1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

Choosing the right laser engraving machine for your business needs is a crucial decision that can significantly impact your operational efficiency and product quality. With a myriad of options available on the market, it can be overwhelming to pinpoint the machine that best fits your specific requirements. Various factors such as material compatibility, engraving speed, precision, and budget constraints must be considered to make an informed choice. This guide aims to provide you with essential insights and practical tips to help you navigate through the features and specifications of different laser engraving machines. Whether you are a seasoned professional looking to upgrade your equipment or a newcomer seeking an ideal starter machine, understanding your business objectives and the technological landscape of laser engraving will set you on the path to success.

Choosing the right laser engraving machine for your business needs is a crucial decision that can significantly impact your operational efficiency and product quality. With a myriad of options available on the market, it can be overwhelming to pinpoint the machine that best fits your specific requirements. Various factors such as material compatibility, engraving speed, precision, and budget constraints must be considered to make an informed choice. This guide aims to provide you with essential insights and practical tips to help you navigate through the features and specifications of different laser engraving machines. Whether you are a seasoned professional looking to upgrade your equipment or a newcomer seeking an ideal starter machine, understanding your business objectives and the technological landscape of laser engraving will set you on the path to success.

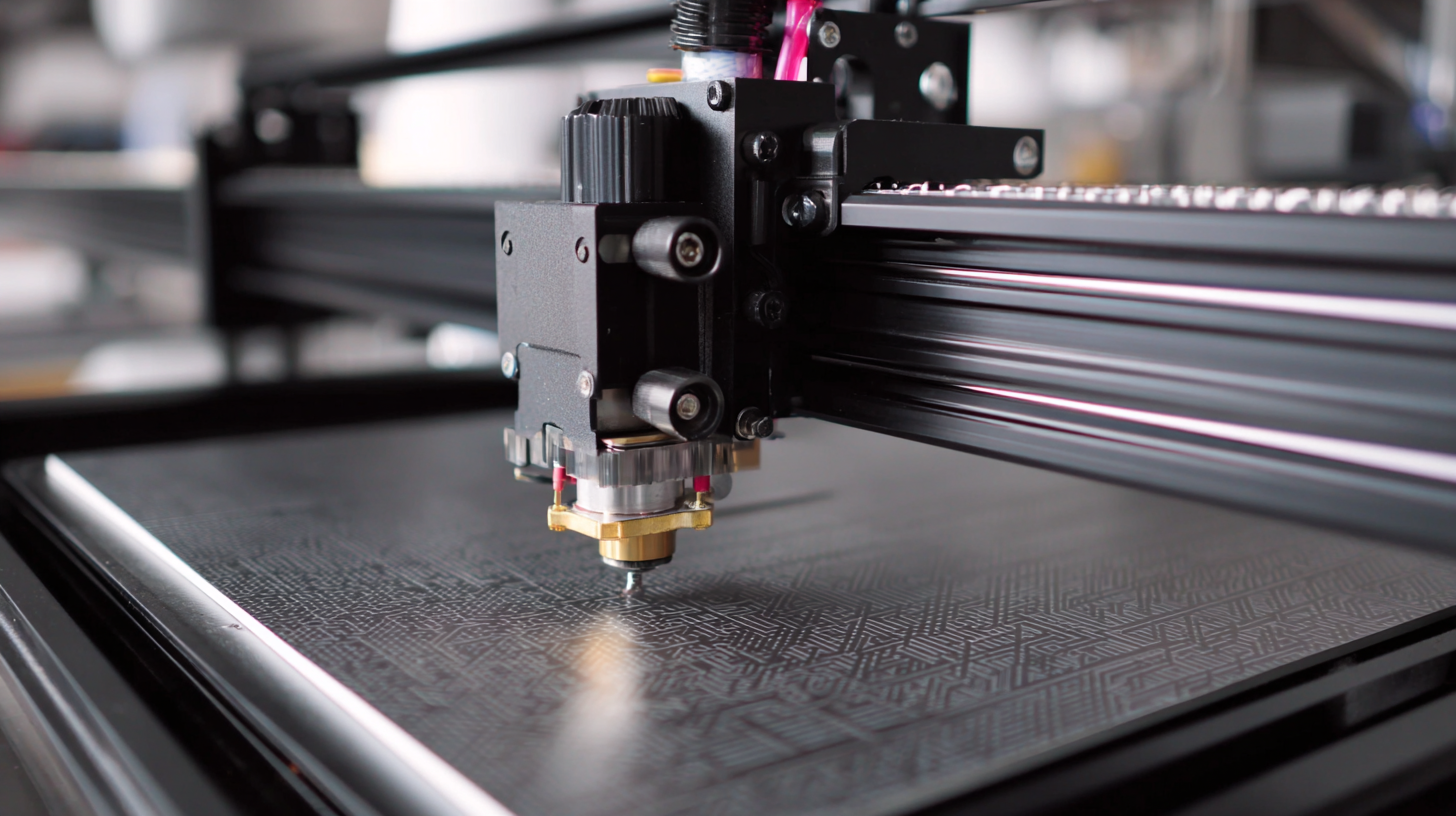

When choosing the right laser engraving machine for your business, understanding your specific engraving needs is crucial. The type of material you plan to work with—be it wood, acrylic, leather, or other non-metallic substances—will heavily influence your decision. Each material behaves differently when subjected to laser engraving; for instance, woods may offer rich textures and colors, while acrylic can provide a sleek and modern finish. A machine suited for diverse materials will offer greater versatility, allowing businesses to expand their product offerings without requiring additional equipment.

Design considerations are equally significant. The complexity of your designs, including detail and size, will determine the type of engraving machine you need. More intricate designs may require a more advanced laser engraving machine with higher precision and speed capabilities. As the non-metal laser engraving machine market continues to grow, projected to reach approximately $575.91 million by 2032, businesses must also account for future growth trends and technological advancements when investing in equipment. Whether opting for stationary machines or portable laser engravers, understanding both material and design requirements will ensure that the selected machine aligns with long-term business objectives.

