1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

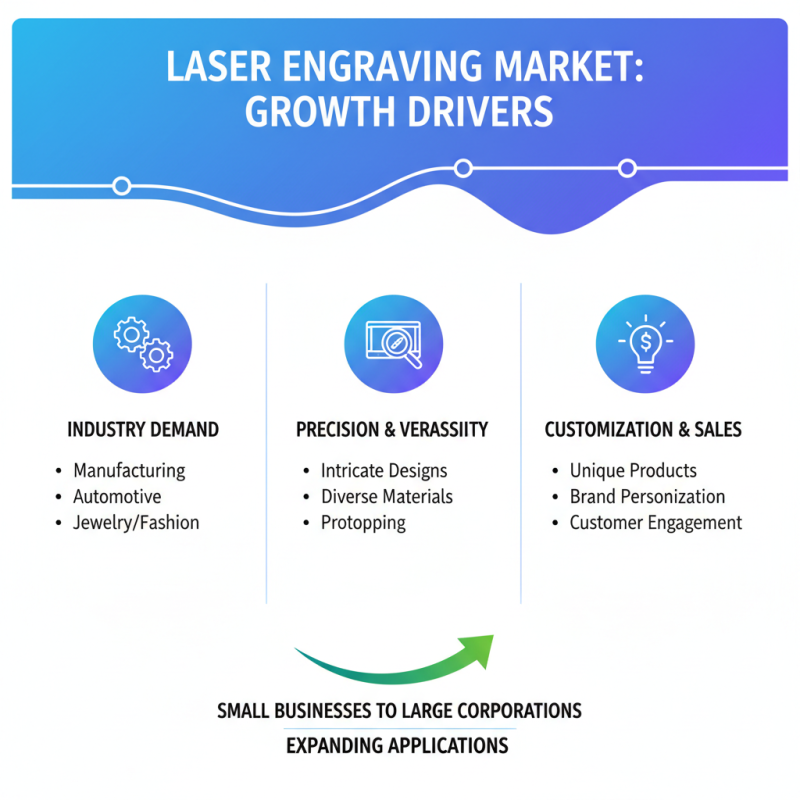

In today’s competitive market, businesses are constantly seeking innovative ways to stand out. The use of a laser engraving machine can be a game-changer. According to the Laser Institute of America, the laser processing industry is expected to grow by 12% annually. This growth highlights the increasing demand for precision and customization in manufacturing.

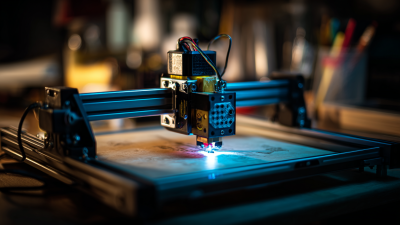

Laser engraving offers versatility. From metal to wood, its application is vast. Small businesses can create unique products, enhancing customer loyalty. However, many still underestimate the potential of laser engraving. Often, companies rely on traditional methods, missing out on efficiency and quality.

Investing in a laser engraving machine can seem daunting. The initial cost may raise concerns. Yet, the long-term benefits often outweigh these worries. Reports indicate that businesses adopting laser technology see a return on investment within two years. A laser engraving machine can lead to increased productivity and reduced waste. These factors are crucial for sustained success in a rapidly evolving marketplace.

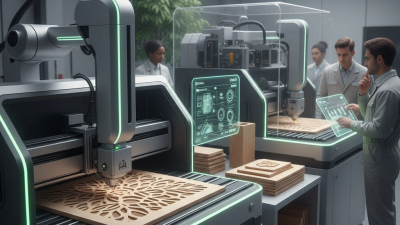

Laser engraving machines are transforming the landscape of modern businesses. They offer precision and versatility that traditional methods can't match. With these machines, you can engrave logos, designs, and intricate patterns on various materials like wood, metal, and glass. This capability allows for personalized products that can attract more customers.

