1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

In the world of manufacturing and metalworking, precision is paramount. The advancements in laser welding technology have made it a game changer for many industries. Expert Joe Anderson, a renowned figure in the laser welding field, states, "A good laser welder can transform the quality of your work." This highlights the importance of choosing the right model.

The year 2026 is bringing exciting innovations in laser welders. As companies explore new options, they seek models that offer unparalleled efficiency. Each laser welder has unique features, making it crucial to identify which suits your specific needs. However, not all models deliver as promised. Some fall short, leaving users unsatisfied.

Selecting the right laser welder can be daunting. Many options exist, and not all provide the desired results. Businesses must weigh their choices carefully. The best models blend precision and speed, enhancing productivity. Still, challenges remain. Finding a laser welder that aligns with your expectations requires thorough research and consideration.

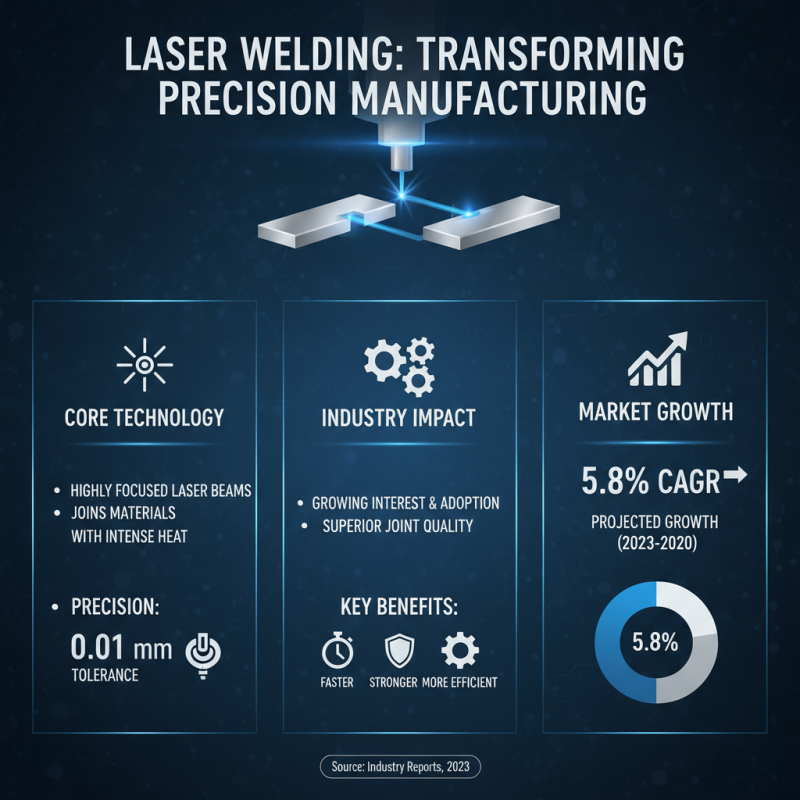

Laser welding technology has transformed precision manufacturing significantly. This method uses highly focused laser beams to join materials. The precision of laser welders can reach tolerances within 0.01 mm. Current industry reports highlight a growing interest in laser technology, projecting the market to expand at a compound annual growth rate (CAGR) of 5.8% through 2030.

The advantages of laser welding are numerous. Firstly, this method minimizes heat input, which reduces the risk of warping in delicate materials. It is suitable for various metals, including aluminum and titanium. Additionally, laser welding often leads to faster production cycles. Studies have shown that companies can increase productivity by up to 30% by integrating laser welders into their workflows.

However, laser welding isn't without its challenges. The initial setup cost can be prohibitive, and skilled operators are essential. Not every application is suitable for laser welding. Some materials may require more traditional methods to ensure quality. Continuous evaluation of the process is vital. Companies should weigh both the advantages and limitations to optimize their welding operations effectively.

