1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

In today's competitive manufacturing landscape, businesses are constantly seeking innovative solutions to increase efficiency and improve product quality. One such solution that has gained significant traction is the laser welding machine. According to Dr. Emily Chen, a leading expert in advanced welding technologies, "The laser welding machine not only enhances precision and control but also significantly reduces production times.” This revolutionary technology has reshaped the way industries approach welding, offering a plethora of benefits that can drive success.

The advantages of incorporating a laser welding machine into a manufacturing process are numerous and impactful. From extraordinary speed and accuracy to reduced material waste and enhanced safety, these machines represent the future of welding technology. As businesses look for ways to streamline operations and remain competitive, understanding the top benefits of laser welding becomes essential. In this article, we will explore the top 10 advantages that laser welding machines bring to the table, illuminating how they can transform your business and lead to greater profitability.

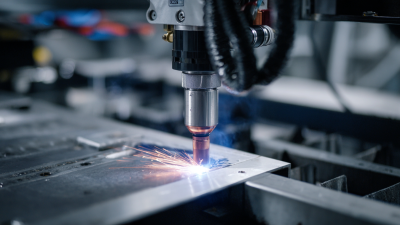

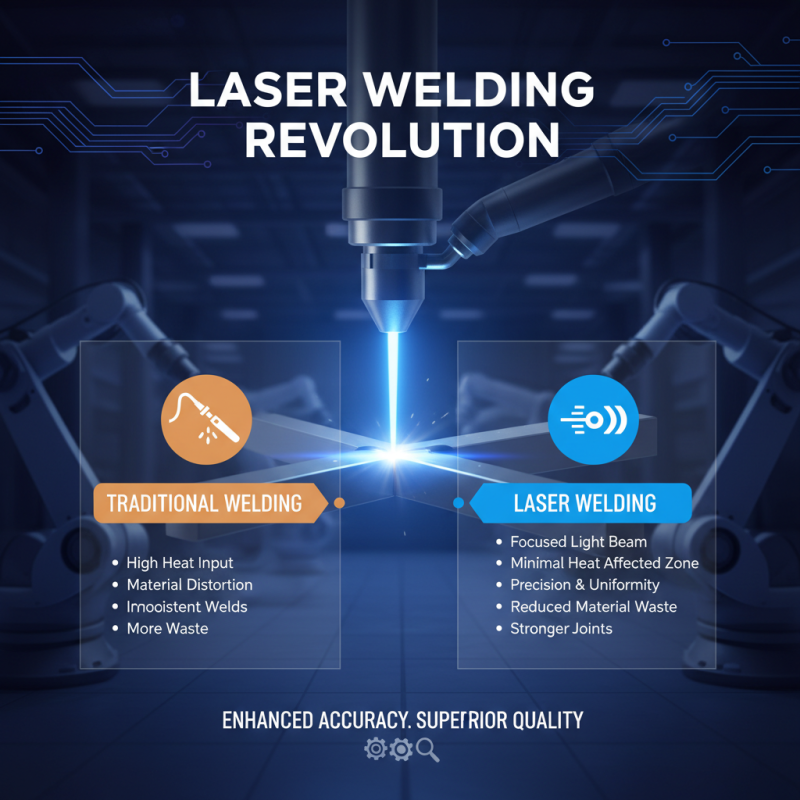

Laser welding technology has revolutionized the manufacturing landscape, particularly through its ability to enhance precision and accuracy in welding processes. Unlike traditional methods, laser welding utilizes a focused beam of light to join materials, resulting in minimal heat input and reducing the risk of distortion or damage to surrounding areas. This precision ensures that welds are consistently strong and uniform, leading to higher quality products and reduced material wastage.

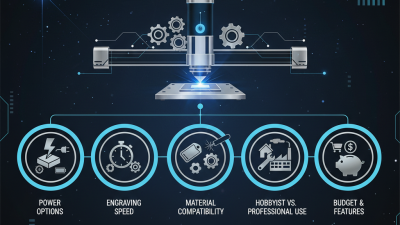

One significant benefit of increased accuracy in laser welding is the ability to work with complex designs and thinner materials. The laser’s narrow focus allows for intricate welds that were previously challenging or impossible to achieve. This not only expands the design possibilities but also opens up new market opportunities for businesses that are looking to innovate. As a tip, consider integrating laser welding into your production line if you frequently work with materials that require high precision, such as in the aerospace or medical device industries.

