1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

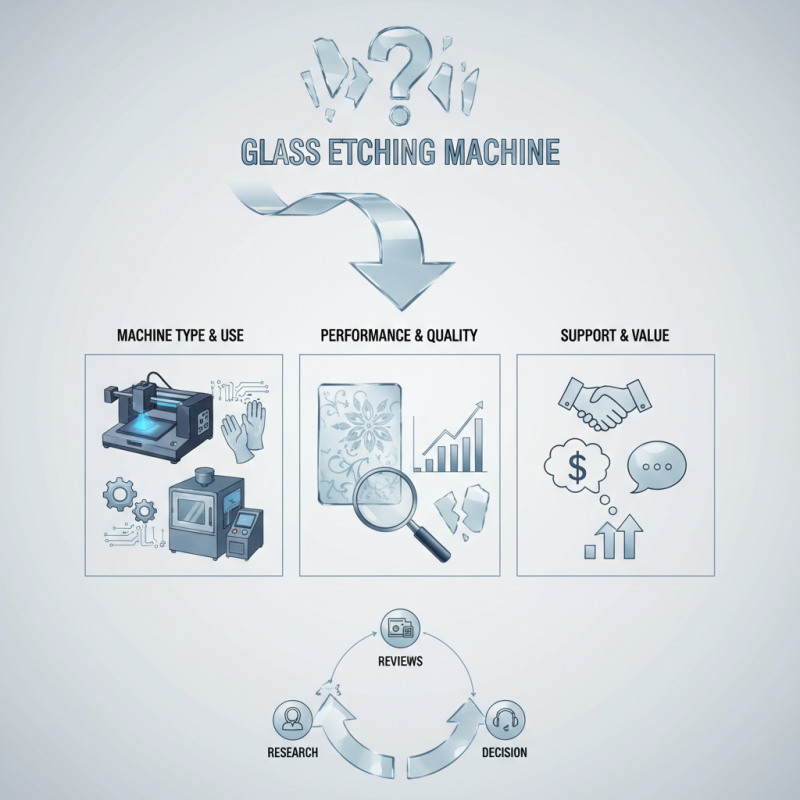

Choosing the right glass etching machine is crucial for quality projects. The global glass market, valued at approximately $240 billion in 2021, is expected to reach over $300 billion by 2027. This growth indicates a rising demand for innovative glassworking techniques. A suitable machine can enhance productivity and creativity in various applications.

Several factors to consider include machine type, ease of use, and versatility. Many glass etching machines offer intricate designs and durable results. However, not all machines are created equal. Some products may lack consistent performance, leading to unsatisfactory outcomes. Customers should weigh their options carefully.

Moreover, the level of customer support can significantly impact your decision. Some manufacturers provide robust guidance, while others fall short. Investing in a reliable machine involves more than just initial costs; it is about long-term satisfaction and project success. Make an informed choice by examining reviews and performance metrics.

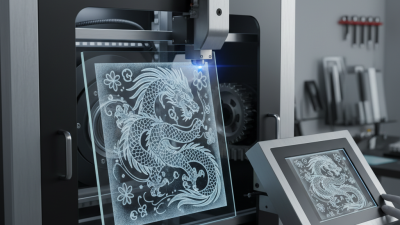

Glass etching is a fascinating art form. It involves creating designs on glass surfaces using various techniques. Among the most popular methods are sandblasting, acid etching, and laser engraving. Each technique offers unique advantages and challenges.

According to a market research report, the global glass etching market is projected to reach $3.5 billion by 2025, growing at a CAGR of 4.2%. This growth indicates a rising interest in personalized glass items, whether for home decor or promotional products. Sandblasting, for instance, can create deep textures and intricate patterns. Yet, it often requires more skill and practice to master.

On the other hand, acid etching is more accessible for beginners. It usually requires less physical effort but demands strict adherence to safety protocols. Laser engraving offers precision and speed, but initial costs can be high. Each method has its pros and cons. Reflecting on your project goals will help in selecting the right technique. Sometimes, the best decision involves trial and error. Understanding these elements can elevate your glass etching projects to a new level.

Choosing the right glass etching machine is crucial for your projects. Look for a machine that offers adjustable speed. This feature allows you to control the depth of your etch. A variety of etching bits is also important. Different bits create different textures and effects. This variety expands your creative options.

Another key feature to consider is ease of use. A user-friendly interface can save time and reduce errors. Ensure that the machine has good safety features as well. Protective gear should be part of your setup. Contaminated glass dust can be harmful. Pay attention to size and portability as well. A lightweight machine can be easier to store and transport.

Lastly, don’t forget about maintenance. Regular upkeep is necessary for longevity. Some machines may require more effort to maintain. This can be a reflection point when making a choice. Weigh the pros and cons carefully. A machine that fits all your needs may not always be the best on paper. Always think about your specific projects and creative goals.

Selecting the right glass etching machine can be a daunting task. A recent industry report indicated that about 45% of users consider precision as a crucial factor. Machines with a focus on accuracy can enhance the quality of your etchings. For instance, a model that boasts a resolution of 1200 DPI produces intricate designs with finer details. This level of precision is essential for professional-grade projects where clarity is paramount.

Moreover, user-friendliness is essential for many hobbyists. An evaluation from a leading market analysis indicated that nearly 35% of buyers prioritize ease of use. Machines with intuitive interfaces are often preferred, particularly for those new to glass etching. Features such as one-touch settings can significantly reduce setup time and improve workflow.

While many machines offer various capabilities, some may fall short in durability. A survey revealed that 30% of users reported issues with machine longevity. An etching machine that excels in performance may struggle to withstand extended usage. Understanding these factors is vital for making an informed choice. Users must consider not just the advertised features, but also real-life experiences to gauge a machine's reliability.

When budgeting for glass etching projects, it’s crucial to understand all potential costs. Consider not just the machine price but also supplies. The cost of etching cream, stencils, and protective gear adds up quickly. You should also account for maintenance expenses. All machines require upkeep, which can vary widely.

Choose a machine that fits your budget but also meets your needs. Sometimes, the cheapest option isn’t the best in the long run. A higher price might mean better durability and quality. Remember, investing in quality tools often saves money over time. It’s generally wiser to spend on a sturdy machine than to replace a flimsy one continuously.

Don’t forget about your skill level. If you are a beginner, a more affordable machine could be wise. However, if you plan to sell your work, consider investing more. Calculate expected profits against your investment. Sometimes, risks can lead to rewarding experiences. Reflect on what truly matters to you in your projects.

When diving into glass etching, safety and maintenance are paramount. Proper protective gear is a must. Always wear goggles to shield your eyes from flying particles. A mask will help prevent inhalation of fine dust. Gloves are necessary to protect your hands from sharp glass edges. It’s easy to overlook these details, yet they are crucial for your health.

Maintaining your equipment ensures its longevity. Regular cleaning prevents dust accumulation. This is often neglected but essential for smooth operation. Check the machine's components for wear and tear. Lubricate moving parts according to guidelines. If vibrations or unusual sounds occur, investigate promptly. Delaying maintenance can lead to bigger and more costly repairs.

Workspaces can also pose hidden risks. Keep your area tidy to avoid tripping hazards. Store chemicals safely and label them clearly. Establish a routine checkup for all equipment before use. Reflection on your safety measures can significantly enhance your crafting experience. Over time, these practices will become second nature, making glass etching safer and more enjoyable.