Choosing the right laser welder can significantly impact your projects. When evaluating options, consider the power output. Higher wattage allows for faster welding, but it also demands more skill to handle properly. Opting for lower wattage may offer more control and precision, especially for intricate tasks. This balance is crucial for achieving effective results.

Material compatibility is another essential feature. Different welders handle various materials like steel, aluminum, or plastic. Ensure your chosen model can accommodate the specific materials you plan to work with. Additionally, look for options with adjustable settings. Customization is vital for adapting to different thicknesses and types of welds.

Portability matters too. A lightweight welder is easier to move for job sites or projects around your workspace. However, smaller models may sacrifice power or features. Reflect on your actual needs and workspace before committing to a model. Take time to explore reviews to get insights on usability and performance. Not all machines will meet everyone's expectations.

| Model | Wattage | Max Thickness (mm) | Pulse Frequency (Hz) | Cooling Type | Weight (kg) |

|---|---|---|---|---|---|

| Model A | 1500W | 5 | 20 | Water | 60 |

| Model B | 2000W | 8 | 25 | Air | 65 |

| Model C | 1000W | 4 | 15 | Water | 50 |

| Model D | 3000W | 10 | 30 | Air | 70 |

| Model E | 2500W | 9 | 22 | Water | 75 |

As we approach 2026, precision laser welders continue to evolve, becoming essential tools in manufacturing. Industry reports indicate that over 70% of manufacturers prioritize precision when selecting welding technology. Laser welders offer high accuracy, minimizing the heat-affected zone, which preserves material integrity. In tight tolerances, even a slight misalignment can lead to product failure, making precision crucial.

Among the best models in 2026, features such as adjustable power settings and advanced cooling systems stand out. The data shows that models with multi-wavelength capabilities enhance versatility. However, many users still struggle with mastering the settings. The learning curve can be steep, leading to suboptimal results. Careful attention to technique is vital.

New technology introduces exciting possibilities, but not without challenges. Many operators report difficulty in maintaining consistency across different materials. While laser welding excels in precision, it sometimes fails to penetrate thicker sections effectively. This inconsistency could affect overall production efficiency. As manufacturers seek the best fit for their needs, the balance of precision and versatility remains a focus.

When it comes to laser welders, efficiency is crucial. Recent data shows that efficiency can vary significantly among different models. For instance, a leading industry report indicates that high-end laser welders can achieve up to 90% energy efficiency. This is a stark contrast to lower-tier models, which often hover around 70%.

Precision is another critical aspect. Many professionals require welders that can produce clean, consistent seams. Surprisingly, some models may struggle to maintain this precision over extended periods. Users often report inconsistencies in bead width and depth. Therefore, comparing weld speeds and quality across models is essential.

Cost-efficiency also plays a role. The initial investment in advanced laser technology can be substantial, but the long-term savings on materials and labor can offset that. Some studies suggest that investing in more efficient equipment can reduce operational costs by up to 25%. However, businesses must carefully analyze their specific needs. A mismatch between equipment capability and task requirements can lead to inefficiencies.

When evaluating the best laser welder models of 2026, user reviews provide valuable insights. Many users highlight the importance of precision. A well-designed laser welder can create clean, strong welds without excessive heat. This feature is especially crucial for delicate materials. Some users report frustrations with calibration issues. Adjusting the settings can feel tedious and time-consuming.

Performance evaluations also reveal mixed experiences. Certain models excel in speed but lack consistent quality. Users complain about sporadic weld strength. Others find their ideal balance between efficiency and durability. Detailed user feedback often emphasizes trial and error in finding the right settings. It's not uncommon for users to share their struggles with finding optimal materials.

Some models have robust functionalities, but they may require advanced skills to operate. Beginners might feel overwhelmed by complex features. This reality underscores the importance of user reviews when choosing a laser welder. Potential buyers should read carefully and consider their specific needs. Each user’s journey is unique, filled with learning experiences and occasional setbacks.