1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

In recent years, the demand for glass etching machines has surged, revealing a vibrant market for both hobbyists and professionals. According to a report by MarketsandMarkets, the global glass processing market is expected to grow significantly, driven by advancements in technology and increasing customization needs. Professionals in the field, like John Smith, a renowned expert in glass manufacturing, state, "The right glass etching machine can transform simple designs into stunning works of art."

Choosing the best glass etching machine requires careful consideration of several factors. The variety of machines available can be overwhelming. If you rush this choice, you might end up with a model that doesn’t meet your specific needs. Performance varies widely among brands and models, affecting precision and ease of use.

As the industry evolves, more features are being added to glass etching machines, but not all of them are necessary. Therefore, understanding your requirements is crucial. Selecting a machine simply based on brand hype could lead to disappointment. Balancing features with actual usability is key to making a smart purchase.

In 2026, the glass etching machine market boasts a variety of brands catering to hobbyists and professionals alike. Industry reports indicate that the market has grown significantly, with an expected CAGR of 5% through 2028. This growth highlights the increasing interest in glass etching as a craft and a viable business opportunity for many.

Popular brands emphasize user-friendly features. Some machines come with integrated software for design, while others offer manual controls for more hands-on etching. However, not all machines deliver consistent results. Users often report uneven etching depth, especially with cheaper models. The materials used in construction can significantly impact performance. For instance, metal and higher-grade plastics tend to yield better results compared to cheaper alternatives.

Customer feedback also reveals common pain points. Some brands have issues with customer service and spare parts availability. While some machines might shine in reviews, they can fall short when it comes to long-term durability. Engravers must weigh these factors carefully, as the perfect choice varies from user to user. Ultimately, those entering the market should do thorough research before committing.

Choosing the right glass etching machine is essential. There are several key features to consider. The type of design you want to create matters. Some machines are better for intricate designs, while others work best with basic shapes. Make sure you think about your projects and pick accordingly.

Power is another crucial feature. A higher wattage usually means quicker etching. However, more power can also mean less precision. You might end up with rough edges if you're not careful. Look for machines that balance power with control to suit your needs.

Ease of use is vital, especially for beginners. A user-friendly interface can save you time and frustration. Some machines come with software to help. Others might require extra setup. Check reviews and user experiences to gauge practicality. You want a machine that helps you, not one that complicates your tasks.

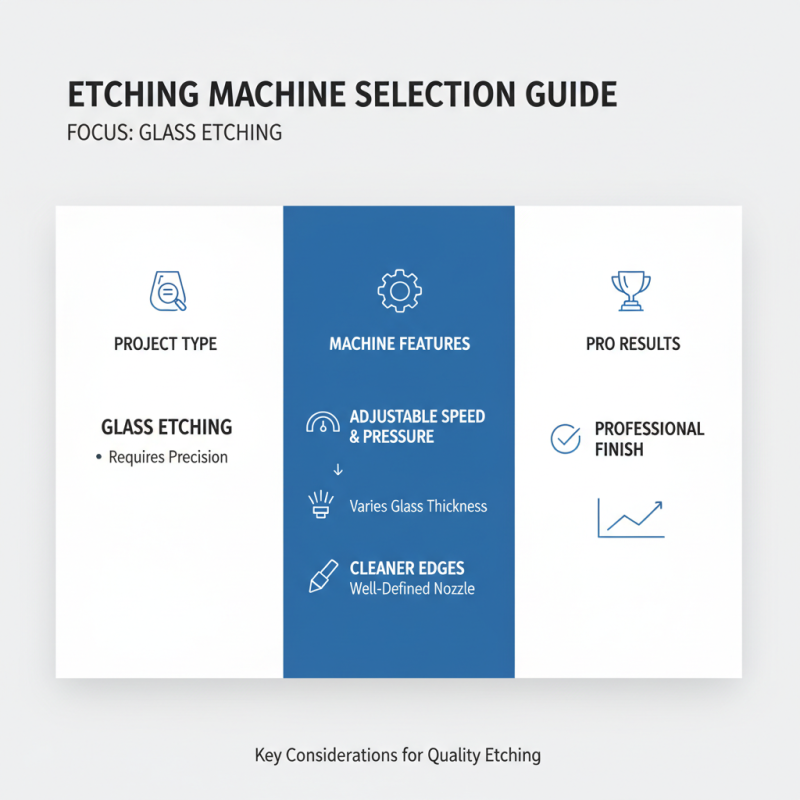

When selecting an etching machine, consider the type of projects you want to undertake. Glass etching requires precision. A machine with adjustable speed and pressure is essential. These features allow you to work on various glass thicknesses. Studies show that machines with a well-defined nozzle can create cleaner edges. This is crucial for achieving professional results.

Understand your material needs. If you plan to work with different glass types, a versatile machine is key. Opt for a model that can handle both soft and hard glass. According to industry reports, versatility enhances productivity by up to 40%. Take note of machine size. Compact models may save space but could limit project scope. Evaluate how often you’ll use the machine. Frequent users might prefer a more robust machine.

Budget also plays a significant role. Prices can range widely, impacting your choices. Be wary of cheaper options that may lack durability. Repair costs can quickly exceed the initial savings. A study from the Glass Etching Association revealed that over 30% of users regret not investing in higher quality machines. Consider all these factors carefully before making a purchase.

In 2026, the glass etching machine market continues to grow. Recent data shows an annual growth rate of around 6.5%. This indicates a rising demand for personalized glass products. Many hobbyists and professionals seek quality machines for creative projects. However, not all machines meet performance expectations.

A comparative analysis reveals several key features that matter most. Power levels, etching speed, and user-friendliness are crucial. The best machines often have adjustable power settings. This flexibility allows for different glass types and designs. Ease of use can impact a user's experience. Many machines boast intuitive controls but may lack clear instructions.

Reviews also highlight concerns about durability. Some models have reported wear and tear after light use. This reflects a need for careful evaluation before purchase. Potential buyers should also consider support services. Access to replacement parts can prolong the machine's life. The right choice can lead to satisfaction, while a poor one may result in frustration.

Maintaining your glass etching machine is crucial for ensuring its longevity. Regular cleaning is essential. Dust and residue can affect performance. Use a soft brush to remove particles from moving parts. Wipe surfaces with a damp cloth to prevent buildup. Over time, neglect can lead to malfunction.

Check belts and cables for any signs of wear. Replace them if you notice fraying or damage. A loose belt can cause inconsistencies in your etching. Additionally, inspect the power source. Fluctuating electricity can harm your machine’s components.

Lubricate the moving parts regularly. A simple application of machine oil can enhance performance. However, be careful not to overdo it; excess oil can attract dust. Tracking usage can help you know when maintenance is needed. Write down the hours of operation. This will aid in scheduling timely checks. Remember, small mistakes can lead to bigger problems later. Keep a close eye on your equipment.

| Model | Power | Etching Depth | Speed | Weight | Price |

|---|---|---|---|---|---|

| Model A | 50W | 0.5 mm | 30 mm/s | 12 lbs | $199 |

| Model B | 60W | 0.8 mm | 25 mm/s | 10 lbs | $250 |

| Model C | 70W | 1.0 mm | 40 mm/s | 15 lbs | $299 |

| Model D | 80W | 1.2 mm | 50 mm/s | 18 lbs | $349 |

| Model E | 90W | 1.5 mm | 60 mm/s | 20 lbs | $399 |