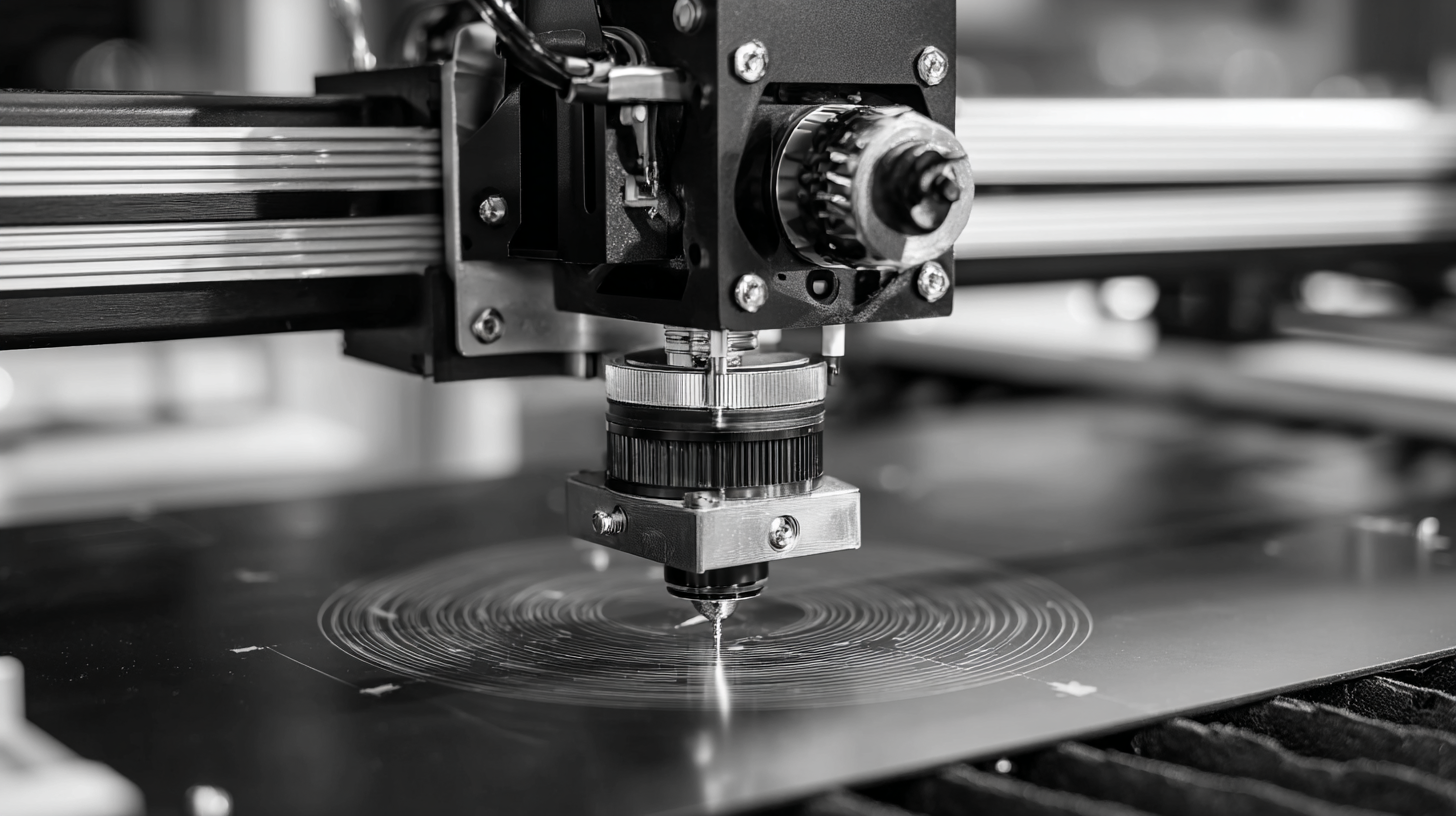

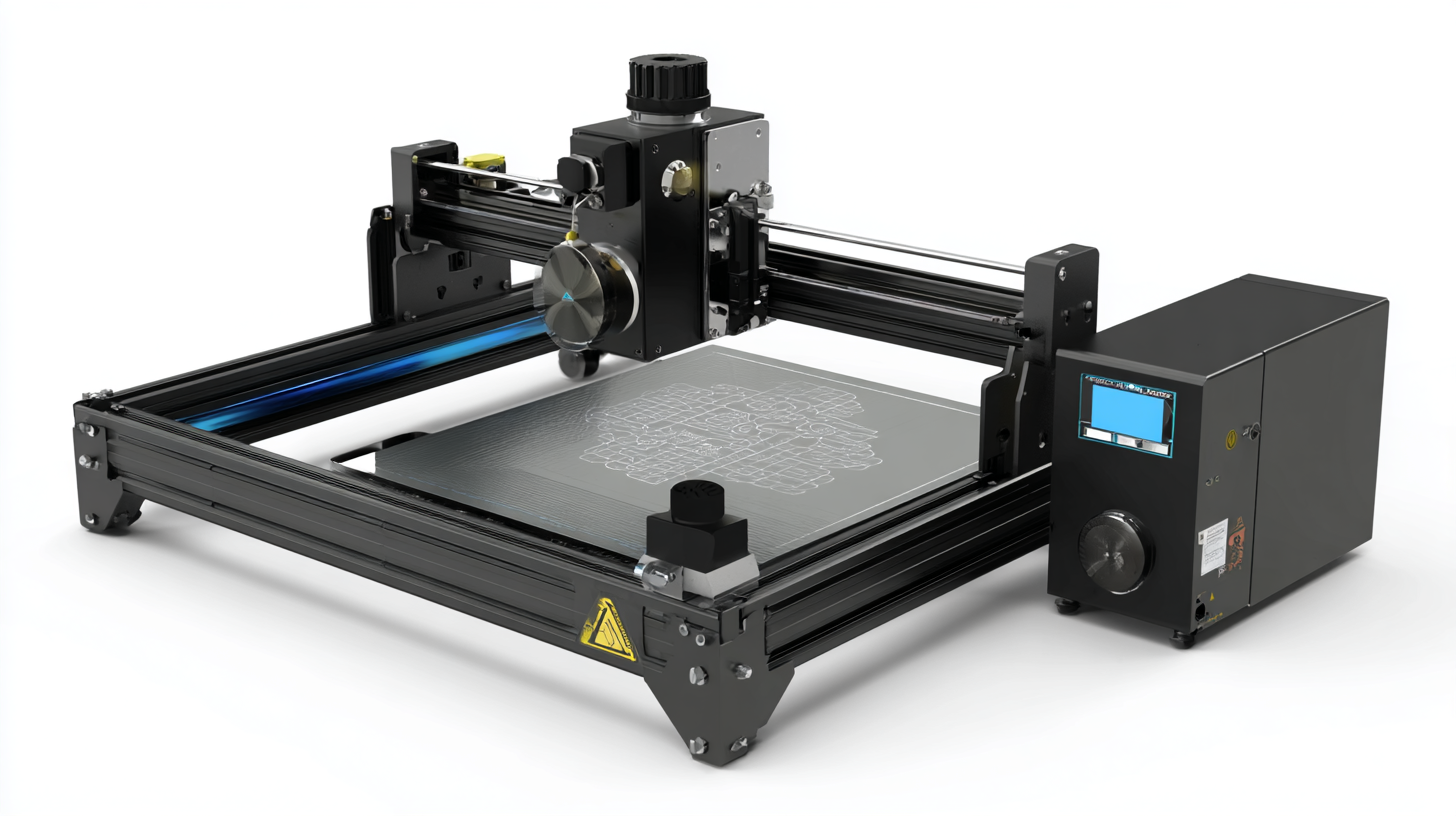

When selecting a laser engraving machine for your business, it is essential to evaluate the different types of machines available on the market. The primary types include Fiber Laser, Diode Laser, Solid-State Laser, CO2 Laser, and UV Laser. Each type has its unique features and applications, making them suitable for various materials and engraving needs. Fiber lasers, for instance, are known for their high speed and efficiency, making them ideal for metal engraving, while CO2 lasers excel at cutting and engraving non-metal materials like wood and acrylic.

