1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

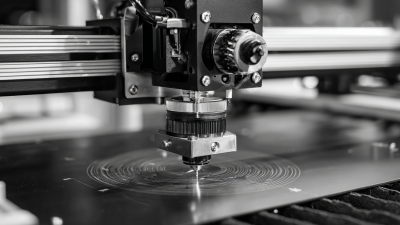

In today’s crafting and manufacturing landscape, precision and efficiency are paramount. One tool that embodies these qualities is the laser etching machine. Unlike traditional engraving methods, laser etching machines utilize advanced technology to deliver intricate designs with unparalleled accuracy. This innovation has revolutionized the way artists, makers, and businesses approach their projects, allowing for a broad range of applications from personalized gifts to industrial part marking.

The versatility of a laser etching machine makes it an invaluable asset for anyone looking to enhance their creative output. With the ability to engrave on various materials such as wood, glass, metal, and plastic, these machines open up new possibilities for customization and uniqueness. Additionally, the speed at which a laser etching machine operates allows creators to streamline workflows while maintaining high-quality results. This capability not only increases productivity but also allows for the efficient execution of complex designs that would be challenging with manual methods.

Choosing a laser etching machine is not just about acquiring a tool; it’s about investing in a future where creativity meets cutting-edge technology. Whether you're a hobbyist, an entrepreneur, or someone looking to explore the world of engraving, understanding the benefits of this technology will equip you to make informed decisions for your projects. Embrace the potential of laser etching machines and unlock a new realm of possibilities for your artistic and industrial endeavors.

Laser etching machines have revolutionized precision work in various industries, notably in manufacturing and art applications. According to a report by Smithers Pira, the global market for laser processing technology is projected to reach USD 5.6 billion by 2025, highlighting the growing preference for these cutting-edge tools. One of the key advantages of laser etching is its high level of accuracy. Laser machines can etch designs with a resolution as fine as 0.001 inches, making them ideal for intricate projects such as jewelry design and electronic component labeling, where precision is paramount.

Moreover, the versatility of laser etching machines is another significant factor contributing to their increasing adoption. These machines are capable of working on a variety of materials, including metal, wood, glass, and plastic, without the need for extensive tooling changes. A study published in the Journal of Manufacturing Science and Engineering notes that laser etching provides not only detailed engraving but also the ability to customize products in short runs, catering to the rising demand for personalization in manufacturing. This adaptability ensures that businesses can meet unique customer specifications efficiently, ultimately improving productivity and reducing waste in the production process.

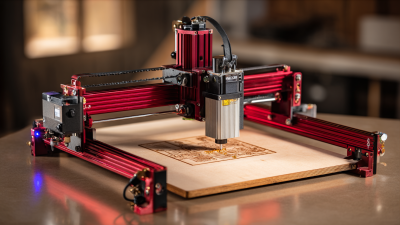

Laser etching technology has revolutionized the way various materials can be utilized for projects across diverse industries. One of the remarkable aspects of this technology is its compatibility with a wide range of materials. Commonly used materials for laser etching include acrylic, wood, glass, leather, and metal. According to a report by Market Research Future, the global laser engraving market is expected to reach USD 4.18 billion by 2023, with a significant increase in the adoption of laser technology for both industrial and personal projects. This versatility allows creators and businesses to personalize items, create intricate designs, and streamline production processes.

Acrylic, for instance, is particularly popular for laser etching due to its clarity and ability to be cut into intricate shapes and designs. The laser precisely removes the surface layer to create detailed images or text, making it ideal for awards, signage, and decorative items. Wood, another favored material, benefits from the organic finish given by laser etching, which can enhance the aesthetics of personalized gifts, furniture, and crafts. Furthermore, metals like stainless steel and aluminum are increasingly being etched with lasers, allowing for durable markings that can withstand harsh environments, vital for industrial equipment and tools. The ability to work with these varied materials not only enhances creativity but also meets the specific needs of various applications, ensuring that laser etching machines continue to play a crucial role in modern manufacturing and craftwork.

When comparing laser etching to traditional methods, it becomes clear that laser technology offers several advantages that can significantly enhance project outcomes. Traditional etching, often reliant on mechanical processes, can be limited in terms of precision and the complexity of designs. This may result in uneven finishes or the inability to reproduce intricate details consistently. In contrast, laser etching provides unparalleled accuracy, allowing for complex patterns and fine detail that can be replicated effortlessly across multiple pieces.

Moreover, the efficiency of laser etching surpasses that of traditional methods. The setup time and processing speed of laser machines are typically superior, meaning projects can be completed faster without compromising on quality. Traditional methods might require numerous steps, such as carving, sanding, or applying stencils, which can be time-consuming and labor-intensive. Laser etching streamlines this process by automating many of these tasks, leading to increased productivity and the ability to quickly adapt designs as needed, which is particularly beneficial in high-demand situations or for custom orders.

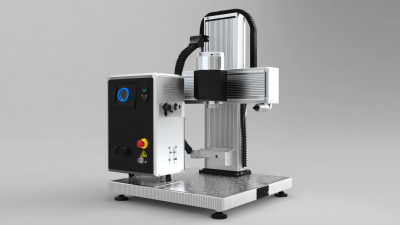

Laser etching technology has revolutionized various industries by providing precise and durable marking solutions. One of the primary applications is in the manufacturing sector, where laser etching is employed for branding, serial number engraving, and part identification. This process not only ensures detailed markings on components but also enhances the traceability of products, which is crucial for quality control and compliance with industry regulations.

Another significant application of laser etching can be found in the personalized products market. Items such as jewelry, gifts, and promotional materials often feature custom engravings that enhance their appeal. The versatility of laser etching allows for intricate designs and text, meeting the diverse needs of consumers while maintaining high-quality finishes. Additionally, the use of laser technology minimizes waste compared to traditional methods, making it an environmentally friendly choice for companies focused on sustainability.

In the realm of medical devices, laser etching plays a vital role in labeling surgical instruments and implantable devices. The high precision of laser marking ensures that vital information is permanently etched onto surfaces, reducing the risk of miscommunication in critical healthcare settings. This application showcases the reliability and importance of laser etching across various fields, underscoring its value in enhancing product safety and efficacy.

Laser etching machines offer significant cost-effectiveness and efficiency for various projects, making them an excellent choice for businesses and hobbyists alike. A recent industry report highlighted that laser etching can reduce production costs by up to 30% compared to traditional engraving methods, primarily due to the reduced material waste and decreased labor time involved. Furthermore, laser etching machines enable faster processing speeds, often completing tasks in half the time of conventional techniques, which translates to increased output and profitability.

One key advantage of laser etching is its versatility. These machines can etch a wide range of materials, including wood, metal, glass, and plastic. This adaptability allows users to take on diverse projects without needing multiple machines, which further lowers upfront costs and maintenance expenses. Additionally, laser etching provides high precision and detail, which reduces the need for post-processing, further enhancing operational efficiency.

Tips: When considering a laser etching machine, assess your project needs carefully and choose a model that provides flexibility in material handling. Also, invest in training to maximize efficiency and minimize errors during the etching process. Engaging in regular maintenance checks can ensure consistent performance and longevity of your machine, ultimately enhancing your return on investment.