1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

When it comes to finding the best laser engraving machine tailored to your specific needs, expert advice can be invaluable. According to Mark Thompson, a renowned laser engraving specialist with over a decade of experience in the industry, "Selecting the right laser engraving machine can significantly enhance your productivity and creativity, ultimately enabling you to achieve spectacular outcomes.” His insights highlight the importance of understanding one's requirements before making a purchase.

Choosing the best laser engraving machine involves considering factors such as project size, material compatibility, and budget constraints. With advancements in technology, the market now offers a variety of options, each with unique features and capabilities. Whether you're a hobbyist or running a small business, it's crucial to evaluate your priorities and how different machines can meet them.

As you embark on this journey, keep in mind that making an informed decision not only saves time and money but also ensures that you invest in a tool that aligns with your creative vision. By carefully assessing your options and seeking expert guidance, you can confidently select the best laser engraving machine that empowers you to bring your ideas to life.

When choosing a laser engraving machine, the first step is to clearly understand your unique engraving needs and requirements. Consider the types of materials you intend to work with, as this will significantly influence your choice. For instance, some machines are better suited for wood and acrylic, while others can handle metal or glass. Determining the thickness and size of the materials is crucial, as not all machines are equipped to engrave deeper or larger items.

Additionally, think about the scale and frequency of your projects. If you plan to engage in large-volume production or need to engrave intricate designs, a machine with higher precision and speed may be necessary. It's also important to assess your skill level and the machine's ease of use. For beginners, a user-friendly model with straightforward software might be suitable, while experienced users might prefer more advanced options that allow for greater customization. By carefully evaluating these factors, you can select a laser engraving machine that aligns with your specific needs and enhances your creative endeavors.

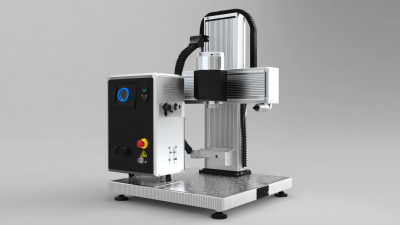

When selecting the best laser engraving machine for your needs, it's essential to understand the different types available on the market. Primarily, there are CO2 laser engravers, known for their versatility, as they can work on various materials such as wood, acrylic, glass, and leather. These machines are ideal for hobbyists and small business owners due to their affordability and ease of use.

Another type is fiber laser engravers, which excel in engraving metal surfaces and are often preferred in industrial applications. They provide high precision and faster processing times but come with a higher price tag.

Tips: When choosing a laser engraver, consider the size of materials you plan to work with. Ensure the machine has a sufficient bed size to accommodate your projects. Additionally, think about the wattage; higher wattage can cut and engrave quicker and deeper, enhancing productivity. Finally, look for a model that offers software compatibility that suits your design needs, as user-friendly software can greatly improve your engraving experience.

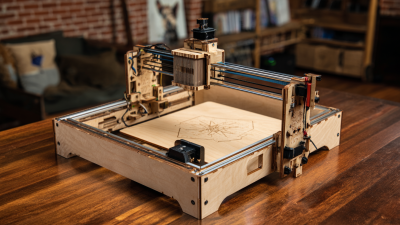

In addition to CO2 and fiber lasers, there are also diode laser engravers. These machines are generally more compact and affordable, making them perfect for beginners and those with limited workspace.

However, they may have limitations regarding material compatibility and engraving speed. Before investing in any machine, it's crucial to assess your specific requirements, such as the materials you intend to use and the complexity of your designs.

When selecting a laser engraving machine, it's essential to consider several key features that will impact your effectiveness and efficiency. First, the laser type is crucial. CO2 lasers are ideal for engraving wood, acrylic, and glass, while fiber lasers excel at working with metals. Understanding the materials you plan to work with will guide you in choosing the appropriate laser type, ensuring optimal results.

Another important feature is the machine's power and speed. Higher wattage allows for faster engraving and cutting, while speed settings offer versatility depending on the intricacy of the design. Consider the engraving area size as well, as larger machines accommodate bigger projects. Additionally, look for user-friendly software and compatibility with various design formats, ensuring a seamless workflow from concept to creation. These considerations will help you find a laser engraving machine that aligns perfectly with your specific needs and projects.

| Feature | Importance | Description | Typical Range |

|---|---|---|---|

| Laser Type | High | Determines the material compatibility and engraving quality. | CO2, Fiber, YAG |

| Working Area | Medium | Affects the size of projects that can be engraved. | 300x200 mm to 1000x600 mm |

| Power | High | Influences speed and depth of engraving. | 20W to 150W |

| Software Compatibility | Medium | Ensures the ability to design and manage projects efficiently. | CorelDRAW, AutoCAD, LightBurn |

| Cooling System | Medium | Prevents overheating and ensures consistent performance. | Air-cooled, Water-cooled |

| Maintenance Requirements | Low | Affects the cost and time needed for upkeep. | Low to High |

| Portability | Low | Determines how easily the machine can be moved. | Fixed, Desktop |

| Cost | High | Relates to the initial investment and potential ROI. | $200 to $10,000+ |

When selecting the best laser engraving machine, balancing cost and value is crucial. According to a recent industry report, the average entry-level laser engraver can range from $300 to $5,000, while higher-end models can cost upwards of $20,000. These prices often reflect features like cutting power, software capabilities, and the materials they can handle. For hobbyists or small business owners, understanding your budget while ensuring that you're not compromising on essential features is vital for maximizing your investment.

To effectively budget for a laser engraver, it’s helpful to first determine the types of projects you'll be working on. If you're focusing on intricate designs, investing in a machine that offers higher precision and versatility is worth the additional cost. Additionally, consider the long-term costs associated with materials and maintenance. According to a survey conducted by the Laser Institute, nearly 40% of users reported unforeseen expenses due to inadequate machine capabilities for their intended applications, which could have been avoided with proper foresight.

Tips for budgeting include setting a clear purpose for your machine beforehand. This allows you to avoid upselling on features you won't use. Additionally, consider the total cost of ownership; this includes not just the initial purchase price but also consumables, replacement parts, and potential upgrades. Conducting thorough research and comparing different models can help pinpoint the best value for your needs, ensuring that your investment pays off in both functionality and performance.

When selecting the best laser engraving machine for your projects, understanding material compatibility is crucial. Different materials react uniquely to laser engraving, which can significantly affect the quality and precision of your work. For instance, wood is a popular choice due to its ease of engraving and ability to produce beautiful results. However, the type of wood matters; softer woods may burn easily, while harder woods might require higher power settings for effective engraving. It’s essential to experiment with various settings to achieve the best finish.

Metals, on the other hand, present a different challenge. Laser engraving on metals typically necessitates higher-powered machines, and different metals yield varying results. Stainless steel, for instance, provides a clean finish when engraved, while anodized aluminum can be particularly effective in showcasing design details. Additionally, non-metal materials like acrylic or glass come with their own sets of requirements; acrylic can produce vibrant engravings but may melt if not handled properly. Understanding the specific needs and responses of each material will allow you to optimize your choice of laser engraving machine and enhance your overall project outcomes.