1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

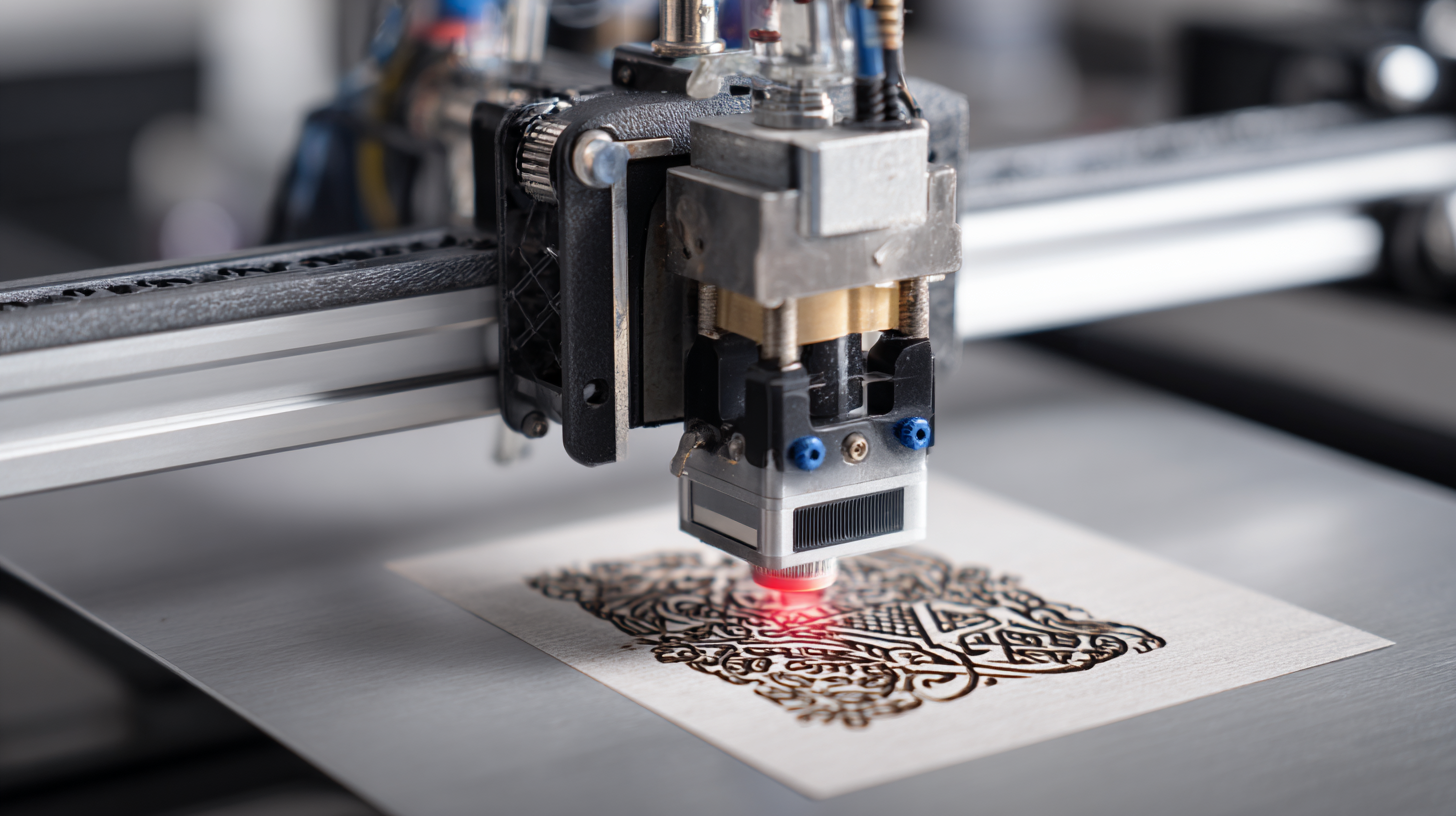

Selecting the best laser engraving machine for your specific needs can significantly impact the quality of your projects and your overall productivity. According to a recent report by MarketsandMarkets, the global laser engraving market is expected to reach $5.12 billion by 2024, growing at a CAGR of 5.22%. This growth reflects a rising demand for personalized products and industrial applications across various sectors, including automotive, electronics, and jewelry. As more businesses and hobbyists explore the versatility of laser engraving, the importance of choosing the right machine becomes paramount. Factors such as material compatibility, power, and engraving speed play critical roles in determining which machine will best suit your requirements. This guide aims to provide insights into how to identify the features that are essential for your projects, ensuring you invest in the best laser engraving machine tailored to your needs.

