1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

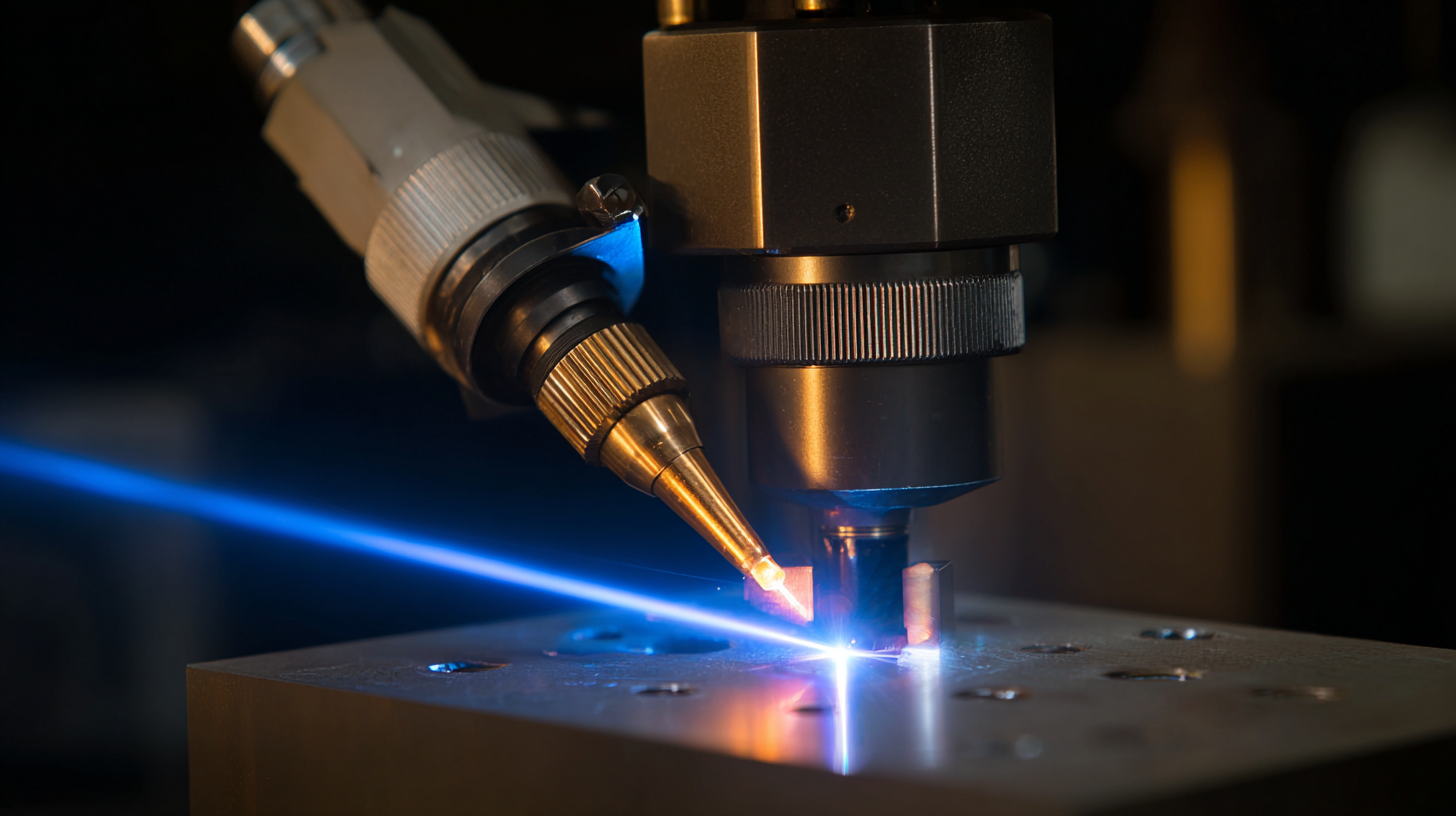

In the high-precision landscape of modern manufacturing, the adoption of advanced technologies is crucial for maintaining competitive advantages. One such technology, the laser welding gun, has emerged as a game-changer, offering remarkable efficiency and accuracy.

According to a report by MarketsandMarkets, the laser welding market is projected to reach $5.49 billion by 2026, growing at a CAGR of 5.6%. This surge highlights the increasing reliance on laser welding guns for applications that require impeccable joint quality and reduced thermal distortion.

The precision and versatility of laser welding guns not only streamline the production processes but also enhance product durability, which is essential in industries ranging from automotive to aerospace.

As manufacturers seek to optimize their operations, understanding the ten incredible benefits of laser welding guns becomes paramount for driving innovation and achieving operational excellence.

The precision and versatility of laser welding guns not only streamline the production processes but also enhance product durability, which is essential in industries ranging from automotive to aerospace.

As manufacturers seek to optimize their operations, understanding the ten incredible benefits of laser welding guns becomes paramount for driving innovation and achieving operational excellence.