As the laser engraving market continues to expand, with a projected sales growth from $658 million in 2023 to over $1.8 billion by 2030, businesses must also consider user-friendliness and safety features when making their choice. Recent advancements have led to the emergence of machines that cater to both beginners and advanced users. Models that integrate intuitive designs and robust safety measures can significantly enhance the user experience, allowing businesses to fully capitalize on the technology's potential. Ultimately, the right machine will depend on your specific business needs, production volume, and the types of materials you intend to work with.

| Machine Type | Power (W) | Engraving Speed (mm/s) | Max Engraving Area (mm) | Material Compatibility | Price Range (USD) |

|---|---|---|---|---|---|

| CO2 Laser Engraver | 40 - 150 | 600 | 300 x 200 | Wood, Acrylic, Glass | $2,000 - $10,000 |

| Fiber Laser Engraver | 20 - 100 | 1200 | 500 x 500 | Metal, Plastic | $5,000 - $25,000 |

| Diode Laser Engraver | 1 - 5 | 200 | 100 x 100 | Wood, Leather | $300 - $1,500 |

| UV Laser Engraver | 10 - 50 | 800 | 200 x 300 | Glass, Acrylic, Wood | $3,000 - $15,000 |

When considering the purchase of a laser engraving machine for your business, evaluating budget and cost-effectiveness is crucial. According to a recent industry report, investing in a high-quality laser engraver can yield a return on investment (ROI) of as much as 200% within the first year of use, depending on the application and market demand. This potential profitability underscores the importance of choosing a machine that not only fits your current operational budget but also aligns with your long-term business strategy.

Tips: Always consider the total cost of ownership when evaluating laser engraving machines. This should include not only the purchase price but also maintenance, operational costs, and the longevity of the equipment. An initial lower-cost option might lead to higher total expenses over time due to frequent repairs or lower efficiency.

Additionally, resources such as market analysis reports indicate that businesses investing in automation and digitization experience operational cost reductions of 20-30%. This highlights the significance of integrating cost-effective machinery that offers advanced features to ensure sustained growth. Choosing the right laser engraver can thus be pivotal for maintaining competitive advantage and optimizing your business operations.

This chart shows the average costs of different types of laser engraving machines based on their capabilities and suitability for various business requirements. Selecting the right machine based on budget can greatly impact the overall cost-effectiveness of your business.

When selecting a laser engraving machine for business needs, focusing on key features such as speed, precision, and software compatibility is essential to ensure optimal performance. Speed is a critical factor; machines that operate at higher speeds can significantly enhance productivity. According to a 2022 industry report, high-speed laser engravers can complete tasks up to 50% faster than their standard counterparts, allowing businesses to meet tight deadlines and increase output.

Precision, measured in terms of the smallest engraving detail achievable, is another vital aspect. A machine with a precision level of 0.01mm can produce intricate designs that appeal to customers, especially in fields like jewelry making and personalized gifts. Reports indicate that businesses utilizing high-precision machines see a 30% increase in customer satisfaction due to the quality of their products.

Tips: When choosing your machine, consider investing in models that offer flexible software compatibility. This flexibility enables you to integrate various design programs, ensuring that you can create and manipulate designs according to customer demands. Additionally, always check for user reviews and testimonials specific to both speed and precision, as real-world performance can vary significantly from manufacturer claims.

When selecting the right laser engraving machine for your business, it's essential to consider maintenance and support options that can ensure the longevity of your investment. Regular maintenance is not only crucial for the optimal performance of the machine but also for minimizing downtime, which can directly impact productivity. Engaging with suppliers who provide comprehensive support can help mitigate potential issues before they escalate. This includes access to technical support, easy availability of replacement parts, and guidance on routine maintenance practices.

Furthermore, exploring generative AI solutions can enhance customer service efficiency in the context of laser engraving. By leveraging AI technologies, businesses can streamline their support processes, offering real-time assistance and personalized interactions. This proactive approach to maintenance and customer support can result in higher satisfaction levels and reduce the burden on human resources. Implementing a strategic blend of advanced technology and regular upkeep will ensure that your laser engraving machine not only meets current needs but adapts to future challenges in the ever-evolving business landscape.