When selecting a laser engraving machine, understanding your specific engraving needs is paramount. Different applications require distinct capabilities: for instance, industrial engraving often demands machines with higher power outputs and faster speeds, while art and craft projects may benefit from machines that support intricate designs and a variety of materials. According to a market study by Grand View Research, the global laser engraving market is projected to reach USD 4.85 billion by 2025, emphasizing the growing demand for tailored engraving solutions across diverse sectors. This reflects the necessity of aligning your machine choice with your intended uses, whether that be for personalization, mass production, or artistic expression.

Moreover, the materials you plan to engrave significantly influence your machine selection. Materials such as wood, glass, metal, and acrylic require different laser wavelengths and power settings. A report by Research and Markets indicates that CO2 lasers dominate the engraving market due to their versatility in handling organic materials and plastics, making them ideal for hobbyists and small businesses. Conversely, fiber lasers are preferred for engraving metals and are expected to rise in market share as the demand for metal engraving applications grows. Therefore, assessing your material requirements will provide vital insights into which laser engraving machine best suits your specific needs and applications.

| Feature | Description | Ideal Applications | Price Range |

|---|---|---|---|

| Power | Measured in watts, indicates the engraving speed and material compatibility. | Wood, Acrylic, Glass, Metal | $200 - $5000 |

| Engraving Area | Size of the workspace available for engraving projects. | Signs, Awards, Personal Gifts | $300 - $4000 |

| Software Compatibility | Support for CAD or design software used for engraving files. | Custom Designs, Prototyping | $150 - $2000 |

| Portability | Weight and design that allow easy transport and setup. | On-Site Engraving, Events | $250 - $3500 |

| Maintenance | Ease of cleaning and replacement parts availability. | Long-Term Use, Production | $100 - $1000 (yearly cost) |

