1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

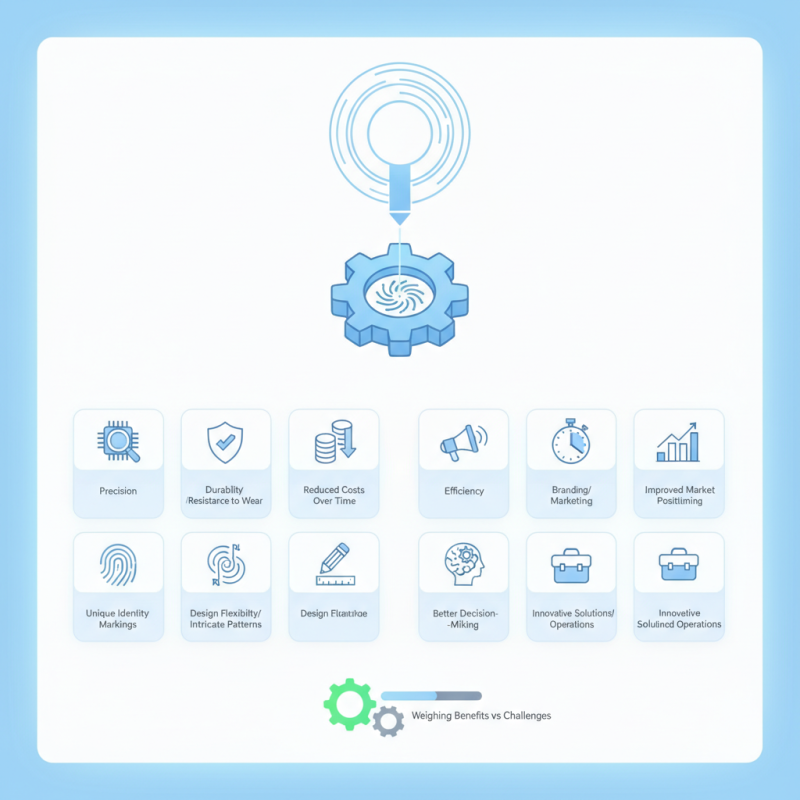

In today's competitive landscape, businesses constantly seek innovative solutions to enhance their operations. One such solution is laser marking, a method that has gained traction across various industries. Dr. Emily Carter, a leading expert in laser technologies, once noted, "Laser marking can transform the way products are identified and marketed." This technology offers numerous benefits that can significantly impact a company's efficiency and branding.

Laser marking provides precision and durability in product labeling. Unlike traditional methods, it ensures marks are permanent and resistant to wear. This can lead to reduced costs over time, as companies spend less on re-labeling. Moreover, the design flexibility of laser marking allows for intricate patterns that can enhance product aesthetics. Many businesses have achieved a unique identity through customized markings.

However, the adoption of laser marking is not without its challenges. Initial investment costs can be high, and some users may find the technology daunting. It's crucial to weigh the benefits against these factors. Still, for many companies, the advantages outweigh the drawbacks. Exploring the top benefits of laser marking can guide businesses toward better decision-making and improved market positioning.

Laser marking technology offers remarkable precision that can significantly enhance business operations. The process uses focused laser beams to create designs, texts, or codes on various materials. This method allows for intricate details that traditional marking methods cannot achieve. For example, logos can be rendered with fine lines and clean edges, making the final product visually appealing. Additionally, with adjustable settings, businesses can tailor the depth and contrast of markings to suit specific needs.

Enhanced detail is not just about aesthetics; it also improves functionality. In many industries, clear marking is essential for compliance and traceability. For instance, medical devices must have precise labels to ensure safety and regulation adherence. However, achieving such accuracy can be challenging. Sometimes, a small miscalculation might lead to error, affecting the entire production line. Frequent checks and adjustments are necessary to maintain quality, indicating that even advanced technology demands oversight. Embracing laser marking means inviting creativity and precision, but it requires ongoing commitment to perfect the process.

Laser marking technology is transforming how businesses operate. One major benefit is the significant reduction in production costs. With laser marking, there are fewer materials wasted during the marking process. Traditional methods often require extra materials, which can inflate expenses unnecessarily. By using lasers, businesses can achieve precise markings with minimal waste.

Moreover, laser marking requires less maintenance than conventional marking systems. Many older methods need frequent adjustments and repairs. This can lead to unplanned downtime and increased costs. With laser systems, reliability is improved. Over time, companies can save on both labor and repairs, enhancing overall efficiency.

However, it's important to recognize the initial investment in this technology. Some businesses may find it challenging to allocate funds for new equipment. This leads to hesitation and potential missed opportunities. Finding the right balance between cost and innovation remains a critical concern for many. Embracing laser marking could be the key to unlocking streamlined production and lower costs.

Laser marking significantly enhances product durability. The advanced technology creates permanent markings without compromising material integrity. This is crucial for industries like aerospace and medical devices, where failure is not an option. According to a report by Research and Markets, laser marking can improve traceability and help maintain high quality standards.

The versatility of laser marking allows it to be applied across multiple materials, from metals to plastics. This impacts quality assurance processes. Markings can withstand harsh environments, reducing the likelihood of fading or wear. That means fewer replacements or returns due to damaged labels. However, not all processes deliver uniform results. Poorly calibrated laser systems can lead to inconsistent marks, affecting the perceived product quality.

Moreover, the precision of laser marking contributes to better performance. Data shows that products with high-quality marks are less likely to fail tests for durability. For compliance with industry standards, such reliability is essential. Yet, businesses may overlook regular maintenance of laser equipment. Inconsistent upkeep can lead to subpar marking, undermining both quality and durability.

Laser marking offers significant environmental advantages over traditional methods. Conventional marking techniques often rely on harmful substances. For example, ink-based methods can produce toxic waste. According to a report by the Environmental Protection Agency (EPA), approximately 150 million tons of hazardous waste are generated annually from industrial processes.

Laser marking eliminates this issue, as it uses light to create permanent markings without chemicals.

Additionally, laser marking is more energy-efficient. Studies show that it can reduce energy consumption by up to 50% compared to traditional methods. This is due to the precision of laser technology, which minimizes material waste. Many businesses are now seeking greener alternatives. The ability to operate without polycarbonate or other pollutants makes laser marking a preferable option.

While many companies embrace this technology, there are hurdles. Initial setup costs can be high. Some businesses struggle to integrate laser marking into existing production lines. This creates a gap between those who benefit from the technology and those left behind. Reflecting on these challenges is crucial for businesses looking to adapt and innovate sustainably.

Laser marking offers profound advantages for businesses aiming to boost brand recognition. It can enhance product traceability, a vital feature in industries such as pharmaceuticals and food. According to a 2022 report by Smithers, companies that utilize clear marking schemes report a 30% increase in consumer trust. Precise markings allow customers to identify legitimate goods, helping combat counterfeiting.

Moreover, companies that adopt laser marking often see improved brand loyalty. Notably, products that feature unique designs or logos stand out on crowded shelves. A survey by Packaging Strategies indicated that 70% of consumers prefer products with noticeable branding. The personalization aspect of laser marking captures attention and resonates with consumers, resulting in longer retention rates. However, not every business maximizes this potential. Lack of understanding about the technology can lead to subpar implementations, hurting brand perception.

Incorporating laser marking into production processes requires investment and training. Many organizations struggle with integrating this technology effectively. Missteps in execution can lead to unclear markings or inconsistent quality, which undermines the benefits. As businesses consider laser marking, reflecting on these challenges can lead to better outcomes. Ensuring precision and consistency is crucial for leveraging its full potential to build trust and brand image.