1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

As we approach 2026, laser etching technology is evolving rapidly. This innovative process shapes how industries produce and design products. With precision and efficiency, laser etching can enhance numerous materials, including metal, wood, and glass.

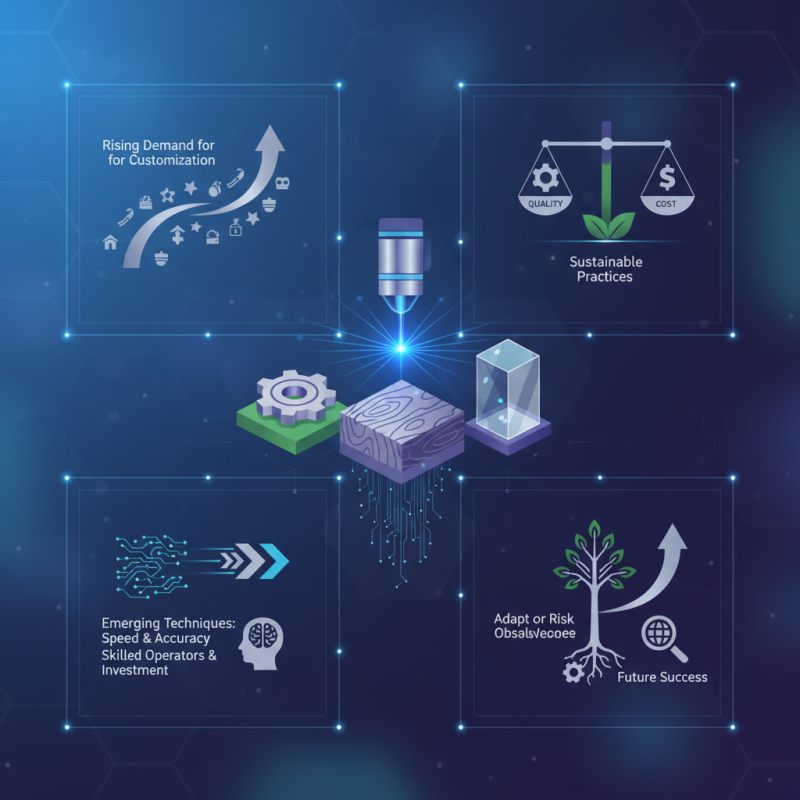

The rising demand for customization drives this trend forward. Businesses look for unique branding methods. However, challenges remain. Companies must balance quality with cost-effectiveness. Additionally, ensuring sustainable practices is crucial. Innovative solutions must cater to environmental concerns while maintaining efficiency.

New developments in laser etching are exciting yet complex. Emerging techniques promise greater speed and accuracy. However, these advancements require skilled operators and significant investment. This landscape forces companies to adapt or risk obsolescence. Understanding the trends in this field will be essential for future success.

In 2026, laser etching technology is experiencing significant advancements. Reports indicate that the global market is expected to reach $5 billion by the end of the year. This growth is driven by increased demand in automotive, aerospace, and electronic sectors. Key innovations include faster processing speeds and enhanced precision. Technologies such as fiber lasers are becoming more prevalent, offering higher energy efficiency.

Tips: Regular maintenance plays a crucial role in ensuring optimal performance. Check for any wear on laser components to prevent unexpected downtime.

Despite these advancements, challenges persist. The high initial cost of equipment can deter small businesses. Additionally, users must stay updated on evolving software for effective operation. Training staff on these technologies remains a hurdle. Many companies struggle with employee turnover, creating gaps in expertise.

Tips: Consider hybrid models to balance cost and technology. Investing in continuous training can create a more skilled workforce.

As we observe the current state of the laser etching industry, it is clear that innovation comes with its own set of challenges. Ensuring a robust supply chain can improve production efficiency. Balancing innovation with economic factors will be key to sustainable growth in this sector.

The world of laser etching is witnessing rapid advancements. Emerging materials play a pivotal role in enhancing this technology. One remarkable trend is the use of biodegradable substrates. These materials not only reduce waste but also allow for intricate designs and eco-friendly applications.

Another area of innovation is the development of nano-coatings. These thin layers can significantly improve adhesion and durability. Using such coatings enables detailed etching on various surfaces, including metals and plastics. The integration of AI in the process may also improve precision and efficiency. Yet, questions arise regarding the long-term sustainability of these materials.

Challenges persist in balancing innovation with environmental impact. Some new techniques may not perform as expected. This inconsistency prompts further exploration. Continuous research is essential to overcome these obstacles. As the industry grows, so does the need for thoughtful evaluation of these emerging trends.

This chart depicts the projected growth percentages of various critical trends in laser etching technology by 2026. Notable advancements include the adoption of innovative materials, increased speed and precision of etching processes, enhanced cost efficiency, and a stronger focus on sustainability within the industry.

Laser etching technology is transforming various industries. From manufacturing to art, its applications are diverse. In manufacturing, companies utilize laser etching for product labeling. It ensures precision and adds a lasting mark on items. Likewise, it helps in creating intricate designs on metal, enhancing aesthetic appeal.

In the medical sector, laser etching serves multiple purposes. Instruments can be etched for better identification. This method reduces errors and enhances safety. For the art community, laser etching provides unique expression. Artists can create detailed patterns on various materials, like wood and glass.

Tips: When considering laser etching, think about your material choice. Different surfaces react differently to laser technology. Test prototypes before proceeding to production. Also, stay updated on new techniques. Seemingly minor improvements can lead to significant enhancements in quality. Reflect on your approach regularly. Look for ways to improve efficiency or design.

