1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

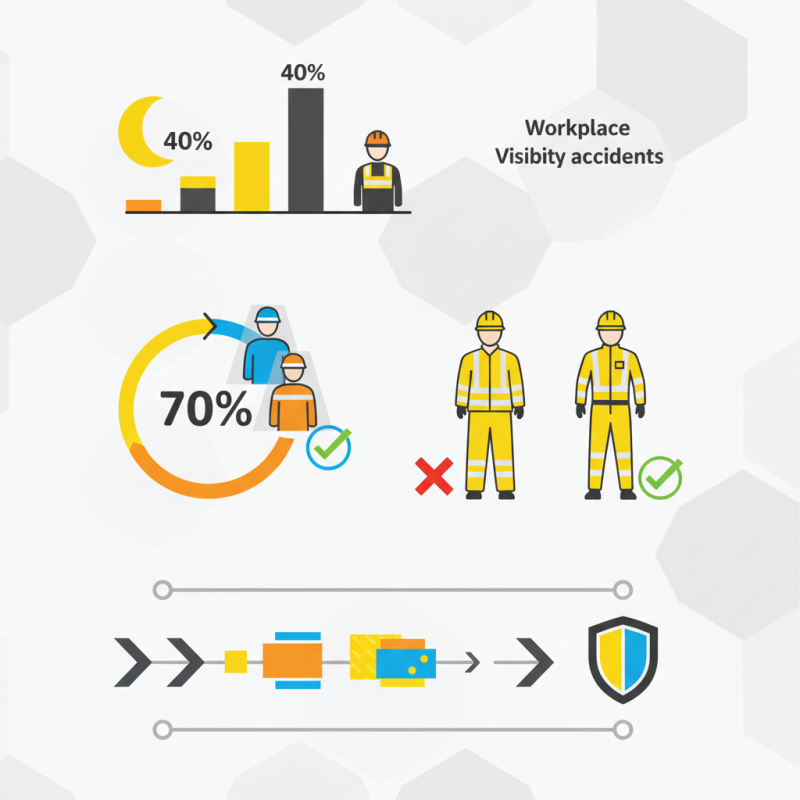

In 2026, safety and visibility in the workplace remain paramount concerns. reflective workwear plays a crucial role in enhancing worker safety. According to a recent industry report, nearly 40% of workplace accidents occur in low-light conditions. This statistic highlights the need for well-designed reflective garments.

reflective workwear not only promotes visibility but also contributes to a culture of safety. Studies show that workers wearing reflective materials are 70% less likely to be involved in accidents. However, while many companies are adopting these standards, some still overlook the importance of proper fit and wear. Ill-fitting reflective gear can reduce effectiveness, leading to potential hazards.

As manufacturing continues to evolve, new materials and designs emerge. Employers must continually reassess their workwear choices to meet safety guidelines. A failure to adapt can leave workers vulnerable. Thus, selecting the best reflective workwear is not merely a trend; it is a necessity for workplace safety in the years ahead.

When choosing reflective workwear for 2026, focus on essential features that enhance safety and visibility. The fabric should have high-quality reflective strips. These strips need to be strategically placed for maximum effect. Look for designs that allow for 360-degree visibility. Comfort is crucial, too; breathable materials help during long hours on the job.

Additionally, consider the fit of the workwear. Loose-fitting clothing may hinder movement, while overly tight options can be uncomfortable. Adjustable features can make a big difference. Visibility also depends on the color of the fabric. Bright colors like neon yellow or orange stand out in diverse environments.

Finally, durability is a key factor. The wear and tear of daily use can affect the effectiveness of reflective elements. Regular inspections of workwear can help maintain safety standards. Reflecting on these aspects can lead to better choices in protective gear. The right workwear can significantly improve workplace safety.

Reflective workwear is essential for safety in low-light conditions. Different types of reflective materials are designed to enhance visibility. The most common types include glass beads, microprismatic, and fluorescent materials. A recent industry report states that reflective materials can improve visibility by up to 1,200 feet, reducing accidents in hazardous environments.