Advancements in laser welding technology have significantly impacted precision manufacturing, enabling a higher level of accuracy and effectiveness in various applications. The global laser optics market is projected to reach an estimated $19.23 billion by 2030, reflecting the growing demand for precise manufacturing equipment. This increase is driven by the necessity for improved efficiency and reduced material wastage, particularly in sectors like automotive and electronics, where precision is paramount.

Advancements in laser welding technology have significantly impacted precision manufacturing, enabling a higher level of accuracy and effectiveness in various applications. The global laser optics market is projected to reach an estimated $19.23 billion by 2030, reflecting the growing demand for precise manufacturing equipment. This increase is driven by the necessity for improved efficiency and reduced material wastage, particularly in sectors like automotive and electronics, where precision is paramount.

One of the key factors improving precision in laser welding is the development of advanced manufacturing methods tailored for specific materials. As industries evolve, the right selection of welding methods becomes critical. For instance, electric vehicle production leverages laser welding extensively to meet the stringent requirements of lightweight materials and high-strength joints, showcasing the technology's adaptability.

Tips for Enhancing Precision in Laser Welding:

Laser welding guns have revolutionized precision manufacturing by harnessing focused beams of light to achieve exceptional welding accuracy and quality. The core mechanism involves generating a concentrated laser beam that melts the material at a specific point, allowing for precise control over the weld depth and width. This high-intensity heat source can be finely adjusted, enabling manufacturers to work with a variety of metals and thicknesses without the risk of warping or damaging the material.

Furthermore, the integration of advanced computer systems with laser welding technology enhances its precision. These systems allow for real-time adjustments during the welding process, ensuring optimal melting conditions and consistent results. The ability to automate the welding process with programmed parameters leads to increased efficiency and reproducibility in manufacturing. This precision not only results in stronger welds but also minimizes the need for post-welding machining, reducing overall production time and costs.

The financial benefits of implementing laser welding technology in precision manufacturing are becoming increasingly clear, particularly in an era where cost optimization is crucial. A comprehensive analysis published recently highlights that laser welding guns can significantly reduce production time due to their speed and efficiency, which, in turn, directly translates to lower labor costs. Additionally, the precision offered by laser welding minimizes material waste, a vital factor given that the manufacturing sector contributes heavily to energy consumption and greenhouse gas emissions. Integrating laser welding can lead to a reduction of operational costs by up to 30%, a substantial incentive for manufacturers aiming to enhance their bottom lines.

Moreover, with the rise of automation in manufacturing, laser welding guns are proving to be more than just a cost-saving measure; they also facilitate scalability. A recent report indicates that companies utilizing advanced laser welding technologies can see improvements in their production rates by over 40%. This efficiency is vital as industries pivot towards sustainable practices amidst growing concerns regarding environmental impact. In this context, laser welding not only fosters financial advantages but also supports a shift towards greener manufacturing solutions, aligning with global trends in sustainable production methods.

Laser welding technology has rapidly evolved, becoming a crucial tool across various manufacturing sectors. Its precision and efficiency have found applications in industries such as automotive, aerospace, and electronics. In the automotive sector, laser welding is used for creating strong, lightweight components that enhance vehicle performance and safety. In aerospace, the ability to weld complex shapes with minimal heat input ensures the integrity of critical components, while the electronics industry benefits from the precise joining of delicate parts without damaging sensitive materials.

**Tips**: When considering laser welding for your manufacturing operations, it's essential to assess the specific requirements of your project. Make sure to collaborate with a vendor who understands your industry's unique challenges and can provide tailored solutions. Additionally, investing in operator training can significantly improve the outcomes of your welding processes, ensuring both efficiency and quality.

Versatility is a hallmark of laser welding; it can be implemented in varied material types such as metals, plastics, and even ceramics. This flexibility allows manufacturers to innovate and adapt their product designs, meeting the growing demands of consumers for diverse and sophisticated products. Exploring the potential of laser welding in different contexts offers companies a competitive edge in an ever-evolving marketplace.

Quality control in precision engineering is paramount, particularly when it comes to evaluating the effectiveness of laser welding techniques. These methods have revolutionized the manufacturing landscape by offering enhanced precision and reduced thermal distortion. To measure the success of laser welding, several quality control metrics come into play, such as weld strength, consistency, and surface finish. These metrics provide engineers with quantifiable data that can directly influence production processes and end product quality.

The ability to conduct real-time monitoring during the laser welding process further enhances quality control efforts. Parameters like laser power, feed rate, and spot size are crucial indicators that can be adjusted to optimize the welding outcome. By implementing stringent quality metrics, manufacturers can ensure that each weld meets the required specifications, thereby minimizing the risk of defects and increasing overall production efficiency. In an industry where precision is non-negotiable, effective quality control in laser welding not only boosts product reliability but also drives competitive advantage.