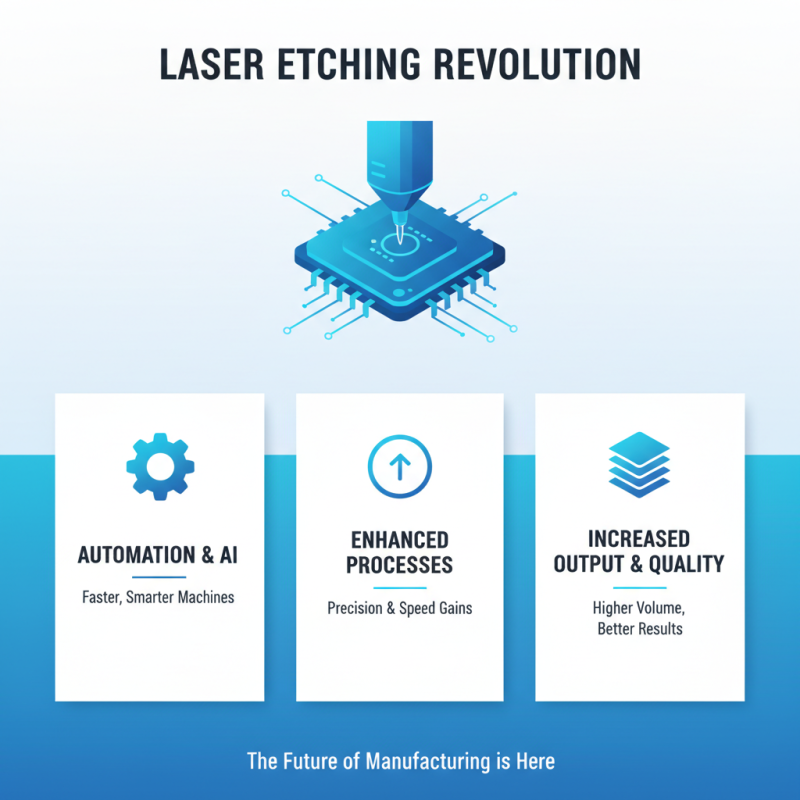

Laser etching is evolving rapidly, thanks to automation and AI. These technologies are changing how etching processes are performed. Machines are faster and more precise than ever. This shift allows for higher volume outputs. At the same time, quality is maintained or even improved.

AI can analyze data to optimize etching parameters. For instance, it checks the depth of engravings in real-time. Adjustments can be made instantly. This leads to reduced waste and more efficient production. However, integrating AI is not without challenges. Companies must invest in training and infrastructure.

Tips:

1. Invest in training your staff to work with AI.

2. Start small when implementing automation.

3. Regularly assess the efficiency of your processes.

As businesses adopt these innovations, they face practical hurdles. Not everyone is familiar with the technology. Some might resist changes. It’s crucial to balance innovation with existing workflows. Exploring these trends helps drive the industry forward.

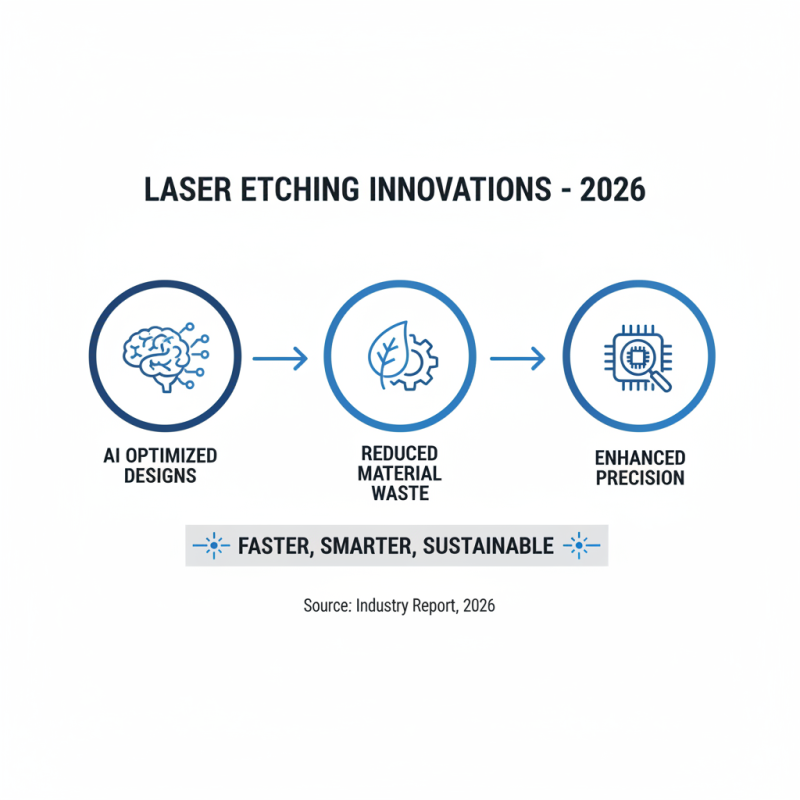

Laser etching technology is evolving rapidly. In 2026, we expect notable innovations that will change industries. One key trend is the use of artificial intelligence. AI can optimize designs for laser etching processes. This may cut down on wasted materials. Precision is paramount. Better algorithms will enhance accuracy.

Another notable trend is sustainability. Companies are leaning towards eco-friendly materials. This shift reflects a growing awareness of environmental impact. Laser etching using renewable resources can reduce waste significantly. However, sourcing these materials is often challenging. It requires careful consideration and commitment.

Integration with IoT is also on the horizon. Smart devices can monitor laser etching processes in real-time. This could lead to greater efficiencies. But, the technology must address security concerns. Data leaks could have severe consequences. As innovations unfold, the balance between progress and potential risks remains crucial. Exciting times lie ahead, yet caution is necessary.