Moreover, the consistency inherent in laser welding processes minimizes the need for extensive post-weld inspections and rework. This streamlining of production cycles can lead to substantial cost savings and enhance overall productivity. To maximize these benefits, it’s advisable to invest in proper training for machine operators and maintain regular equipment servicing. By prioritizing operator skill and machine upkeep, businesses can ensure that they achieve the full potential of laser welding technology.

Laser welding technology has emerged as a leading solution in modern manufacturing, thanks to its ability to minimize material waste effectively. Unlike traditional welding methods, which often result in significant scrap materials due to excessive heat and imprecise joining, laser welding focuses energy on a small area, ensuring a cleaner and more efficient weld. This precision not only leads to higher quality products but also dramatically reduces the amount of excess material that needs to be discarded.

Moreover, the cost efficiency associated with reduced material waste translates directly into financial savings for businesses. By utilizing laser welding, companies can better optimize their material consumption, allowing them to allocate resources more strategically. This means that fewer raw materials are required for production, which not only cuts costs but also contributes to a more sustainable manufacturing process. As businesses strive to enhance their profitability while maintaining environmental responsibilities, adopting laser welding techniques is proving to be a smart investment.

The integration of laser technology into manufacturing processes has significantly transformed production dynamics, primarily through enhanced speed. Laser welding machines utilize concentrated beams of light to make precise and efficient welds, drastically reducing the time needed for traditional welding methods. This acceleration in production rates not only increases output but also allows businesses to respond more rapidly to market demands, creating a competitive edge.

Moreover, the ability to perform rapid and accurate welds with minimal heat affected zones means that subsequent processes can begin sooner, further streamlining the overall production timeline. The precision of laser welding eliminates the need for extensive post-processing, which is often required with other welding methods. As a result, companies can allocate resources more effectively, maximize production efficiency, and minimize downtime, transforming their operational capabilities and ultimately driving profitability.

Laser welding technology has carved a significant niche across various industries, revolutionizing traditional welding methods. One of the major sectors benefiting from this advanced solution is the automotive industry. According to a report by Market Research Future, the global automotive welding market is expected to grow substantially, with laser welding solutions accounting for a major segment due to their precision and speed. Manufacturers leverage laser welding to create strong, lightweight joints, which are crucial for enhancing vehicle efficiency and performance.

In addition to automotive applications, the aerospace sector has also seen remarkable improvements thanks to laser welding. The American Institute of Aeronautics and Astronautics reports that the lightweight structures and intricate designs required in modern aircraft can be achieved more effectively with laser welding. This technology not only enables the combination of different materials, such as titanium and aluminum, but also guarantees minimal thermal distortion, maintaining the integrity of critical components. As industries continue to seek higher efficiency and reduced costs, the versatile applications of laser welding solutions are becoming indispensable.

The integration of laser welding technology into industrial operations significantly enhances workplace safety. Traditional welding methods often involve high temperatures and open flames, posing substantial risks of burns and fires. In contrast, laser welding utilizes a concentrated beam of light to effectively join materials, minimizing the exposure to hazardous conditions. According to a report by the American Welding Society, injuries related to traditional welding techniques account for over 30% of all welding-related accidents, underscoring the pressing need for safer alternatives.

Moreover, advanced laser welding machines come equipped with sophisticated safety features such as automatic shut-off systems and protective enclosures that further mitigate risk. These systems are designed to activate in the event of a malfunction, significantly reducing the chance of accidents. A study published in the International Journal of Advanced Manufacturing Technology found that workplaces using laser welding reported a 40% decrease in incident rates compared to those reliant on conventional methods. This not only fosters a safer environment but also contributes to increased employee morale and productivity, as workers feel more secure in their operating conditions.