1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

The world of laser engraving machines is rapidly evolving. Industry expert John Smith recently stated, "Innovation drives the laser engraving machine sector forward." This reflects the dynamic nature of the market and its technologies. As we approach 2026, several key trends are reshaping how businesses and individuals use these tools.

One significant trend is the rise of automation in laser engraving machines. Automation enhances precision and boosts productivity. This change allows users to achieve intricate designs faster and with less manual effort. However, some users might struggle with the learning curve associated with automated systems.

Additionally, sustainability is becoming a priority in the laser engraving machine industry. Manufacturers are focusing on eco-friendly materials and energy-efficient machines. This shift can be challenging for those accustomed to conventional practices. Nevertheless, it represents a pivotal move towards responsible manufacturing. These evolving trends highlight both the potential benefits and the challenges users face in adapting to new technologies.

The laser engraving technology landscape is rapidly evolving. As of 2026, several innovations are shaping the industry. One notable trend is the rise of fiber laser systems, which are proving to be highly efficient. According to recent industry reports, these systems can reduce marking time by up to 50%. This efficiency unlocks new opportunities for businesses seeking to enhance productivity.

Another significant trend is the integration of AI and machine learning with laser engraving machines. These technologies allow for better precision and tailored designs. With AI, machines can optimize engravings in real time, making adjustments based on material type and thickness. Reports highlight that companies using AI can improve production rates by 30%. However, the reliance on advanced technology also raises concerns about skill gaps in the workforce.

Sustainability continues to be a critical focus, with advancements in eco-friendly materials. Many manufacturers are experimenting with biodegradable options for engraving substrates. Yet, implementing these materials can be challenging. They often require different laser settings, which can lead to trial and error. Balancing eco-friendliness with operational efficiency will remain a hot topic in 2026.

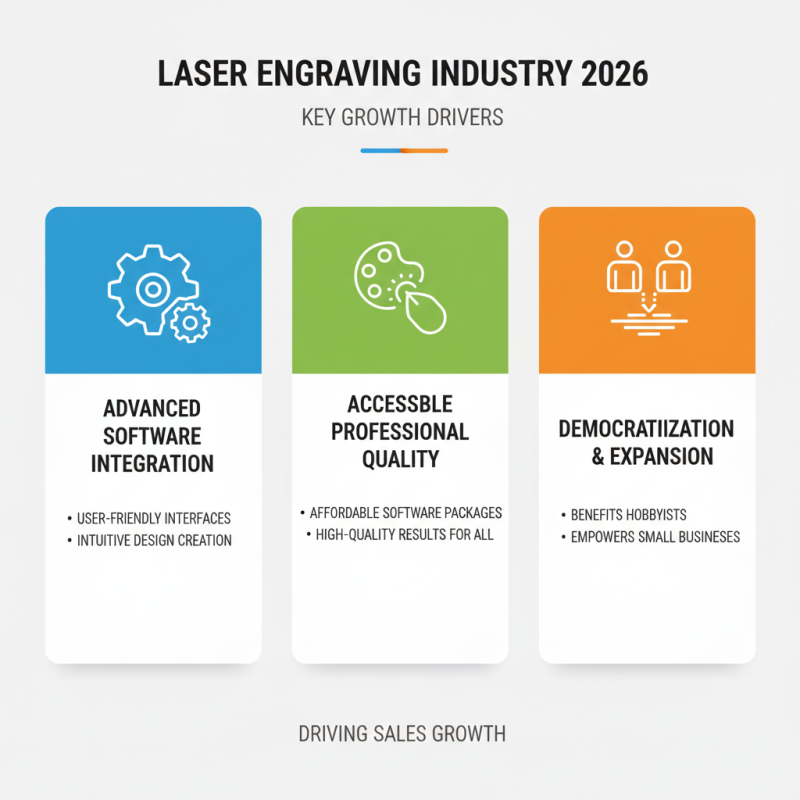

The laser engraving industry is rapidly evolving. In 2026, several key features will significantly impact sales growth. One major trend is the integration of advanced software. User-friendly interfaces allow even beginners to create intricate designs. Affordable software packages make professional-quality work accessible. This democratization benefits hobbyists and small businesses alike.

Another critical feature is portability. Lightweight models allow users to engrave on-site. This flexibility attracts artisans who travel for events and exhibitions. Additionally, enhanced mobile connectivity means engraving can be done anywhere. However, while these features drive sales, there are challenges. Many entry-level machines may not withstand heavy use. Users must consider longevity and support options.

Customization is also on the rise. Customers want personalized products and unique designs. Machines that offer versatile engraving options will see increased demand. However, maintaining a balance between quality and speed can be tricky. Fast production sometimes leads to compromises in detail. As trends shift, users must remain adaptable and aware of their machine's limitations.

Industry 4.0 is transforming laser engraving machinery. This revolution focuses on smart technology and automation. Companies are increasingly adopting laser engraving solutions that integrate advanced software and connectivity features. A report from Market Research Future states that the global laser engraving market is projected to grow by over 8% annually by 2026. This data highlights a significant rise in demand for such technology.

