1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

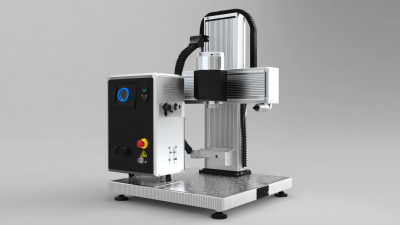

When it comes to precision and efficiency in marking and engraving, a fiber laser marking machine stands out as an essential tool for various industries. Choosing the right machine for your business needs can significantly impact your production capabilities and product quality. This decision is not merely about selecting a laser marker but involves a comprehensive understanding of the technology, its applications, and how well it aligns with your specific requirements.

In the realm of manufacturing, logistics, and product customization, the demand for high-quality marking solutions continues to rise. A fiber laser marking machine offers versatility across a broad spectrum of materials, ensuring clear, durable, and precise markings suitable for a wide range of applications, from industrial parts to promotional items. However, navigating the myriad options available can be daunting. Businesses must consider factors such as power output, speed, operational costs, and maintenance requirements to determine which machine best meets their operational goals.

This guide aims to provide insights into the key considerations that should influence your choice of a fiber laser marking machine. By understanding these critical aspects, you will be better equipped to make an informed decision that enhances your operational efficiency and helps your business thrive in a competitive landscape.

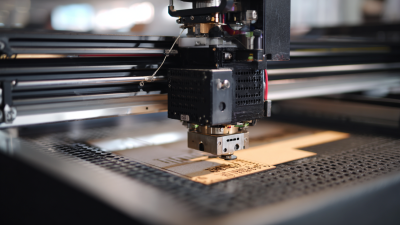

Fiber laser marking technology has transformed the way businesses approach product identification and branding. This advanced technology utilizes a high-intensity fiber laser beam to create permanent marks on various materials, including metals, plastics, and ceramics. The precision of fiber lasers enables detailed designs, barcodes, and serial numbers to be etched with remarkable clarity. This capability is essential for industries that require strict traceability and branding, such as automotive, pharmaceuticals, and electronics.

The applications of fiber laser marking are diverse. For instance, manufacturers can use it for engraving logos and product information, enhancing their brand recognition while ensuring compliance with industry standards. Additionally, fiber lasers are integral to the customization of products, enabling businesses to offer personalized items to their customers efficiently. With the ability to mark materials at high speeds and with minimal thermal distortion, fiber laser marking ensures that both quality and efficiency are maintained, making it a valuable asset for any business looking to improve its marking processes.

| Feature | Description | Importance Level |

|---|---|---|

| Wavelength | Typically around 1064 nm, suitable for a range of materials. | High |

| Marking Speed | Fast speed, usually in the range of 7000 mm/s. | High |

| Power | Options from 20W to 100W based on application needs. | Medium |

| Cooling System | Air-cooled vs. water-cooled; water-cooled offers better performance. | Medium |

| Software Compatibility | Support for various design software formats (e.g., .ai, .dxf). | High |

| Material Types | Effective on metals, plastics, wood, and more. | High |

| Operating Environment | Indoor vs. outdoor use can affect cooling and protection needs. | Medium |

| Warranty & Support | Duration of warranty and availability of customer support. | High |

When selecting a fiber laser marking machine for your business, several key factors should be taken into account to ensure it fits your operational needs. First, consider the material you will be working with. Fiber lasers are particularly effective for marking on metals and some plastics, so understanding the primary materials your products are made from can help you choose a machine with the appropriate wattage and capabilities for optimal performance.

Additionally, assess the size and complexity of the items you'll be marking. A machine with a larger engraving area may be necessary for bigger components, while those requiring intricate designs might benefit from a model that offers higher precision and speed. Furthermore, the level of automation and user-friendliness of the machine is crucial; features such as intuitive software and easy setup can significantly enhance productivity and minimize training time for your operators. By evaluating these factors, you can ensure that the fiber laser marking machine you select aligns with your specific business requirements and enhances your production efficiency.

When evaluating the specifications and features of fiber laser marking machines for your business, it's essential to consider several key factors that will impact both your operational efficiency and the quality of your output. Firstly, assess the laser power and wavelength, as these determine the machine’s capability to mark on different materials. Higher power lasers can mark more efficiently on harder substrates, while specific wavelengths are better suited for particular materials.

Additionally, consider the marking area size and speed. A larger marking area can enhance productivity, especially if your business involves larger items or batches. The speed of the machine is also critical; a faster marking process can significantly reduce production time, making your operations more efficient.

Tips: When choosing a machine, prioritize a model with adjustable settings for both speed and power. This flexibility allows you to effectively handle a wider range of materials and applications. Also, examine the cooling system; effective cooling not only extends the machine's lifespan but also ensures consistent marking quality over time. Lastly, inquire about the software integration capabilities, as a user-friendly interface can streamline your workflow significantly.

When selecting the best fiber laser marking machine for your business needs, it's essential to compare different brands and models based on key performance indicators. According to a 2022 industry report, the global market for fiber laser marking machines is projected to reach $1.03 billion by 2026, growing at a compound annual growth rate (CAGR) of 7.4%. This significant growth highlights the importance of choosing a machine that not only meets your immediate requirements but also aligns with future technological advancements.

Different models come with varied specifications, such as laser power, marking speed, and software integration capabilities. A study by the Laser Institute of America indicated that machines with a laser power range of 20W to 100W are optimal for most industrial applications, providing a balance between efficiency and cost-effectiveness. Additionally, the latest advancements in fiber laser technology have improved the quality of engravings while reducing downtime, making it crucial to consider models that offer enhanced operational stability and minimal maintenance costs.

Furthermore, the choice of a fiber laser marking machine should also factor in the type of materials you plan to work with. For instance, metals, plastics, and ceramics have different engraving requirements, and some machines are better suited for specific materials. A comprehensive comparison of available options can help businesses identify the right equipment that not only meets industry standards but also maximizes productivity and minimizes operational costs in the long run.

When considering the purchase of a fiber laser marking machine, effective budgeting and cost analysis are critical to ensuring long-term value for your business. According to a report from MarketsandMarkets, the global fiber laser market is projected to grow from $2.5 billion in 2020 to $5.2 billion by 2025, highlighting the increasing demand and potential return on investment for businesses in various sectors. This growth underscores the importance of careful financial planning when investing in laser marking solutions.

To develop a sound budget, assess the initial purchase price against the operational costs associated with maintenance and consumables. A cost analysis should include factors such as energy consumption, potential downtime, and the longevity of the machine. Expert insights suggest that over a typical operational lifespan, a fiber laser marking machine may reduce marking costs by up to 70% compared to traditional methods. This shift not only enhances your production efficiency but also impacts your overall profitability.

Tips:

1. Utilize a calculator for total cost of ownership (TCO) to compare different models and factoring maintenance and operational costs.

2. Consider potential financing options that may be available, enabling you to allocate your budget more strategically and spread out the cost over time.

3. Research potential savings in materials and labor that fiber lasers can facilitate, as these can significantly offset initial investment costs.