Glass beads are often used in high-visibility garments. They are effective in reflecting light back to its source. Microprismatic materials offer superior brightness and clarity. They work well in various weather conditions. Fluorescent materials enhance visibility during the day. They absorb light and appear brighter in daylight. Each of these materials serves a purpose in enhancing worker safety.

Tips: Choose garments based on your work environment. Consider the level of visibility needed. Reflective workwear is not a luxury; it’s a necessity. Regularly inspect your gear for wear and tear. Ensure that reflective surfaces remain unobstructed. This will maintain their effectiveness.

The right choice matters. Not all reflective materials perform equally in every situation. Future designs might focus on comfort and flexibility. Integrating technology could lead to innovative solutions. Reflective workwear must adapt to changing needs in the workplace. This ongoing evolution demands attention to detail in material selection and application.

When it comes to reflective workwear, different industries have unique needs. Construction workers often face hazards from vehicles and equipment. In a 2022 report by the Occupational Safety and Health Administration (OSHA), around 20% of construction-related fatalities involved vehicles. High-visibility clothing can mitigate these risks significantly. Workers should consider options with bright colors and large reflective strips.

In the transportation industry, visibility is crucial during low-light hours. A study from the National Highway Traffic Safety Administration (NHTSA) indicated that nearly 60% of fatal accidents occur at night. Ensuring that workers wear reflective gear helps others see them from a distance. Using retroreflective materials can enhance safety, especially in road maintenance tasks.

However, not all reflective workwear is created equal. Comfort and breathability are often overlooked. Workers may feel restricted or overheated if the clothing isn't designed properly. Reports have shown that 30% of workers do not adhere to safety gear guidelines, primarily due to discomfort. Employers should prioritize gear that merges safety with comfort to enhance compliance.

Reflective workwear has evolved significantly. In 2026, innovations in reflective technology are at the forefront of safety. New materials enhance visibility, even in low-light conditions. These fabrics reflect more light, creating a striking contrast against dark backgrounds. Wearers can feel more confident on the job, knowing they are seen.

However, not all reflective gear is created equal. Some options may not offer adequate breathability or comfort. This can impact wearers negatively during long hours. It's vital to find the right balance between visibility and comfort. Heavy materials may limit movement, affecting productivity.

New features are emerging, like adaptive visibility technology. This includes reflective patches that dynamically change based on light exposure. Such advancements can greatly improve safety for workers. Still, thoughtful consideration is needed when selecting the right gear. Each worker has unique requirements based on their job conditions. Finding the best fit is essential for optimal performance and safety.

| Workwear Type | Reflective Material | Visibility Rating | Weather Resistance | Weight (g/m²) |

|---|---|---|---|---|

| High-Visibility Jacket | Retroreflective Tape | Class 3 | Waterproof | 220 |

| Reflective Overalls | Flame-Resistant Fabric | Class 2 | Oil Resistant | 300 |

| Reflective Safety Vest | Luminous Fabric | Class 1 | Lightweight | 150 |

| Reflective Work Pants | Microprismatic Reflective Tape | Class 3 | Water-Resistant | 260 |

Reflective workwear plays a crucial role in various sectors. In construction, for example, workers often face hazardous conditions. Regulatory standards dictate that these garments must feature high-visibility colors and reflective materials. This ensures they remain visible, especially in low-light situations. Different regions may have specific requirements, so understanding local regulations is essential.

In road maintenance, reflective wear protects workers from traffic hazards. Regulations usually mandate certain levels of reflectivity and specific designs. Workers must wear gear during day and night. This constant visibility can make a significant difference. Yet, compliance isn't always perfect. Some workers might overlook the importance of proper fit. If clothes are too loose or too tight, they could fail to provide adequate protection.

In emergency services, reflective gear is vital during rescue operations. Standards often require markings that are easily discernible in chaos. However, not all reflective wear meets these demands. A thorough evaluation of gear can expose gaps in safety. Industry professionals sometimes need reminders about the importance of quality and fit. Prioritizing safety and visibility could save lives in critical situations.