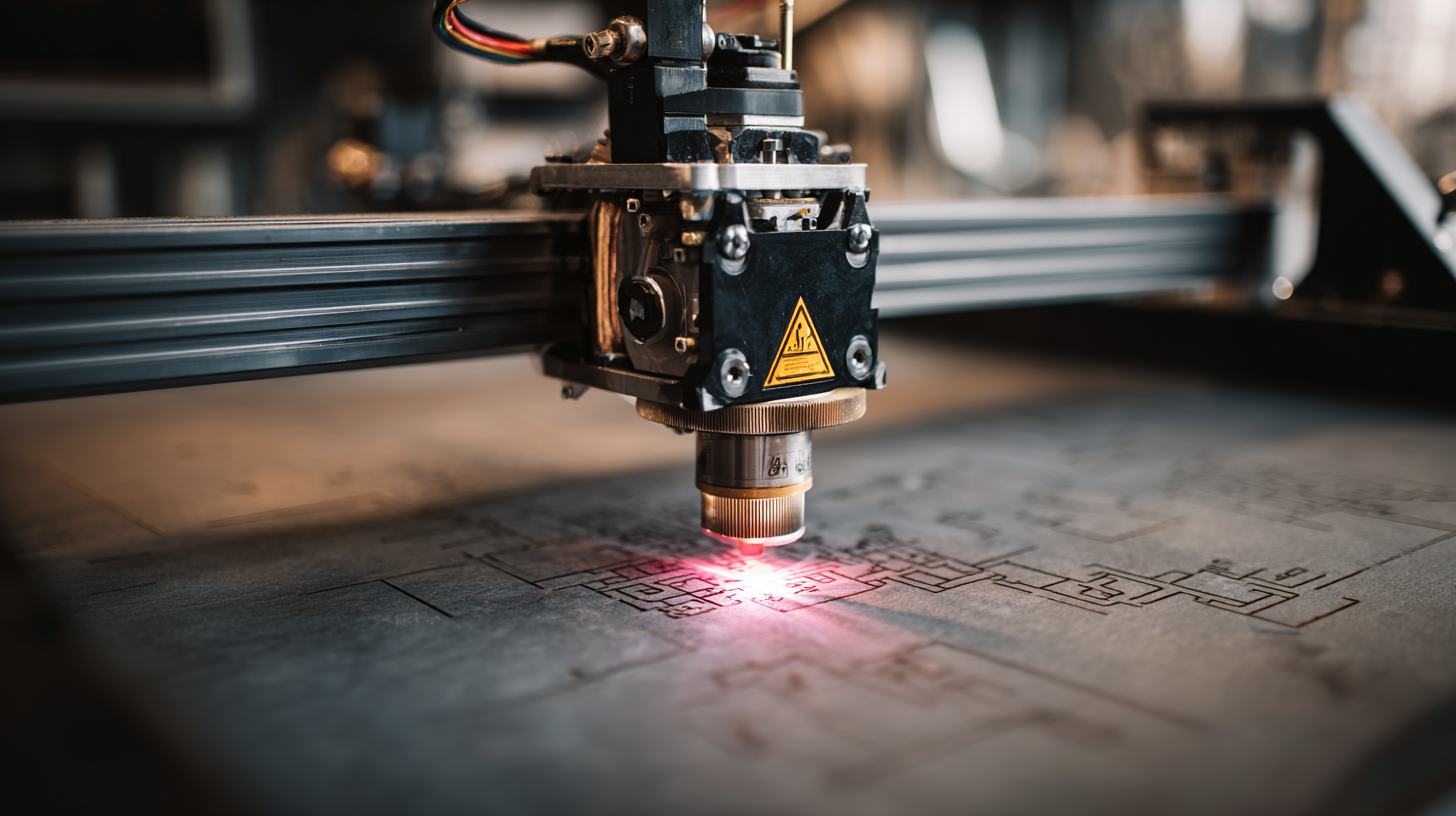

When choosing a laser engraving machine, several key features should be considered to ensure it meets your specific needs. First, the type of laser technology, such as CO2 or fiber lasers, plays a crucial role. CO2 lasers are ideal for engraving non-metal materials like wood, acrylic, and glass, while fiber lasers excel at metal engraving. Understanding the materials you will be working with can guide you to the right type of laser.

Another essential feature is the machine's power and speed. Higher wattage lasers generally offer deeper cuts and faster engraving speeds, making them suitable for larger projects or higher volume production. The size of the engraving area also matters; if you plan to work on larger items, choose a machine with a bigger workspace. Additionally, consider the machine's software compatibility and ease of use, as this will affect your workflow and efficiency. Together, these features will help you select the best laser engraving machine that aligns with your creative and business objectives.

When evaluating budget and cost-effectiveness for your laser engraving machine purchase, it is crucial to assess your specific needs and how they align with potential expenses. Begin by determining the types of materials you intend to engrave and the scale of your projects. This initial evaluation can significantly impact the price range of the machine you will need. Cheap machines may save upfront costs, but they often lack durability and precision, leading to potential long-term expenses due to repairs or replacements.

Next, consider the total cost of ownership, which includes not only the purchase price but also operational costs such as maintenance, power consumption, and replacement parts. A more expensive, high-quality machine may offer better efficiency and lower operational costs over time, making it a cost-effective choice in the long run. Additionally, factor in potential revenue if you plan to start a business; a reliable and efficient machine can yield better profits, justifying a higher initial investment. By thoroughly evaluating these aspects, you can make an informed decision that balances your budget with the machine's overall value.

