1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

As businesses increasingly seek precision and efficiency, the choice of the right fiber laser becomes essential. According to a recent report by Market Research Future, the global fiber laser market is projected to reach $6.24 billion by 2026, growing at a CAGR of 10.5%. This statistic highlights the significance of fiber lasers in various applications, including metal cutting and marking.

Experts emphasize the importance of selecting an appropriate fiber laser. Dr. Emily Johnson, a prominent authority in the field, once stated, "Choosing the right fiber laser can dramatically enhance productivity and operational efficiency." The nuances of different models can lead to significant differences in output quality and speed. It’s crucial to assess the specific needs of your business before making a decision.

Some companies, however, overlook key factors such as power output and wavelength. This can result in suboptimal performance and wasted resources. Understanding these criteria is vital for maximizing return on investment. The world of fiber lasers can be complex, and thoughtful consideration is necessary to avoid costly mistakes.

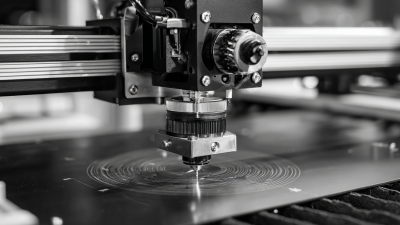

Fiber laser technology has transformed various industries. It provides precision and efficiency in cutting, engraving, and welding materials. According to a market research report, the fiber laser market is projected to reach $4.4 billion by 2025. This growth indicates a rising demand across sectors, from automotive to electronics.

Understanding fiber laser applications is crucial for any business. They excel in processing metals, which is evident in the automotive industry. Reports show that fiber lasers can cut stainless steel up to 30% faster than CO2 lasers. This speed can lead to significant time savings in production. Yet, companies might overlook the learning curve associated with these advanced systems. Operators need training to maximize efficiency.

In addition, fiber lasers are becoming popular in medical device manufacturing. The precision they offer is invaluable in creating intricate designs. However, challenges remain. Some businesses struggle with maintenance and cost management. Regular servicing is needed to maintain performance, impacting the bottom line. It’s essential to reflect on these factors when considering an investment in fiber laser technology.

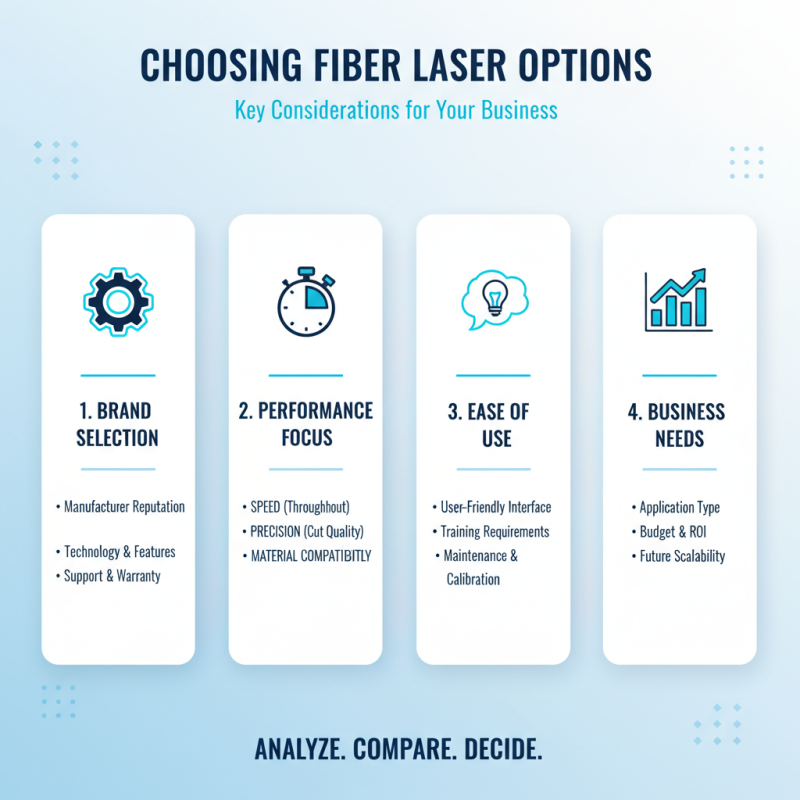

Identifying your business requirements is essential when choosing a fiber laser. Start by assessing your production capacity. Consider how many pieces you need to produce each day. A laser that meets your output goals can save you time and money. Think about the materials you will work with. Different lasers cut or engrave various materials differently. Knowing this helps in selecting compatible technology.