Using laser engraving can significantly reduce production time. While it may take time to learn the technology, the initial learning curve can pay off in efficiency. Businesses should reflect on the initial investment. While costs can be high, the potential for profit and customization often outweighs these concerns. Additionally, laser engraving creates minimal waste, which can lead to lower material costs over time.

However, there are aspects to consider. Maintenance of the machines requires careful attention, and not all designs translate well to laser engraving. Some intricate details may get lost, leading to customer dissatisfaction. It's crucial to test designs before committing to large runs. Overall, the benefits of enhanced customization and efficiency make laser engraving worth exploring for modern businesses.

The decision to invest in a laser engraving machine can significantly impact cost efficiency for businesses. Traditional engraving methods, such as rotary engraving, often involve higher labor costs and longer turnaround times. A report by the International Laser Marketplace states that laser systems can reduce production time by up to 75%. This means businesses can take on more projects without increasing overhead.

Moreover, the cost of materials plays a crucial role. Traditional methods often waste materials due to their cutting techniques. In contrast, laser engraving minimizes waste by precisely cutting through materials. This not only saves money but also supports sustainability efforts. The National Association of Manufacturers estimates that companies adopting laser technology can reduce their material costs by about 20%.

However, the initial investment in laser equipment can be daunting for smaller businesses. The learning curve can be steep, which may lead to inefficiencies. It’s essential to weigh these factors against potential savings. Many small businesses report needing additional training to maximize their return on investment. Balancing the initial costs with long-term benefits is necessary for informed decision-making.

Laser engraving machines are gaining popularity across various industries for their versatility. They can mark, engrave, and cut materials with precision. Reports indicate that the global laser engraving market is projected to grow significantly, reaching USD 5.5 billion by 2026. This trend highlights the increasing demand for such technology in different fields.

In manufacturing, laser engraving is used for product labels and machine parts. The automotive industry employs this technology for engraving VIN numbers, ensuring tamper resistance. Customization is a growing trend; studies show that 70% of consumers prefer personalized products. Jewelry makers often turn to laser engraving for intricate designs, giving their creations a unique touch. Unfortunately, some businesses overlook training on this technology. Missteps in settings can lead to production errors.

Crafting and signage industries benefit from laser engraving as well. Signs made with this technique can last much longer than traditional options. Companies also use lasers for cutting materials like wood and acrylic, allowing for complex designs. As industries adapt, the challenge remains—how to keep up with fast-paced technological developments. Companies often invest significant resources without fully understanding their needs. Adjustments in parameters can lead to waste, which is an area ripe for improvement.

Laser engraving machines are transforming the way businesses personalize products. This technology allows for detailed designs on various materials. Customers are seeking unique items that reflect their individuality. With laser engraving, businesses can meet these needs effectively.

Offering customized products enhances customer experience. Imagine a customer choosing a gift with a personal touch. Their excitement grows as they see their name beautifully engraved. This not only attracts new customers but also boosts loyalty among existing ones.

Tips: Start with simple designs. Test the engraving on scrap materials first. This will help refine techniques and avoid costly mistakes. Remember, not every design will be perfect on the first try. Embrace imperfections as learning moments.

Investing in a laser engraving machine could change your business model. It can allow for flexibility in product offerings. But, do consider space and budget constraints. Choose the right machine that fits your needs without stretching resources too thin.

The laser engraving market is witnessing significant growth. Increasing demand in various industries drives this trend. Small businesses and large corporations alike are turning to laser technology for its precision and versatility. Customization options are expanding, allowing for unique designs that attract customers’ attention.

Future trends show that sustainability will play a pivotal role. Eco-friendly materials are gaining popularity. Companies are searching for ways to minimize waste in their engraving processes. Also, advancements in software will simplify operations. Users may sometimes find it challenging to keep up with rapid changes. Training will be essential for adapting to new technologies.

Artificial intelligence integration is also on the horizon. It can optimize engraving patterns, saving time and resources. However, businesses may grapple with the initial investment and learning curve. Careful planning is crucial to ensure a smooth transition. Embracing these developments might lead to significant advantages in the competitive marketplace.