecting a dot peen marking machine, it's essential to compare various brands and models to ensure you find the right fit for your application. Different manufacturers offer machines with varying features, capabilities, and price points. For instance, some models may excel in producing clear, deep marks on hard surfaces, while others might focus on speed and efficiency for high-volume production. Additionally, consider the machine’s compatibility with different materials, as well as its adaptability to various marking tasks.

Another critical factor is the technology and ease of use associated with the different machines. Several brands provide user-friendly interfaces, allowing for quick setup and operation, which is crucial for minimizing downtime in a production environment. Moreover, the level of customer support and availability of spare parts also plays a significant role in the long-term usability of the equipment. Comparing these aspects across the available models will help you identify the most reliable option that aligns with your operational needs and budget constraints.

| Criteria | Brand A | Brand B | Brand C |

|---|---|---|---|

| Marking Speed | Up to 150 mm/s | Up to 120 mm/s | Up to 140 mm/s |

| Depth Control | 0.1 - 2 mm | 0.2 - 1.5 mm | 0.1 - 1.8 mm |

| Ease of Use | User-friendly interface | Moderate learning curve | Very user-friendly |

| Power Supply | 220V AC | 110V/220V AC | 240V AC |

| Weight | 35 kg | 30 kg | 32 kg |

| Warranty | 2 years | 1 year | 3 years |

| Price Range | $5,000 - $6,000 | $4,000 - $5,000 | $5,500 - $7,000 |

| Customer Support | 24/7 support | Business hours support | Excellent support |

| Software Compatibility | Windows, Mac | Windows only | Windows, Mac, Linux |

| Applications | Metal, Plastic | Metal only | Metal, Plastic, Wood |

When purchasing a dot peen marking machine, budgeting is a critical aspect that can influence your long-term operational costs. The initial investment for a quality dot peen marking machine can range from a few thousand to tens of thousands of dollars, depending on the machine's capabilities and specifications. According to a recent industry report by MarketsandMarkets, the dot peen marking technology market is projected to grow significantly, with a CAGR of 7.5% from 2022 to 2027. This growth indicates a rising demand for reliable and efficient marking solutions, highlighting the importance of understanding the total cost of ownership.

Maintenance costs should also be a key consideration in your budgeting process. Regular maintenance can add an extra 10-15% to your annual expenditures. Reports suggest that a well-maintained machine can last significantly longer, reducing the need for early replacement. Furthermore, unforeseen breakdowns can lead to costly downtime, impacting your operational efficiency and bottom line. By allocating a budget for both regular check-ups and spare parts, businesses can enhance their marking machine's lifespan and ensure consistent performance, ultimately supporting their production objectives in a competitive market.