Smart factories now utilize real-time data analytics. This leads to improved efficiency and precision in laser engraving. Sensors and IoT (Internet of Things) devices monitor machine performance continuously. However, this high level of automation can sometimes lead to over-reliance on technology. There are concerns about potential job displacements and the skill gap in the workforce as machinery becomes more sophisticated.

Moreover, the sustainability aspect is becoming crucial. Laser engraving processes are more eco-friendly compared to traditional methods. A study by Grand View Research indicates that companies are looking for greener solutions. Yet, the transition to Industry 4.0 comes with challenges. Businesses must balance innovation with responsible practices. This evolution in laser engraving technology requires ongoing evaluation and adjustment to address these growing concerns.

As we move towards 2026, laser engraving continues to evolve. One significant trend is the exploration of emerging materials. These materials offer new opportunities for artists and manufacturers alike. Unique options such as biodegradable plastics and sustainable woods are gaining traction. These choices not only promote environmental responsibility but also inspire creativity.

However, not all new materials perform as expected. Some may not engrave as smoothly, leading to inconsistent results. Artists might find themselves reconsidering their designs. The shift requires experimentation and adaptability. Understanding how different materials react to laser engraving systems is crucial. Mistakes can provide valuable lessons for future projects.

Innovations in the field also include advanced composites and metals. These materials can produce stunning visual effects. Yet, they often demand more from the machines. Users may need to adjust settings frequently. Finding the right balance between speed and quality can be challenging. As the industry grows, so does the complexity of working with new materials. Continued learning is vital for success.

| Material Type | Engraving Quality | Market Demand (2026) | Sustainability Rating |

|---|---|---|---|

| Acrylic | High | Increasing | Moderate |

| Wood | Excellent | Stable | High |

| Glass | Very High | Growing | Moderate |

| Leather | High | Consistent | Moderate |

| Metal | Excellent | Increasing | Low |

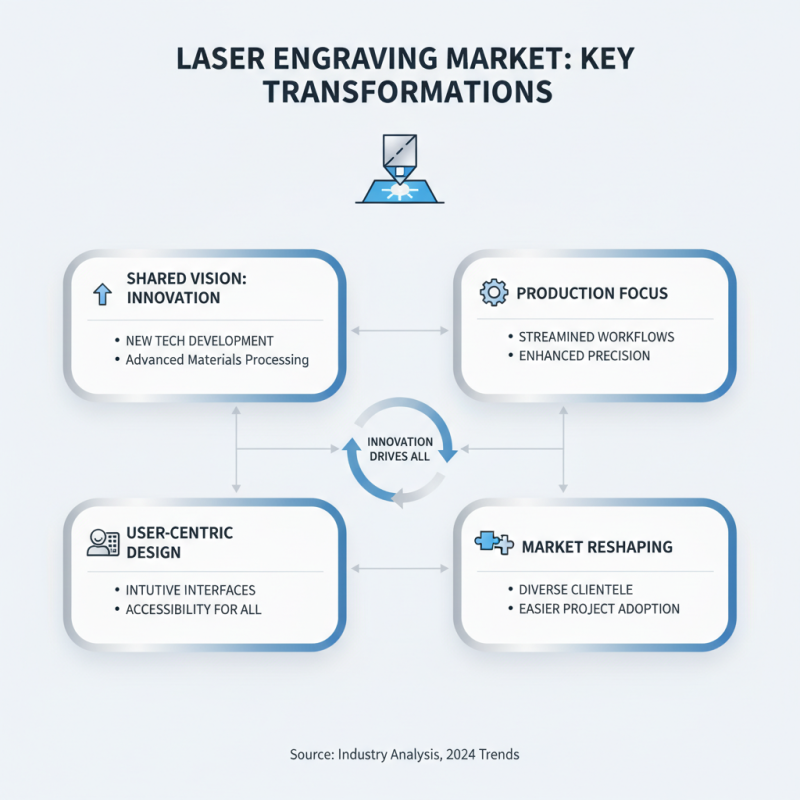

The laser engraving market is witnessing significant transformations. Among the top manufacturers, a shared vision for innovation emerges. Companies aim to streamline production while enhancing precision. They recognize the importance of user-friendly technology to attract a diverse clientele. This shift is reshaping how businesses approach engraving projects.

One trend is the move towards more compact, efficient machines. Smaller spaces do not equal less capability. These machines maintain high performance while being easy to operate. However, some manufacturers face challenges in balancing cost and functionality. As competition grows, the pressure to innovate increases. Companies must reflect on their values to keep up with demanding consumer expectations.

Sustainability is another focal point. Eco-friendly materials are becoming essential in the engraving process. Companies explore how to reduce waste while delivering quality products. However, the quest for sustainability can be complex. Choices made today impact the future of the industry. Addressing these challenges requires a thorough examination of current practices. Understanding the market's evolution is vital for manufacturers aiming to lead in laser engraving.