1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

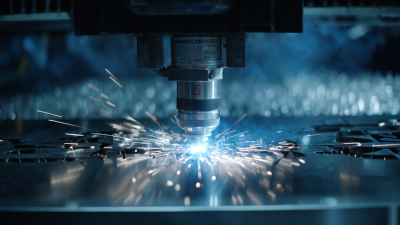

As we move towards 2025, the landscape of laser etching continues to evolve, bringing forth innovative techniques and applications across various industries. This cutting-edge technology, which harnesses the power of precise and efficient material removal, is gaining traction in manufacturing, craft making, and personalized products. Understanding the top laser etching trends is essential for professionals and hobbyists alike, as it equips them with the knowledge needed to enhance their projects, achieve superior results, and stay competitive in a rapidly changing market.

In this exploration of the latest trends, we will delve into emerging techniques, materials, and applications that are shaping the future of laser etching. From advancements in software and machinery to the integration of eco-friendly practices, the focus is on optimizing both efficiency and sustainability. By staying informed about these trends, individuals and businesses can make informed decisions that align with their objectives, ensuring that their projects benefit from the latest innovations in laser etching technology. Whether you are looking to enhance product customization or streamline your production processes, this guide will provide the essential insights to elevate your laser etching endeavors.

As we look forward to 2025, the landscape of laser etching is poised for significant transformation driven by emerging technologies. One of the most notable advancements is the integration of artificial intelligence (AI) into laser etching systems. AI can optimize the etching process by analyzing material characteristics and adjusting parameters in real-time to achieve precise results. This not only enhances the quality of etching but also increases efficiency, allowing for faster production times and reduced waste.

Another key trend is the rise of 3D laser etching capabilities. This technology allows for intricate designs and textures to be created on various materials, pushing the boundaries of traditional etching methods. By utilizing advanced laser systems, manufacturers can now produce three-dimensional effects that add depth and complexity to their projects. This trend is particularly relevant in industries such as fashion, automotive, and electronics, where customization and aesthetic appeal are paramount.

Additionally, sustainability is becoming an essential consideration in laser etching technologies. Researchers are developing eco-friendly materials and processes that minimize environmental impact while maintaining high-quality standards. Innovations such as water-based inks and energy-efficient laser systems are gaining traction, reflecting a broader industry shift toward practices that prioritize environmental responsibility. As these technologies emerge, they not only enhance the capabilities of laser etching but also align with the growing demand for sustainable manufacturing practices.

Laser etching has emerged as a transformative technology across various sectors, offering precision and versatility in marking and engraving. According to a recent market report from Fortune Business Insights, the global laser marking market is projected to reach USD 4.18 billion by 2026, growing at a CAGR of 6.5% from 2019 to 2026. This growth is largely fueled by the expanding applications of laser etching in industries such as automotive, aerospace, electronics, and medical devices. The ability to produce high-quality, enduring marks on a wide range of materials—including metals, plastics, and glass—positions laser etching as a critical tool for manufacturers aiming to enhance product traceability and branding.

In the medical sector, laser etching plays a pivotal role in ensuring compliance with regulatory standards. Engravings on surgical instruments and medical devices must provide clear identification while maintaining the integrity of the product. The precision of laser technology not only meets these stringent requirements but also helps in minimizing contamination risks during the manufacturing process. Additionally, in the electronics industry, laser etching enables the creation of intricate designs for circuit boards and microchips, greatly improving reliability and performance. As industries continue to adopt innovative laser solutions, the demand for skilled professionals who understand these technologies will also increase, highlighting the importance of training programs and expertise in capitalizing on these advancements.

As sustainability becomes increasingly crucial in manufacturing and production processes, the laser etching industry is witnessing a significant shift towards eco-friendly practices. These trends not only aim to minimize waste but also prioritize the efficient use of energy and materials. By integrating sustainable methodologies, laser etching applications are evolving to produce lower emissions and reduced energy consumption, appealing to environmentally conscious consumers and businesses alike. The emphasis is now on utilizing renewable energy sources to power laser engraving machines and adopting materials that are either biodegradable or recyclable.

Innovative advancements in laser etching technology are further empowering sustainability initiatives. For instance, the development of more precise laser systems allows for less material wastage during the engraving process, improving overall efficiency. Additionally, businesses are exploring sustainable substrates made from recycled materials or non-toxic sources, which align with green manufacturing standards. This proactive approach not only meets regulatory requirements but also enhances the reputation of companies committed to sustainable development, making them more competitive in the market. As these trends continue to shape the future of laser etching, the collaboration between technology and sustainability will be pivotal for upcoming projects.

The landscape of laser etching is continuously evolving, driven by advancements in materials that enhance both the technique's precision and capability. According to a report by ResearchAndMarkets, the laser engraving market is projected to reach $4.5 billion by 2025, indicating a compound annual growth rate (CAGR) of 7.5%. This growth is being fueled by the increasing adoption of materials such as ceramics, metals, and polymers, which provide unique properties for diverse applications. For instance, ceramics offer exceptional durability and heat resistance, making them suitable for high-temperature environments, while metals remain popular due to their recyclability and strength.

Moreover, biodegradable polymers are gaining traction in the industry, reflecting a significant shift toward sustainable practices. As reported by Grand View Research, the biodegradable plastics market is expected to grow at a CAGR of 12.6% from 2021 to 2028, indicating that industries are becoming more environmentally conscious. These materials not only align with global sustainability goals but also allow for intricate designs and patterns through laser etching that were previously challenging to achieve. The evolution of these key materials marks a pivotal journey toward enhancing efficiency, aesthetic appeal, and sustainability in laser etching projects, providing exciting opportunities for innovation across various sectors.

As we venture towards 2025, the landscape of laser etching technology is poised to face both significant challenges and unprecedented opportunities. One of the primary challenges is the rapid pace of technological advancement, which necessitates constant adaptation among manufacturers and users alike. According to a recent industry analysis, the global laser etching market is projected to reach $4.3 billion by 2026, with a CAGR of 7.5%. This highlights the urgency for professionals to stay informed about the latest innovations and capabilities.

In addition to technological hurdles, environmental regulations are becoming increasingly strict. This presents challenges in terms of material sourcing and waste management. However, this also opens up opportunities for cleaner technologies and sustainable practices within the industry. For instance, the integration of eco-friendly materials in laser etching processes not only meets regulatory standards but also appeals to a growing customer base focused on sustainability.

**Tips for adapting to these trends include:**

1. Invest in ongoing education and training for your team to keep pace with technological advancements.

2. Explore partnerships with suppliers who focus on sustainable practices to enhance your product offerings.

3. Regularly monitor industry reports and market analyses to identify emerging trends early and adapt your strategies accordingly.

| Trend | Description | Challenges | Opportunities |

|---|---|---|---|

| Increased Material Compatibility | Expanding the range of materials that can be laser etched. | Need for specialized equipment and processes for different materials. | Potential to serve diverse industries and applications. |

| Automation and Integration | Incorporating AI and robotics for efficiency in laser etching. | High initial investment and training for staff. | Increased production capacity and reduced labor costs. |

| Sustainability Practices | Focus on eco-friendly materials and processes in laser etching. | Regulatory challenges and material sourcing issues. | Attracting green-conscious consumers and businesses. |

| Customization and Personalization | Growing demand for bespoke products and designs. | Managing varying customer expectations and logistics. | Enhanced customer engagement and loyalty through unique offerings. |

| Smart Technology Implementation | Using IoT to monitor and optimize laser etching processes. | Cybersecurity risks and data management challenges. | Data-driven insights leading to improved efficiency. |