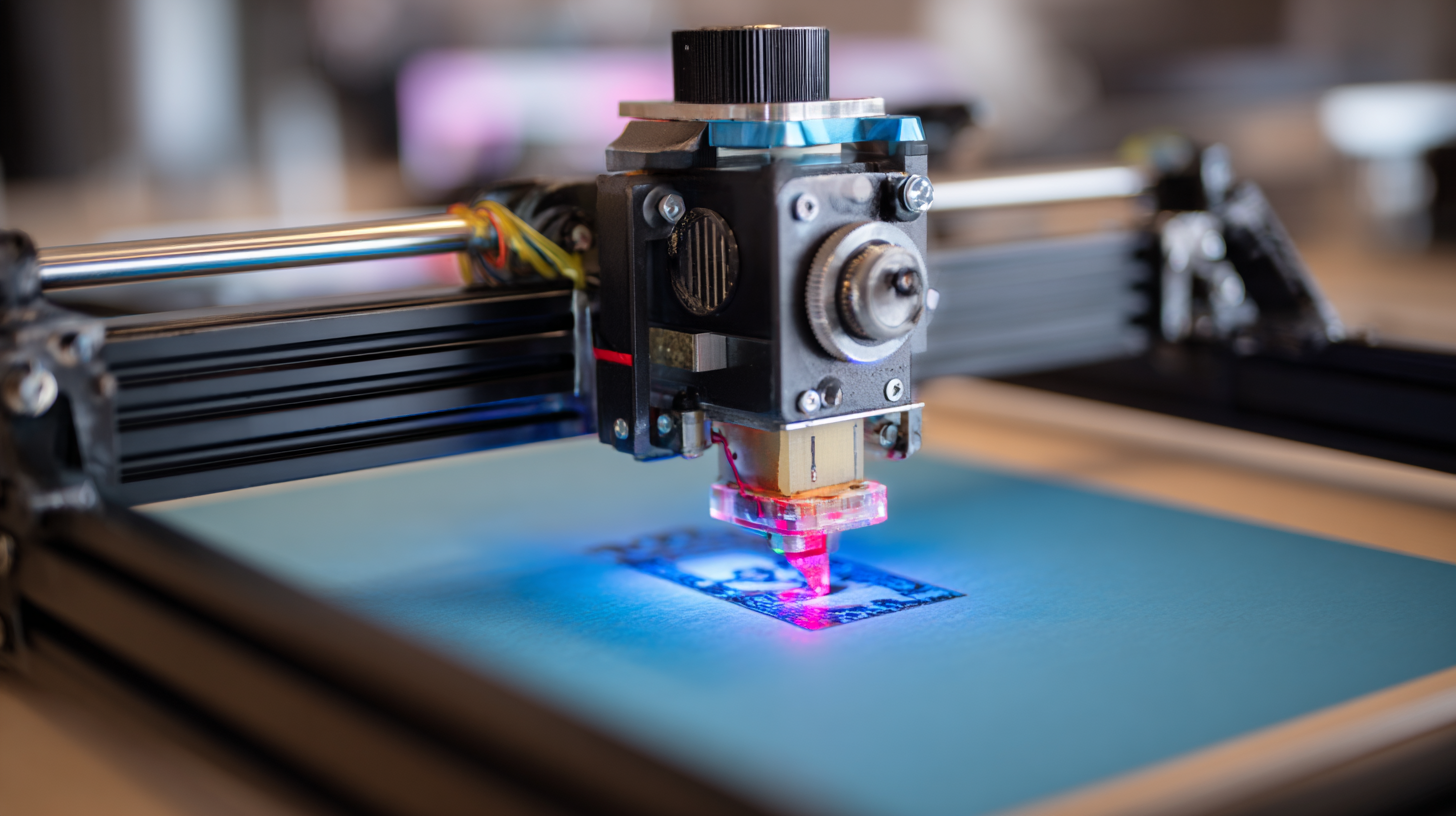

When considering the best laser engraving machine for your specific needs, it's essential to understand the various types of laser engraving technologies available. The most commonly used types include CO2 lasers, fiber lasers, and diode lasers, each with its unique strengths and applications. CO2 lasers are known for their versatility and effectiveness on non-metal materials like wood, acrylic, and leather, making them ideal for crafts and small businesses focused on personalized items.

On the other hand, fiber lasers offer higher precision and speed, particularly suitable for engraving metals, plastics, and glass. This technology is favored in industrial settings due to its efficiency and lower operational costs over time. Finally, diode lasers are often more compact and user-friendly, making them a popular choice for hobbyists and beginners. However, they typically have less power and are better suited for simpler projects. Understanding these distinctions will help you choose the right laser engraving machine according to the materials you work with and the complexity of your intended projects.

When selecting a laser engraving machine, one of the most effective strategies is to thoroughly research various brands and their customer reviews. Each brand often caters to different needs and applications, making it essential to understand their strengths and weaknesses. Look for brands that are well-known in the industry and have a reputation for reliability and quality. Pay attention to the specifications of the machines they offer, as this can significantly impact your engraving capabilities.

Customer reviews provide valuable insights that can help refine your choices. When reading reviews, consider both the positive and negative feedback from users who have a similar purpose in mind. Look for common themes in reviews, such as ease of use, consistency in engraving quality, and customer service experiences. Engaging with community forums and groups can also uncover real-life experiences, allowing you to make an informed decision that aligns with your specific needs and budget. By taking the time to research brands and reviews, you can identify the laser engraving machine that will best serve your projects.