Another critical aspect is your budget. Fiber lasers can vary significantly in cost. Estimating total expenses, including maintenance, is vital. Sometimes, a cheaper model may lead to higher operating costs. Reflect on the skill level of your team. Some systems require advanced training. If your staff lacks experience, this could affect efficiency.

Lastly, analyze your growth potential. Will your business expand in the future? A more versatile laser might be a better investment. It’s not just about current needs; future demands matter too. Consider all these factors carefully. Choosing the right laser should align with both present and future objectives.

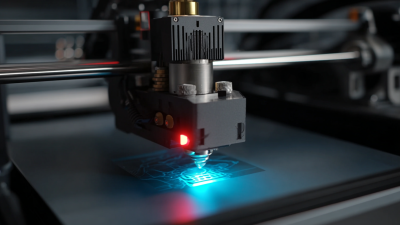

When selecting a fiber laser, efficiency is paramount. Several key features determine this efficiency, including laser power, wavelength, and pulse duration. High power levels can significantly increase cutting speed. Reports indicate that lasers above 2000W offer the best productivity for metal cutting tasks. However, high power also means higher energy costs. Businesses need to weigh these aspects carefully.

Wavelength affects material interaction. A 1070 nm wavelength is ideal for most metals, leading to better absorption and reducing processing time. Research shows that optimizing this feature can enhance efficiency by up to 30%. Pulse duration also plays a critical role. Short pulses improve precision for intricate designs but may not work efficiently for every application. A balanced approach is necessary.

Consider your production volume and material types. Customizing laser settings can lead to optimal results and minimize waste. Some users may overlook this, resulting in inefficiency. Regular maintenance is another aspect. It's easy to neglect routine checks, yet this can lead to performance drops. Efficiency isn’t just about choosing the right laser but also maintaining and adapting it to business needs.

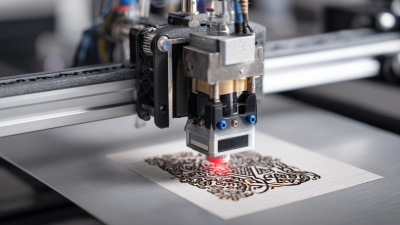

When exploring fiber laser options, brand selection becomes crucial. Different manufacturers provide various technologies and features. Some lasers excel in speed, while others focus on precision. This makes the decision complex. You might find some models more user-friendly, while others require extensive training. It's essential to analyze which factors matter most for your business operations.

Consider the application of your laser. Is it for cutting, engraving, or marking? Different tasks require different specifications. Some machines perform well for metals but struggle with plastics. Understanding the materials you’ll work with can guide your choice. Factor in the maintenance needs too. Some lasers have higher upkeep costs, impacting your budget. A cost-effective model may not always be the best choice.

Visiting trade shows can offer hands-on experience. Testing lasers in person helps gauge performance and usability. However, relying solely on demonstrations might be misleading. Sales pitches often highlight strengths but obscure weaknesses. Ensure to seek user reviews to gain insights into long-term use. Balancing your needs with the options available is necessary. Evaluating multiple brands will give a clearer picture. The right laser can significantly boost productivity, but choosing hastily can lead to regret.

When considering a fiber laser for your business, cost factors play a crucial role. The initial investment can be substantial. These machines often range in price. However, it's essential to look beyond just the sticker price. Think about maintenance costs and operating expenses. A higher-quality fiber laser might save you money in the long run.

Return on investment (ROI) is another critical aspect. Calculate how much you will earn from using the laser. Will it improve your production speed? Faster fabrication might mean more profit. A solid ROI can justify a higher cost upfront. Don't forget to factor in training time and potential downtime. Sometimes, cheaper models may lead to higher overall costs.

Reflect on your specific needs before purchasing. What materials do you usually work with? Some lasers perform better with certain materials. Assess your production volume as well. If you expect to ramp up operations, investing in a more robust machine could pay off. Consider the long-term benefits versus immediate savings. Balancing quality with price is essential for making a wise choice.